Are you frustrated with inconsistent cutting performance? This problem often leads to material waste and costly downtime, directly hurting your production efficiency. OEM industrial blades1 are the solution you need.

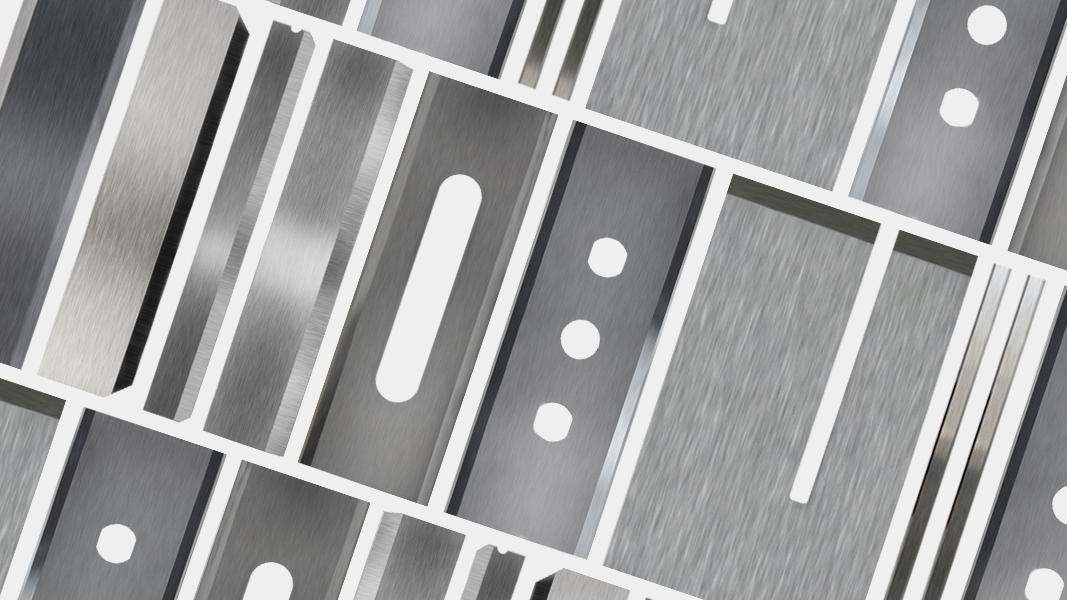

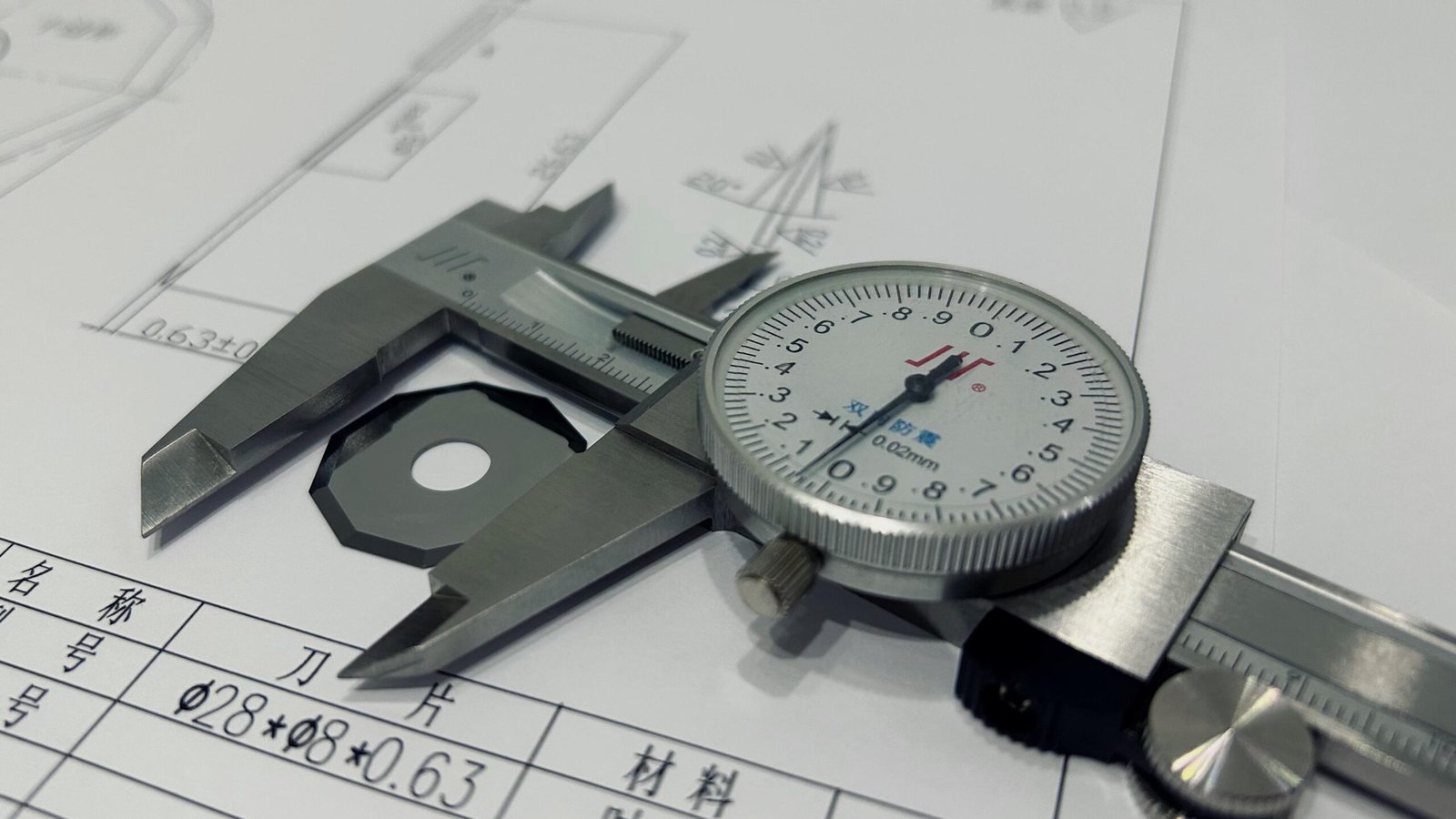

OEM (Original Equipment Manufacturer) industrial blades are custom-made cutting tools. They are produced by a blade specialist to the exact technical standards, dimensions, and performance specifications of the original machine's brand. This ensures a perfect fit and optimal cutting performance for your equipment.

An OEM machine blade isn't just a replacement part; it's a guarantee of quality that matches your machine's original design. But this raises an important question for many factory managers and purchasing agents: are they always the best choice, especially when cheaper alternatives exist? Let's dive deeper and explore the real value of OEM blades to help you make the best decision for your business.

OEM Industrial Blades Vs. Third-Party Compatibles: A Safe Bet Or A Cost Trap?

Tempted by the low price of third-party blades2? Be careful. Hidden costs from poor performance, machine wear, and frequent downtime can turn that "deal" into a costly trap.

While third-party blades have a lower initial price, OEM blades almost always provide a lower Total Cost of Ownership (TCO)3. This is because their superior quality ensures higher performance, longer lifespan, and reduced machine wear, preventing expensive downtime and protecting your equipment investment.

In my experience, the choice between OEM and third-party blades often comes down to short-term savings versus long-term value. I remember a client, a large packaging company in Mexico, who switched to cheaper compatible blades for their sealing and cutting machines. They called me a few months later. Their production line was suffering from inconsistent cuts and frequent jams. The initial savings were completely wiped out by increased waste and maintenance costs. We supplied them with our OEM blades, manufactured to the original machine's specifications, and their production efficiency returned to normal almost immediately. This is a classic example of why looking at the bigger picture is so important. A good OEM supplier provides more than just a blade; they provide reliability.

