Is excessive heat damaging your blades and workpieces? This silent killer in machining can cause major issues. Understanding and controlling it is the key to better results.

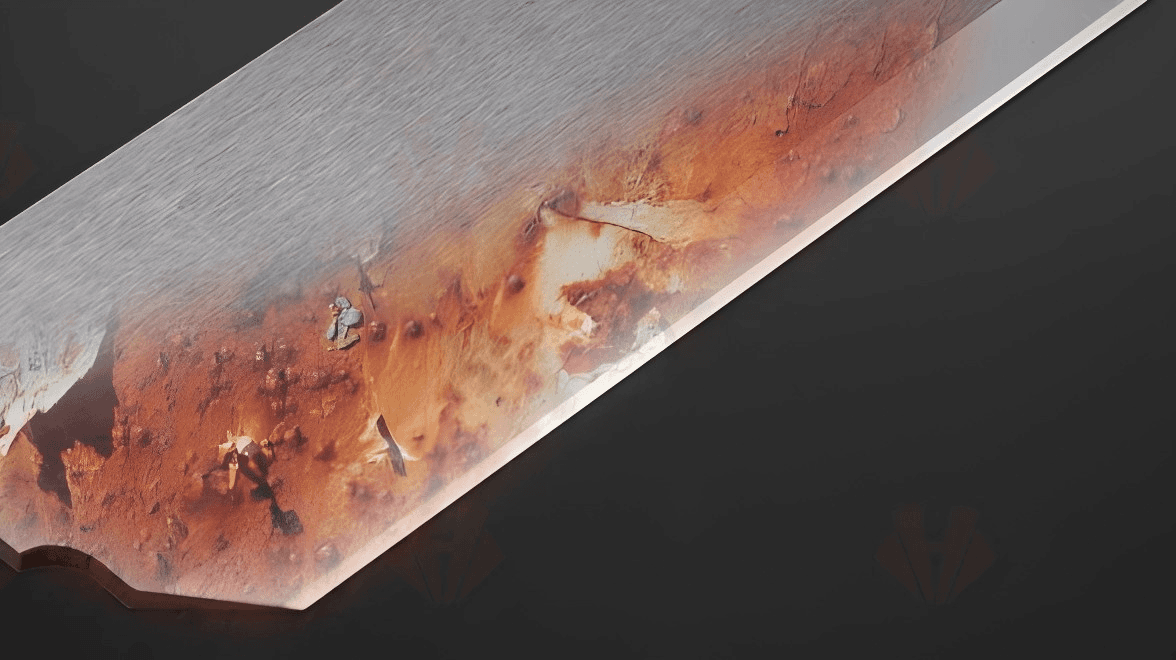

Cutting temperature1 is the heat generated in the cutting zone. It comes from the intense friction and material deformation between the blade, workpiece, and chip. Managing this heat is absolutely essential for high-quality, efficient machining and preventing premature blade failure.

It's a common problem, but thankfully, it's one we can solve. Let's dig deeper into where this heat comes from and what we can do about it. You need to understand the source of the problem before you can fix it.

Where Does Cutting Heat Originate?

Wondering why your cutting zone gets so hot? It’s not just one thing, but a combination of forces at play. Let’s break down the exact sources of this heat.

Cutting heat2 mainly comes from three areas. First, the energy used to deform the material into a chip. Second, friction between the moving chip and the blade's top surface. Third, friction between the newly cut workpiece and the blade's side.

Understanding the sources of cutting heat is the first step toward controlling it. Heat isn't just a byproduct; it's generated by intense physical processes. I often explain to my clients that it's like a three-front battle. We have to manage heat from all sides to protect the blade and the final product. For example, a client cutting thick titanium sheets saw their blades fail quickly. The main culprit was the immense energy needed to deform such a tough material, generating a huge amount of heat right at the cutting edge.

