Tired of constant production stops? Frequent blade changes are costly and frustrating. Good edge retention is the solution you need for smoother operations and higher output.

Edge retention is an industrial blade's ability to stay sharp during prolonged cutting operations. Better retention means the blade resists becoming dull, ensuring consistent performance.

Edge retention is more than just initial sharpness. It's about endurance. Let's explore why this quality is so crucial for your success and how you can achieve it.

Why Is Edge Retention So Important?

Are production delays eating into your profits? A dull blade forces frequent stops. Superior edge retention keeps your machines running and boosts your bottom line.

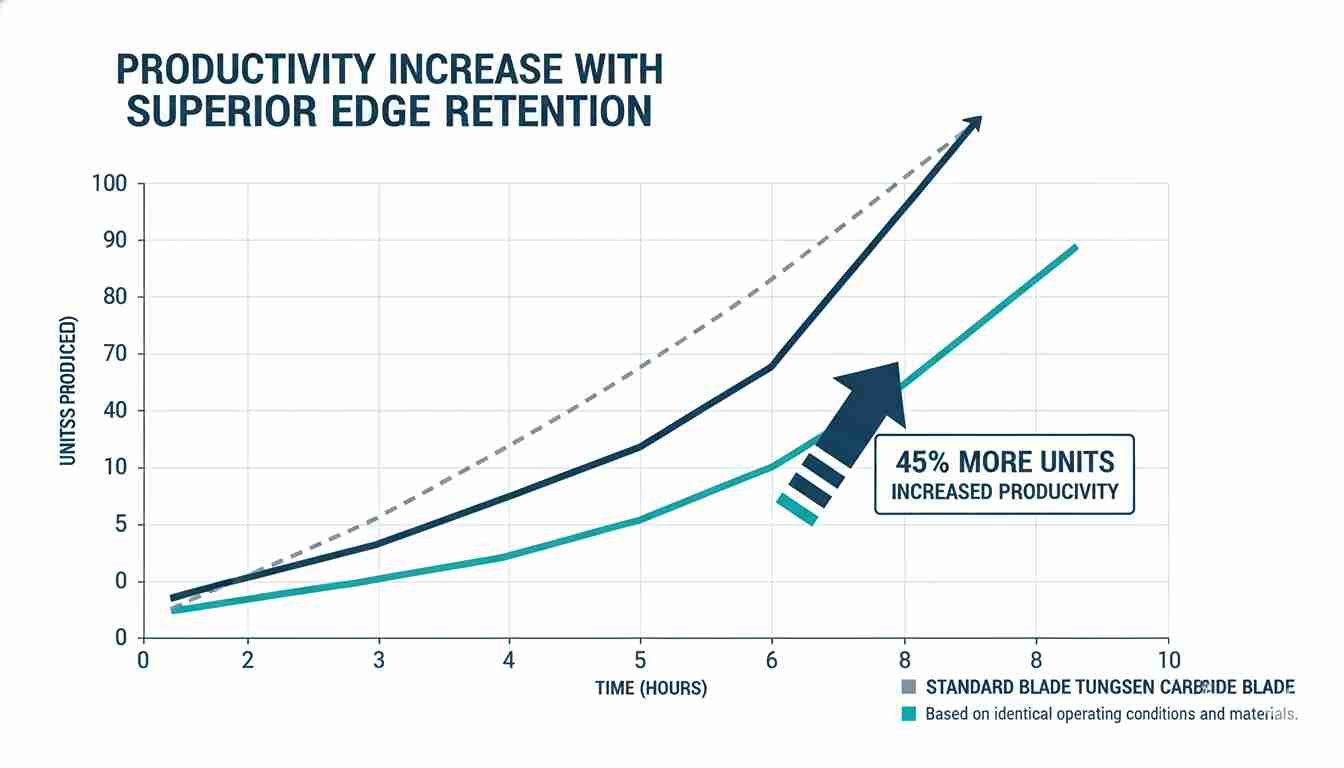

Great edge retention directly translates to higher productivity. It minimizes machine downtime for blade changes, reduces material waste from poor cuts, and lowers overall operational costs, making your production process more efficient.

I remember a client, who runs a packaging company in Germany. His corrugated board cutting line was stopping every four hours just to change blades. This constant downtime was a massive drain on their resources and productivity. We analyzed his situation and switched him to our custom-coated blades with enhanced edge retention. The result was immediate and impressive. They could now run a full 24-hour shift without a single blade change. This wasn't just about convenience; it had a huge financial impact.

