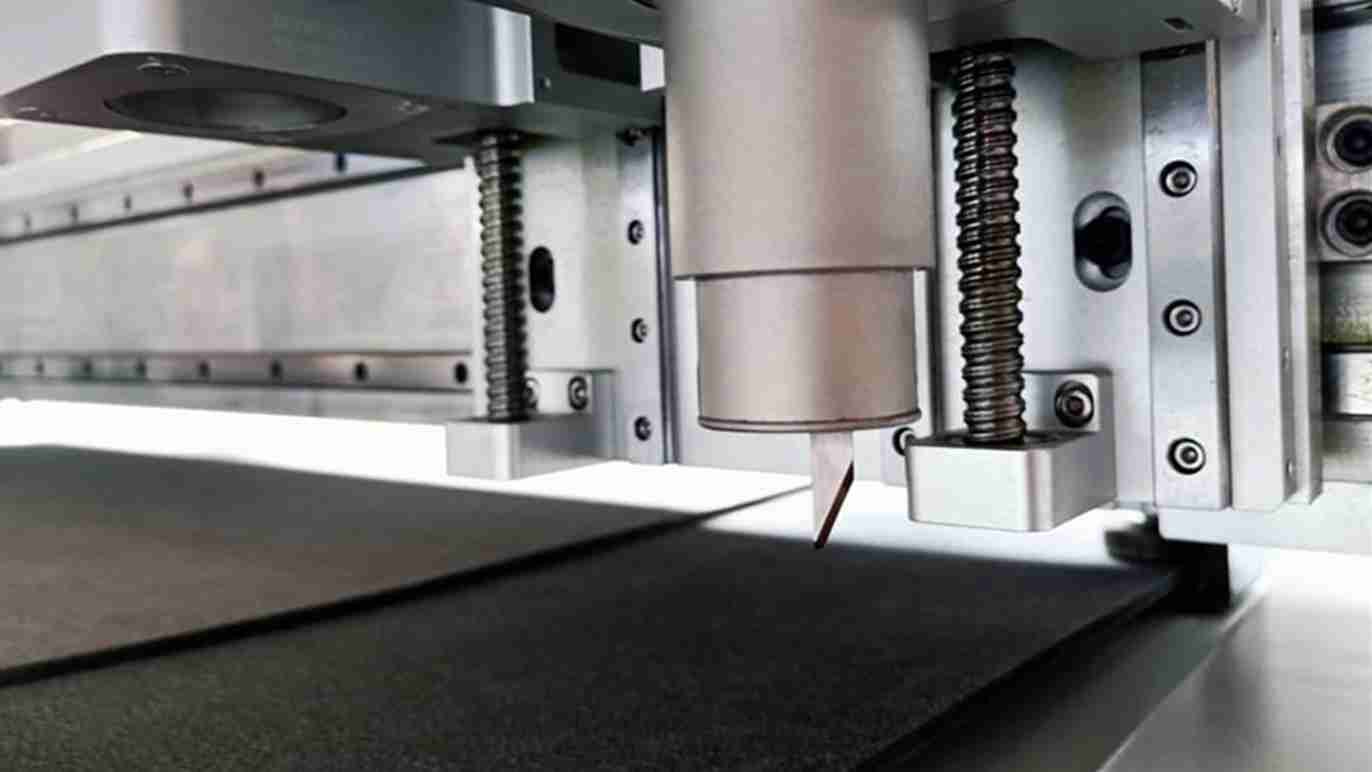

Struggling with inconsistent cuts across different materials? The wrong settings can ruin stock and hurt efficiency. Understanding your CNC blade's amplitude and frequency1 is key to achieving perfect results.

A CNC oscillating blade2’s amplitude typically ranges from 1mm to 10mm, while its frequency can exceed 20,000 cycles per minute (around 333Hz). These settings hinge on the tool type: pneumatic for power and thick materials, or electric for precision and flexible materials.

But what do these numbers actually mean for your production line? It's all about matching the blade's movement to your specific material. Getting this right is the difference between a rough, wasteful cut and a clean, profitable one. Let's explore how to fine-tune these settings to master your cutting process.

How Does Amplitude Affect Cutting Quality?

Have you ever made a cut that wasn't clean or even damaged the material? This happens when the blade’s movement is mismatched. Adjusting the amplitude correctly is vital for flawless cuts.

Amplitude is the blade's vertical travel distance. Too little amplitude causes incomplete cuts, while too much can damage the material or reduce precision. The right amplitude ensures a clean, thorough cut without harming the material's integrity or wasting your valuable time.