The Three Primary Heat Sources

The heat in the cutting zone can be broken down into these core areas:

| Heat Source | Description | Percentage of Total Heat (Approx.) |

|---|---|---|

| Plastic Deformation | The primary source of heat. This is the energy spent shearing the workpiece material to form a chip. | 60-70% |

| Chip-Blade Friction | Heat generated as the newly formed chip slides across the blade's rake face under high pressure and speed. | 20-30% |

| Blade-Workpiece Friction | Heat generated by friction between the blade's flank face and the newly machined surface of the workpiece. | 5-10% |

Recognizing which source is dominant in your specific application is crucial for choosing the right solution.

Why Is Cutting Temperature So Critical?

Is blade wear costing you too much? Uncontrolled cutting temperatures might be the hidden cause, quietly destroying your blades and compromising quality. Let's see why it's so important.

Cutting temperature1 is critical because it directly impacts everything. It drastically shortens blade life by accelerating wear and causing chemical reactions. It also harms machining quality by affecting dimensional accuracy and surface finish, and can even change the properties of the material you are cutting.

The effects of high cutting temperature are far-reaching. I worked with a client, who runs an automotive parts factory in Italy. He was struggling with inconsistencies when cutting high-strength steel components. His blades were wearing out unpredictably, and the dimensions of the finished parts were slightly off. After investigating, we found that high temperatures were softening the blade's cutting edge, leading to rapid wear. This also caused thermal expansion in the workpiece, which resulted in the dimensional inaccuracies after it cooled down. By focusing on temperature, we not only saved his blades but also improved the consistency of his final product.

Key Impacts Of High Cutting Temperature

High temperatures can cause a chain reaction of problems that affect your entire operation.

| Impact Area | Specific Problem | Description |

|---|---|---|

| Blade Life | Accelerated Wear | High heat softens the blade material, making it wear down much faster. |

| Oxidation | The blade material can react with air at high temperatures, creating a brittle oxide layer. | |

| Built-Up Edge (BUE) | Bits of the workpiece can weld onto the blade tip, ruining the surface finish. | |

| Machining Quality | Dimensional Inaccuracy | The workpiece expands when hot and shrinks when cool, leading to incorrect final dimensions. |

| Poor Surface Finish | BUE formation and blade wear lead to rough, uneven surfaces. | |

| Material Damage | Excessive heat can alter the microstructure and hardness of the workpiece material near the cut. |

How Can You Control Cutting Temperature?

Are you fighting a losing battle against heat? It can feel overwhelming, but you have more control than you think. Simple, effective methods can dramatically lower cutting temperatures.

The most effective ways to control cutting temperature are by optimizing your cutting parameters and using proper cooling methods. Adjusting cutting speed, feed rate, and depth of cut has a direct impact. Additionally, applying cutting fluids or coolants removes heat and reduces friction.

Controlling temperature is about finding the right balance. There is no single magic setting. It’s about adjusting the key variables for your specific material and application. Going back to my client, we didn't just sell him a new blade. We analyzed his entire process. We found his cutting speed was too high for the material, generating excessive heat. We recommended reducing the speed slightly and increasing the feed rate. This maintained his production rate while significantly lowering the temperature. We also helped him select a more effective coolant3 with better lubricating properties to further reduce friction. These small changes made a huge difference.

Methods For Temperature Control

Here is a breakdown of how you can actively manage heat in your cutting operations.

| Control Method | Parameter | Effect on Temperature |

|---|---|---|

| Cutting Parameters | Cutting Speed | Has the largest impact. Increasing speed significantly increases temperature. |

| Feed Rate | Increasing feed rate can slightly increase or decrease temperature, depending on the situation. | |

| Depth of Cut | A larger depth of cut generally increases the total heat generated. | |

| External Cooling | Cutting Fluids | Acts as a coolant to carry heat away and as a lubricant to reduce friction. |

| Air Cooling | Can be effective for certain materials and operations to dissipate heat. |

Finding the sweet spot for these parameters is key to protecting your blades and ensuring quality.

Conclusion

Cutting temperature1 is a critical factor in any machining process. By understanding its sources, impacts, and control methods, you can improve blade life, product quality, and overall efficiency.

Explore this link to understand cutting temperature and its significance in machining processes. ↩

Learn about the effects of cutting heat on machining efficiency and blade longevity. ↩

Explore this resource to discover effective coolant options that enhance machining efficiency and blade longevity. ↩