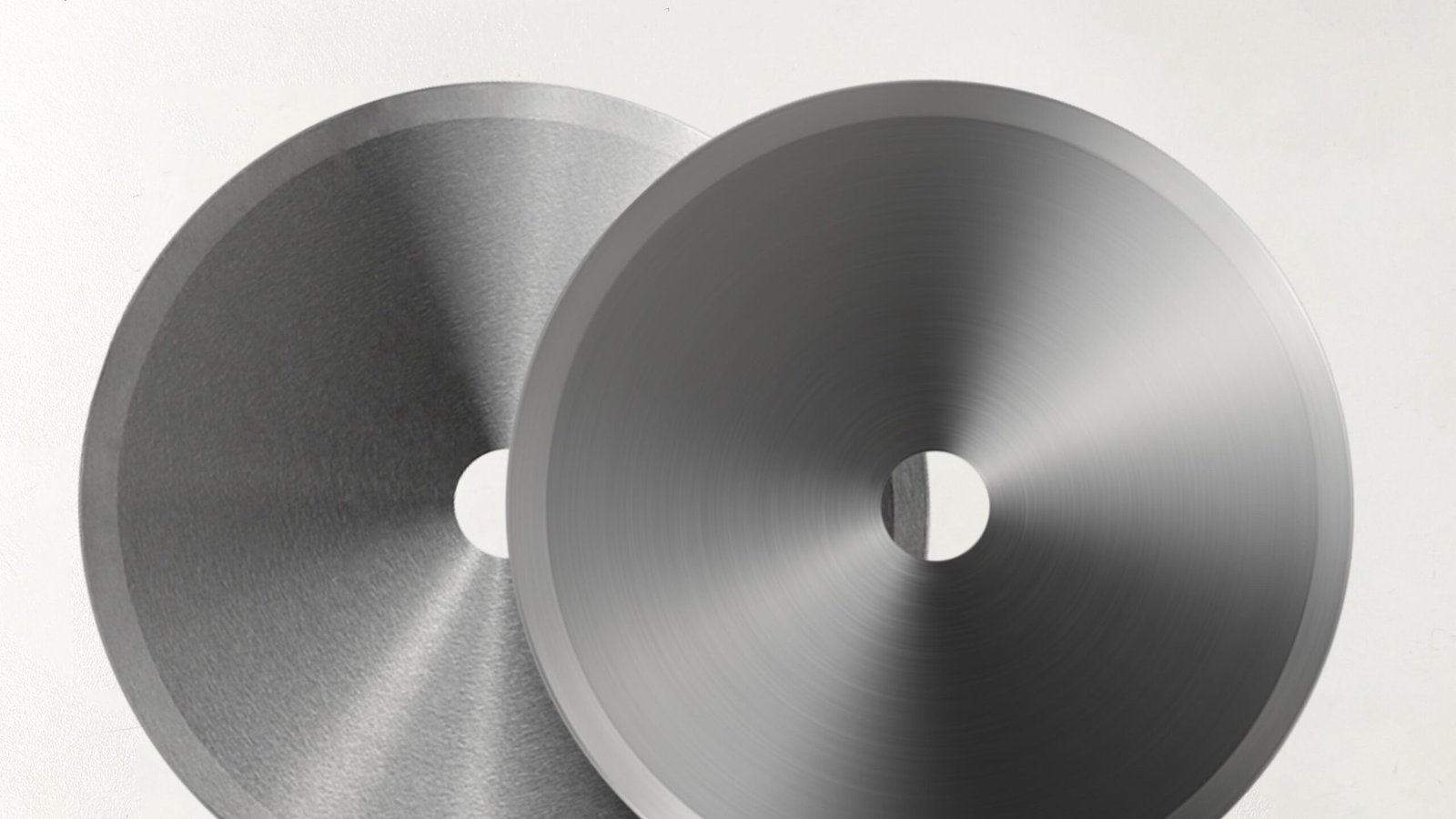

Your production line is slowing down. Circular blades are failing early, causing unexpected stops and costing you money. The problem might be hidden inside the blade itself.

The primary inherent factors are improper material selection, low manufacturing precision, internal defects from heat treatment, and poor coating quality. These hidden issues lead to chipping, rapid dulling, and sudden failures, which directly cause production inefficiency.

I often speak with customers who are frustrated with their blade performance. They've optimized their machines and processes, but the blades still don't last. The truth is, not all blades are made equal. The issues that cause the most downtime are often created long before the blade ever gets to your factory. Let's explore these built-in problems one by one. Understanding them will help you choose a better, more reliable blade.

How Can The Wrong Blade Material Cut Your Profits?

Your blades are chipping and wearing out too fast. This means more spending on replacements and more downtime. The raw material of the blade is often the root cause.

Choosing the wrong blade material, like recycled tungsten steel1, creates an imbalance between hardness and toughness2. This leads to early chipping and cracking, which can reduce the blade's service life by 20% to 40% and stop your production line.

I remember working with a client in the packaging industry who had this exact issue. They were cutting a tough composite material and their blades were chipping constantly. Their supplier had sold them a blade made from recycled tungsten steel. On paper, it had very high hardness, which seemed good. But in reality, it was too brittle to handle the cutting pressure. The blades were losing their edge after just a few days, a massive drop from the performance they expected. The low initial price of the recycled material ended up costing them much more in the long run because of the frequent line stops and blade changes.

The Balance Of Hardness and Toughness

The best blade material is not always the hardest one. It's about finding the right balance for your specific application.