The Real-World Impact

Better edge retention means you use fewer blades over time. This saves money on direct replacement costs. More importantly, it dramatically increases machine uptime. For my client's company, this meant thousands of extra boxes produced each day. It also ensures consistent cut quality, which reduces product rejects and material waste. It’s a simple change with a massive ripple effect on profitability.

| Metric | Before PASSION Blades | After PASSION Blades |

|---|---|---|

| Blade Lifespan | 4 hours | 24 hours |

| Daily Downtime | 90 minutes | 15 minutes |

| Blade Cost/Month | €1,200 | €400 |

| Productivity Gain | Baseline | +15% |

What Is The Difference Between Toughness And Edge Retention?

Confused by blade specifications? Choosing between toughness and edge retention can be tricky. Understanding the difference is key to preventing chipped or dull blades and optimizing performance.

Edge retention is a blade’s ability to resist abrasive wear and stay sharp. Toughness, on the other hand, is its ability to resist chipping or breaking when it hits something hard.

Many customers I speak with think hardness is all that matters. But there is a delicate balance. Think of it like this: edge retention comes from a material's hardness and wear resistance. It fights the slow, grinding wear from friction during cutting. Toughness is about impact resistance1. It prevents the blade from fracturing when it hits a staple in a cardboard box or a hard impurity in plastic. A blade can be very tough but not hold an edge for long. Another blade can hold an edge for a very long time but shatter on the first impact.

Finding The Right Balance

The ideal blade has a good mix of both qualities, but this often involves a trade-off. A harder material typically has better edge retention but might be more brittle and less tough. A tougher material may bend or deform rather than chip, but it will likely dull faster. The right choice depends entirely on your application. For clean, continuous cutting of soft materials, you should prioritize edge retention. For cutting materials with potential impacts, toughness becomes more critical.

| Feature | Edge Retention | Toughness |

|---|---|---|

| Primary Goal | Stay sharp | Resist chipping/breaking |

| Resists | Abrasive wear | Sudden impact/shock |

| Related To | Hardness, Wear Resistance | Ductility, Impact Strength |

| Failure Mode | Becomes dull | Chips, fractures, or breaks |

What Factors Affect Edge Retention?

Are your blades dulling too quickly? You might be overlooking key factors beyond just the steel type. Understanding these elements can dramatically extend your blade's life and performance.

Four main factors influence edge retention: the blade material's hardness and wear resistance, the quality of the heat treatment process2, the application of specialized coatings, and the precision of the blade's edge geometry.

It is not just about using good steel. It is about optimizing every single variable to create a superior blade that lasts. Let's break down these four pillars of performance. Each one plays a critical role in how long and how well a blade will cut. A flaw in any one of these areas can compromise the final product. This leads to premature failure and costly downtime for our clients. That’s why we control every step of our manufacturing process.

The Four Pillars of Blade Performance

We start with the best raw material, then perfect it through expert treatment and design. A mistake at any stage can weaken the final blade.

| Factor | Description | How It Improves Retention |

|---|---|---|

| Material & Hardness | The base alloy, like Tungsten Carbide or Powder HSS. | Harder materials with fine grain structures resist wear much better. |

| Heat Treatment | Controlled heating and cooling (quenching/tempering). | Creates a stable microstructure that won't deform or chip easily under stress. |

| Coatings | Micro-thin layers like TiN, TiAlN, or DLC. | Reduce friction and heat, protecting the underlying edge from wear. |

| Edge Geometry | The angle and finish of the cutting edge. | A precise, smooth edge reduces cutting force, which minimizes stress and slows down wear. |

How Does Edge Retention Affect Different Industries?

Do you think all cutting jobs are the same? The demand for good edge retention varies wildly between industries. Using the wrong blade for your specific job means wasted money and inefficient production.