To help you compare, here's a breakdown of the key differences:

| Feature | OEM Blade | Third-Party Compatible Blade |

|---|---|---|

| Performance | Optimized for the specific machine, ensuring top speed and precision. | Variable; often fails to meet the machine's full potential. |

| Consistency | High; every blade is made to the same strict standards. | Low; quality can vary greatly between batches. |

| Machine Wear | Minimal; designed to work in harmony with the equipment. | Higher risk of causing premature wear on machine parts. |

| Lifespan | Longer due to superior materials and precision manufacturing. | Shorter; requires more frequent changes and replacements. |

| Total Cost | Higher initial price, but lower long-term cost (TCO). | Low initial price, but higher long-term cost. |

In Which Scenarios Are OEM Industrial Blades An Irreplaceable Choice?

Do you really need a premium OEM blade for every single task? Using the wrong blade in a critical, high-demand application can lead to serious production failures and safety risks.

OEM blades are irreplaceable in high-speed, high-precision, and continuous production environments. This includes industries like flexible packaging, paper converting, metal shearing, and food processing, where cutting accuracy, consistency, and blade reliability are absolutely critical for operational success and safety.

While a generic blade might work for a simple, low-demand task, it's a huge risk in more demanding situations. We know from experience that in certain scenarios, there is no substitute for an OEM-quality blade. Cutting corners here doesn't just reduce quality; it can damage expensive machinery, create unsafe working conditions, and bring your entire operation to a halt. You wouldn't put cheap tires on a high-performance race car, and the same logic applies to industrial blades. The blade is the part of your machine that does the real work.

Here are a few specific scenarios where I would never recommend anything less than an OEM blade:

High-Speed Converting And Slitting

In the paper and film industries, slitting machines run at incredible speeds. A blade that isn't perfectly balanced or lacks the correct sharpness angle can cause material tearing, vibrations, and uneven rolls. An OEM blade is manufactured with tight tolerances to ensure it runs true, providing a clean, consistent cut pass after pass.

Hygienic Food Processing

For food applications, like slicing meat or dicing vegetables, the blade material is as important as its sharpness. OEM blades for the food industry are made from specific grades of stainless steel that meet strict food-safety standards. They are designed for clean cuts that minimize cell damage and are easy to sanitize, preventing contamination.

Heavy-Duty Metal Shearing

Shearing thick metal plates requires blades that can withstand immense force and shock. OEM shear blades are made from specialized tool steels and heat-treated to a specific hardness. Using a subpar blade here can lead to it chipping or shattering, which is a major safety hazard and can cause catastrophic damage to the shear press.

When Choosing An OEM Supplier, What Should We Consider Besides Quality?

You've found a supplier who promises great blade quality. But what about their technical support, supply chain reliability, or ability to innovate? Ignoring these factors can lead to major problems later.

Beyond quality, you must consider a supplier's R&D capabilities for customization, their supply chain stability for reliable delivery, and their commitment to long-term technical support. A true OEM partner works with you to improve your process, not just sell you a part.

Finding the right manufacturing partner is about more than just the product itself. When you are looking for an OEM supplier, I recommend you look for these same qualities.

Here are the key factors you should evaluate:

Research & Development (R&D) Capability

Can the supplier help you solve a unique cutting problem? A strong OEM partner has an engineering team that can analyze your needs and recommend improvements. This could involve developing a custom blade geometry, testing new wear-resistant coatings, or suggesting a different material to extend blade life.

Supply Chain Stability

A great blade is useless if you can't get it when you need it. Ask about the supplier's production capacity, lead times, and international logistics capabilities. A reliable partner will have a robust supply chain to ensure you get consistent, on-time deliveries, preventing stockouts and production delays.

Technical Support and Partnership

What happens after the sale? A true partner provides ongoing technical support. They should be available to help you troubleshoot issues, optimize cutting parameters, and plan for future needs. Look for a supplier who wants to build a relationship and understands your business, not just your order number.

Conclusion

In summary, OEM industrial blades are essential for guaranteeing performance and reliability. Choosing the right OEM partner ensures you receive not just quality blades, but also innovation and dedicated support.