I want you to think about it like erasing a mistake on paper. The amplitude is the distance you move the eraser back and forth. If you only move it a tiny bit, you will leave parts of the mark behind. This is like an incomplete cut because the amplitude was too small. Now, imagine you move the eraser too far. You might accidentally erase the correct words next to the mistake or even tear the paper. This is what happens when the amplitude is too large. It can damage the surrounding material or lower the overall cutting accuracy. The goal is to find that perfect balance where the blade moves just enough to cut through the material cleanly and efficiently.

The Right Amplitude For The Job

Choosing the correct amplitude is not a one-size-fits-all solution. It depends entirely on the material's thickness and density.

| Material Type | Recommended Amplitude | Reason |

|---|---|---|

| Thin & Soft (e.g., films, thin leather) | Small (e.g., 1-2mm) | Prevents tearing and ensures high precision. |

| Medium (e.g., EVA foam, cardboard) | Medium (e.g., 3-5mm) | Balances cutting depth with a clean edge. |

| Thick & Dense (e.g., rubber, honeycomb) | Large (e.g., 8-10mm) | Provides the necessary power to cut through. |

What Are The Key Differences Between Pneumatic And Electric Oscillating Tools?

Choosing between pneumatic and electric oscillating tools3 can feel confusing. Making the wrong choice can lead to poor cutting performance and lower efficiency. Knowing their core differences helps you select the perfect tool.

Pneumatic tools use compressed air for high power and large amplitude (8–10mm), making them ideal for thick materials. Electric tools use a motor for high frequency (up to ~333Hz) and smaller amplitude (1–3mm), offering greater precision for flexible materials.

I get this question all the time from clients. They ask, "Lyn, should I get a pneumatic or an electric tool?" My answer is always the same: it depends entirely on the job you need to do. A pneumatic tool is a real workhorse. It relies on compressed air to deliver powerful, forceful strokes. This makes it perfect for tough, thick materials that need a lot of force to cut through. On the other hand, an electric tool is all about speed and finesse. It's driven by a high-frequency motor, which allows for incredibly fast and precise vibrations. This is ideal for materials where a smooth, clean edge is more important than raw power.

Tool Comparison

Each tool has its place in the workshop. The key is understanding their strengths to maximize your machine's potential.

| Feature | Pneumatic Oscillating Tool | Electric Oscillating Tool |

|---|---|---|

| Power Source | Compressed Air | Electric Motor |

| Amplitude | Large (Approx. 8–10mm) | Small (Approx. 1–3mm) |

| Frequency | Lower (Approx. 167Hz) | Higher (Over 333Hz) |

| Best For | Power and depth | Speed and precision |

Which Tool Should You Choose For Your Material?

Are you unsure which oscillating tool is right for your material? Using the wrong one wastes time and money on bad cuts. Let’s match the right tool to your application for optimal results.

Choose a pneumatic tool for thick, dense materials like industrial gaskets, composite rubber, and automotive interiors. Opt for an electric tool for thin, flexible materials requiring speed and precision, such as textiles, packaging board, foam, and advertising displays.

Let me share a quick story. I was working with a client, Javier from Mexico, who runs a company making custom packaging. He was cutting a lot of honeycomb board4 but struggled with rough, frayed edges. His machine was equipped with a standard electric oscillating tool. While great for thinner cardboard, it just didn't have the "punch" for the thick honeycomb. The small amplitude wasn't clearing the material effectively on each stroke. We recommended he switch to one of our pneumatic oscillating tools. The larger 8mm amplitude and powerful impact immediately solved his problem. His cuts became clean, his production speed went up, and material waste went down. It was a simple switch that made a huge difference to his bottom line.

Material And Tool Matching Guide

This simple guide can help you make the right choice for your most common applications.

| Material | Recommended Tool | Reason |

|---|---|---|

| Leather & Textiles | Electric | Requires high speed and precision for clean, non-fraying edges. |

| EVA Foam | Electric | Fine control and speed produce smooth cuts in soft materials. |

| Composite Rubber | Pneumatic | Needs high impact force and depth to cut through dense material. |

| Honeycomb Board | Pneumatic | Large amplitude cleanly slices through the internal structure. |

| Industrial Gaskets | Pneumatic | Power is essential for cutting thick, tough gasket materials. |

Conclusion

Choosing the right amplitude, frequency, and tool is crucial. At PASSION, we help you find the perfect cutting solution for unmatched precision and efficiency on every project.

Learn how these settings impact your cutting results and efficiency. ↩

Explore this link to understand the mechanics and benefits of CNC oscillating blades for your projects. ↩

Learn about various oscillating tools and how to choose the right one for your needs. ↩

Discover techniques and tools for achieving clean cuts on honeycomb board. ↩