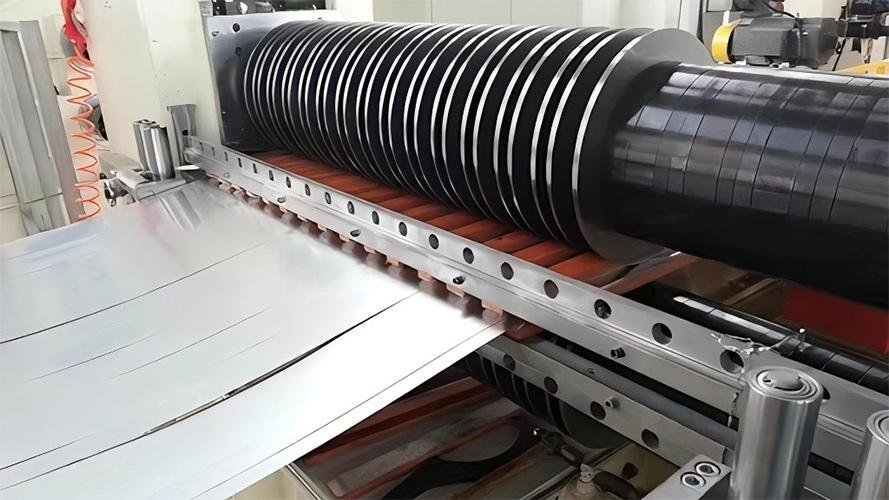

Different industries have unique needs. In food processing, edge retention ensures clean cuts and hygiene. In textiles, it prevents fraying. For metals, it maintains precision and reduces tool changes during heavy-duty operations.

I have learned that a one-size-fits-all approach to blades never works. Each industry places a different kind of stress on the blade's edge. This requires a unique balance of properties for the blade. A blade that excels at slicing paper might fail spectacularly when cutting fiberglass. For example, a client in the food processing industry cutting frozen fish needed a blade that stayed extremely sharp to avoid shredding the product. Here, better edge retention meant better product quality and less waste.

Industry-Specific Requirements

In contrast, a client in metal recycling needed a blade that could handle occasional impacts from foreign objects. So, toughness was a key consideration alongside retention. We helped both clients by customizing the blade material and edge geometry for their specific needs. Understanding these small differences is the key to achieving optimal performance.

| Industry | Primary Challenge | Why Edge Retention Matters |

|---|---|---|

| Food Processing | Soft, sticky, or frozen materials | Ensures clean cuts, maintains hygiene, prevents product damage. |

| Packaging | Abrasive materials like cardboard | Minimizes paper dust, ensures clean folds, reduces downtime on fast lines. |

| Textiles/Fibers | Tough, synthetic fibers | Prevents fraying and pulling of fabric, ensures precise patterns. |

| Plastics/Rubber | Heat-sensitive materials | Reduces melting at the cut edge, ensures a smooth finish, and avoids burrs. |

What Is The Best Material For Maximum Edge Retention?

Are you struggling to find a blade that lasts? The material you choose is the foundation of performance. Selecting the right one is the first step to unlocking long-lasting sharpness.

For ultimate edge retention, Tungsten Carbide and Powder Metallurgy3 (PM) steels are top choices. Their incredibly hard microstructures and high wear resistance allow them to hold a sharp edge far longer than conventional steels.

I often get asked, "What's the absolute best material?" The simple answer is, it depends on what you are cutting and your budget. However, when the main goal is maximizing uptime through superior edge retention, some materials clearly stand out from the rest. Standard steels like D2 or M2 offer a good baseline of performance. But for demanding applications, they can dull relatively quickly. This is where advanced materials come in to solve the problem.

A Hierarchy Of Performance

We recommend Powder Metallurgy (PM) high-speed steels for a significant upgrade. The PM manufacturing process creates a very fine and uniform grain structure. This boosts both wear resistance and toughness. But for the most abrasive and high-volume cutting tasks, nothing beats solid Tungsten Carbide. It is dense, exceptionally hard, and holds an edge like nothing else. It can often outperform even the best steels by a factor of 5 to 10.

| Material | Key Advantage | Best Use Case |

|---|---|---|

| Standard HSS (e.g., M2) | Cost-effective, good all-rounder | General purpose cutting, less abrasive materials. |

| PM High-Speed Steel | Excellent wear resistance & toughness | High-volume cutting of abrasive papers or plastics. |

| Tungsten Carbide | Supreme hardness & wear resistance | Extreme-volume cutting of fiberglass, composites, and metals. |

Conclusion

In summary, superior edge retention is key to production efficiency. By choosing the right material, heat treatment, and geometry, you can reduce downtime and boost your bottom line with every cut.