- Hardness: This is the material's ability to resist abrasive wear. A harder blade stays sharp longer when cutting soft or abrasive materials.

- Toughness: This is the material's ability to resist impact and shock without breaking. A tougher blade is less likely to chip when cutting hard or inconsistent materials.

Recycled materials often have inconsistent internal structures, which makes them brittle. We solved my client's problem by switching them to a PASSION blade made from virgin, ultra-fine-grained tungsten carbide. The finer grain structure provides much better toughness while maintaining excellent hardness. We also adjusted the cobalt binder content to further optimize it for their application. The result was a blade that lasted over 30% longer and eliminated the chipping problem entirely.

Why Does A Blade's Precision Matter So Much For Performance?

You see poor cut quality, and the machine sounds strained. The blade seems sharp, but it's not working right. The problem could be tiny imperfections you can't even see.

Low manufacturing precision, such as a rough cutting edge or poor concentricity, increases friction and vibration. This causes the blade to dull much faster, leading to inaccurate cuts, more machine stress, and frequent production stops for blade changes.

Manufacturing precision is a factor that many people overlook. They assume if a blade is new, it's perfect. But the quality of the grinding and finishing makes a huge difference. I had a customer who was cutting thin plastic film. They were getting jagged edges and material stretching. We examined their blades under a microscope and found that the cutting edges were rough. They weren't slicing the film cleanly; they were tearing it on a microscopic level. This extra friction was also generating heat, which caused the blade to dull very quickly. A blade is not just a piece of shaped metal; it's a precision instrument.

Precision's Direct Impact On Cutting

Two key aspects of precision have the biggest effect on your production line's efficiency.

| Precision Factor | What It Is | How It Causes Problems |

|---|---|---|

| Edge Finish | The smoothness of the cutting edge surface. | A rough edge increases friction, generates heat, and tears material. |

| Concentricity | How perfectly round and centered the blade is. | Poor concentricity causes wobble, vibration, and uneven wear. |

By switching to a PASSION blade with a mirror-finish edge3 and extremely tight concentricity tolerances, my client was able to solve their cutting issues. The cuts became perfectly clean. The blades also lasted much longer because the low-friction edge generated less heat. It's a clear example of how investing in a high-precision tool pays off with better product quality and less downtime.

What Hidden Flaws Inside Your Blade Are Causing It To Fail?

A blade breaks suddenly, without any warning or visible wear. This type of failure is dangerous and brings production to a halt. The cause is likely an invisible defect inside the blade.

Defects from the creation process, like tiny internal voids or locked-in stress, create weak points. These hidden flaws act as starting points for cracks, causing sudden, unpredictable blade failure even under normal working conditions.

The internal structure of a blade is just as important as its shape or sharpness. For carbide blades, the sintering process is critical. This is where metal powder is fused together under intense heat and pressure to form a solid piece. If this process is not perfectly controlled, it can create microscopic air pockets, or voids, inside the material. I once investigated a case where a customer's blades were cracking in half. The wear on the edge was normal, but they would just snap. An analysis showed the blades were full of these tiny voids. Each void was a weak spot. Under the stress of cutting, a small crack would start at a void and quickly spread through the entire blade.

The Invisible World Of Internal Defects

You can't see these problems with the naked eye, but they have a huge impact on blade strength and reliability.

- Micro-Voids: These are tiny empty spaces left over from improper sintering. They reduce the blade's overall strength and create stress points where cracks can form.

- Residual Stress: If a blade is cooled too quickly or unevenly after heat treatment, stress gets locked into the material. This internal tension makes the blade brittle and much more likely to crack under pressure.

- Inhomogeneity: This means the material structure isn't consistent. Some areas might have larger carbide grains or less binder. These uneven spots wear out faster and can lead to localized failure.

Is Your Blade's Protective Coating Actually Causing Problems?

You bought a coated blade for better performance, but it's peeling off. Now it wears out even faster than a standard blade. The problem isn't the idea of a coating, but its quality.

A poorly applied coating will fail. If the blade surface isn't prepared correctly, the coating will peel away. If the coating itself is too thick or brittle, it will crack under pressure, exposing the blade to accelerated wear.

Coatings are a fantastic way to boost blade performance, but only if they are done right. A customer in the textile industry came to me with blades where the coating was peeling off in sheets. They were cutting an abrasive synthetic fabric, and they needed the coating's wear resistance. But the peeling was exposing the raw blade material, which then wore down almost instantly. The issue was poor surface preparation by their previous supplier. The blade's surface wasn't cleaned properly before the coating was applied, so it never formed a strong bond. The coating was just sitting on top of the blade, not bonded to it. It was doomed to fail.

The Keys To A Successful Coating

A good coating is more than just a single layer; it's a complete system.

- Surface Pretreatment: The blade surface must be perfectly clean and properly textured. This ensures the coating has something to hold onto. Any oil, dust, or residue will prevent a strong bond from forming.

- Deposition Process: The parameters used to apply the coating, like temperature and pressure, must be precisely controlled. The wrong parameters can create a coating that is brittle or has internal stresses.

- Thickness Control: There is an optimal thickness for every coating. If it's too thin, it won't provide enough protection. If it's too thick, it can become brittle and more likely to chip, taking a piece of the blade with it.

At PASSION, we see coating as an integral part of the blade's design. Our multi-stage process ensures a perfect bond and optimal thickness, so the coating enhances the blade's life instead of shortening it.

Conclusion

Choosing the right blade is more than looking at the price. Material, precision, internal quality, and coating are key. At PASSION, we perfect these factors for reliable, efficient cutting performance.