Industrial blades wearing out too fast costs time and money. The cause is often a misunderstanding of blade edges. The right edge design boosts both efficiency and your bottom line.

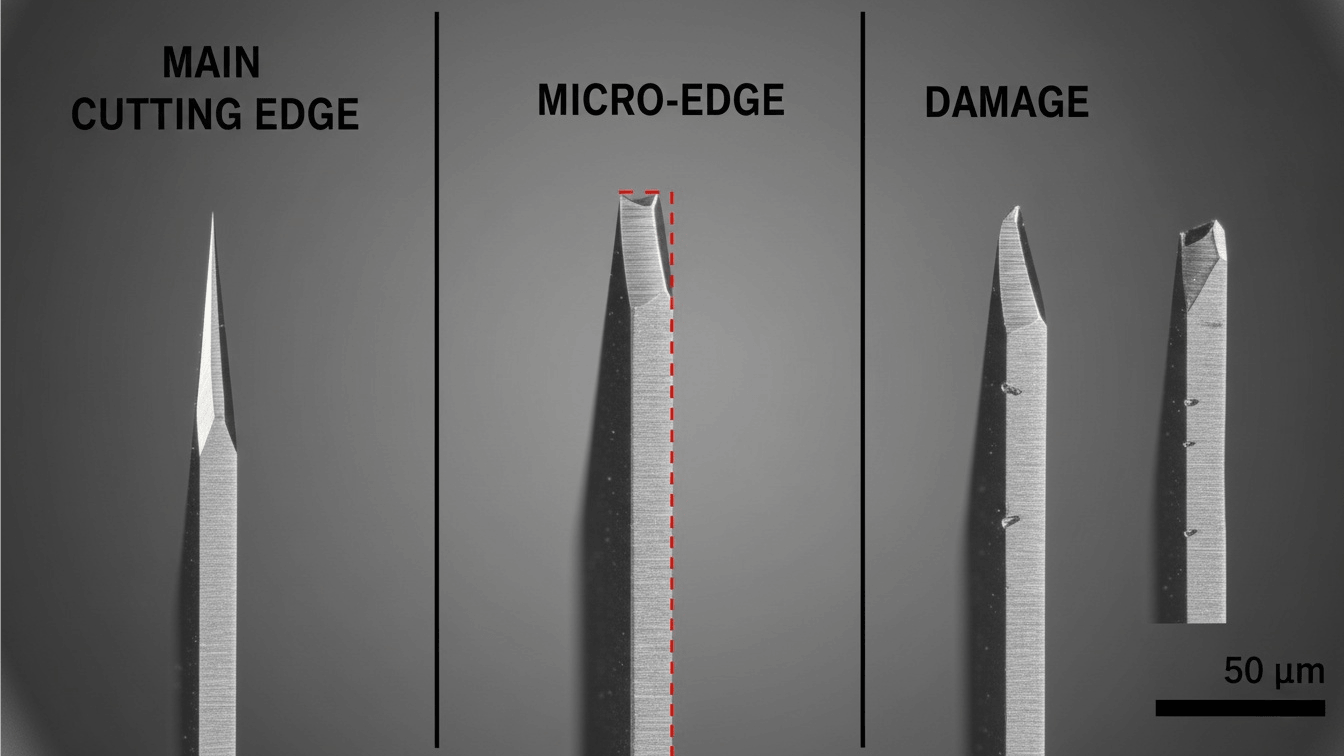

The main cutting edge handles the bulk of material removal and defines cutting performance. A micro-edge is a microscopic, specially prepared area on that main edge that strengthens it, preventing chipping and significantly extending the blade's life. It adds durability where it matters most.

I often use a simple analogy to explain this. Think of a sharpened pencil. The long wooden cone is the main cutting edge; it defines how easily the pencil moves through paper. The tiny graphite point that actually writes is the micro-edge. It takes all the pressure. A small change there makes a big difference in how it performs and how long it lasts. Understanding this distinction is key to optimizing your cutting process. Let's explore this further to see how it applies to your operations.

How Does The Main Cutting Edge Influence Overall Performance?

Your cuts are rough, and material waste is high. Poor chip flow causes jams and downtime. The geometry of your blade’s main cutting edge is likely the problem.

The main cutting edge's geometry—like its rake and clearance angles—directly controls cutting efficiency, the quality of the cut surface, and how well chips are evacuated. Getting these angles right for your material means smoother operations and better products.

The main cutting edge is the workhorse of your blade. Its shape does most of the heavy lifting. Three key angles determine its behavior: rake angle1, clearance angle2, and edge inclination angle3. Each one has a specific job. For example, a client of mine, who manages a large packaging facility in Germany, was struggling with a lot of dust and frayed edges when cutting thick cardboard. Their blades were sharp, but the cuts weren't clean. The problem was the main cutting edge geometry. Their existing blades had a clearance angle that was too small. This caused friction and tore the material instead of slicing it cleanly.

Key Angles Of the Main Cutting Edge

We worked with them to develop a custom blade with a slightly increased clearance angle. This small adjustment reduced the contact area behind the cut, immediately resulting in cleaner edges and less dust. It also lowered the cutting force needed, which reduced wear on their machines.

| Angle Type | Primary Function | Impact of Incorrect Angle |

|---|---|---|

| Rake Angle | Controls chip formation and flow | Poor chip evacuation, increased cutting force |

| Clearance Angle | Reduces friction behind the cut | High friction, material tearing, overheating |

| Edge Inclination | Directs chip flow away from the workpiece | Chips jamming, poor surface finish |

This shows that the "sharpness" of a blade is much more complex than just a fine point. The macro-geometry of the main cutting edge must be perfectly matched to your application for optimal results.

Why Is A Micro-Edge The Secret To Blade Longevity?

Are you changing blades constantly? Chipping and micro-fractures are killing your uptime and budget. A perfectly sharp edge is often too fragile for industrial demands.

A micro-edge is a tiny, rounded or beveled transition on the cutting edge. This design reinforces the tip, distributing cutting stress more evenly. This prevents the micro-chipping that leads to blade failure, drastically increasing durability and usable life.

A perfectly sharp, razor-like edge seems ideal, but it has a major weakness: it is incredibly fragile. Under the immense pressure of industrial cutting, a sharp tip concentrates all the force onto a tiny point. This leads to micro-chipping, where small pieces break off. These small chips are the beginning of an early blade failure. This is where the micro-edge becomes so important. By creating a very small, controlled radius (usually between 3 and 30 micrometers) on the tip, we blunt it just enough to add significant strength. This is not about making the blade dull; it is about making it tough.

The Impact of A Micro-Edge

I remember working with a plastics recycling plant in Brazil. They were shredding bales of PET plastic, and the abrasive material was destroying their blades in hours. The edges were chipping constantly. We supplied them with blades featuring a 20µm micro-edge. The result was immediate. The micro-edge helped disperse the cutting forces, preventing micro-cracks from forming. As research from the journal Wear has shown, this can increase blade fatigue resistance and extend life by over 30%. For this client, their blade life more than doubled. This saved them a huge amount in replacement costs and downtime. The "secret" is moving from a fragile, sharp tip to a robust, engineered one.

When Should You Choose A Micro-Edge Over A Sharper Edge?

You chose the sharpest blade available, but it failed almost immediately. Your material might be too demanding. Choosing the right edge isn't always about maximum sharpness.

Choose a micro-edge when cutting hard, abrasive, or inconsistent materials like composites, certain plastics, or high-density textiles. Opt for a sharp edge for soft, clean materials like thin film or paper, where a smooth finish is the top priority.

The decision between a micro-edge and a sharp edge depends entirely on your application. There is no single "best" solution. You must balance durability against the need for a low-force, delicate cut. For tough jobs, a micro-edge is almost always the right choice. I worked with a textile company in Turkey that specializes in industrial fabrics. They were cutting an abrasive synthetic material for protective gear. The sharp blades they were using became dull and started chipping within the first hundred cuts. The material's toughness was simply too much for a fragile edge.

Application-Based Edge Selection

We switched them to a blade with a subtle micro-edge. The cutting force increased slightly, which was not a problem for their machines, but blade life increased dramatically. They went from changing blades multiple times a day to once every few days. The micro-edge provided the toughness needed for the abrasive fibers. On the other hand, if you are cutting delicate plastic film for food packaging, a sharp edge is better. It requires less pressure and reduces the risk of stretching the material.

| Application Requirement | Recommended Edge | Why? |

|---|---|---|

| Cutting hard/abrasive materials | Micro-Edge | Provides strength and prevents chipping. |

| Interrupted cuts (e.g., staples) | Micro-Edge | Resists impact damage. |

| Maximum finish quality on soft material | Sharp Edge | Slices cleanly with minimal force. |

| Cutting very thin, delicate film | Sharp Edge | Prevents material stretching or tearing. |

The key is to analyze your material and your cutting process. You should not just assume "sharper is better."

How Do We Precisely Control Micro-Edge And Main Edge Geometry?

Inconsistent blade performance is frustrating. One blade lasts a week, the next a day. This variation comes from poor manufacturing control, costing you reliability and trust in your supplier.

We use advanced CNC grinding machines and specialized processes like drag finishing or micro-blasting. This allows us to precisely shape the main cutting edge and apply a consistent micro-edge, ensuring every blade performs identically.

The benefits of a micro-edge are lost if it is not applied with absolute precision. An uneven micro-edge creates weak points that will chip and fail. We do not leave this to chance. We combine advanced CNC grinding for the main cutting edge geometry with specialized processes to create the perfect micro-edge. This ensures that every blade we ship is a perfect copy of the one before it. A food processing client in Australia came to us with a critical need for this kind of consistency.

Our Commitment To Precision

They were slicing frozen blocks of vegetables, an application that is both hard and requires extreme cleanliness. An inconsistent blade could chip, posing a contamination risk. It could also create a rough cut, affecting product quality. They needed blades that were durable and identically durable every time. Using our controlled processes, we delivered blades with a consistent 15µm micro-edge. We verify this using high-magnification optical comparators. This guaranteed them predictable performance, long blade life, and the safety assurance they needed.

| Process Step | Our Method | Benefit to You |

|---|---|---|

| Main Edge Grinding | Multi-axis CNC grinders | Perfect, consistent main angles for efficiency. |

| Micro-Edge Application | Drag finishing, brushing, or blasting | Uniform, controlled radius for maximum strength. |

| Quality Inspection | Digital optical measurement systems | Verification that every blade meets exact specs. |

This level of control means you can trust our blades to perform reliably, batch after batch. It removes one more variable from your production process.

Conclusion

Understanding the roles of the main cutting edge and micro-edge is crucial. Choosing the right combination for your material ensures optimal performance, longer blade life, and better profitability.