Choosing the wrong CNC knife1 wastes material and time. This leads to frayed edges, inaccurate cuts, and failed projects. Understanding the key differences ensures you make the perfect cut.

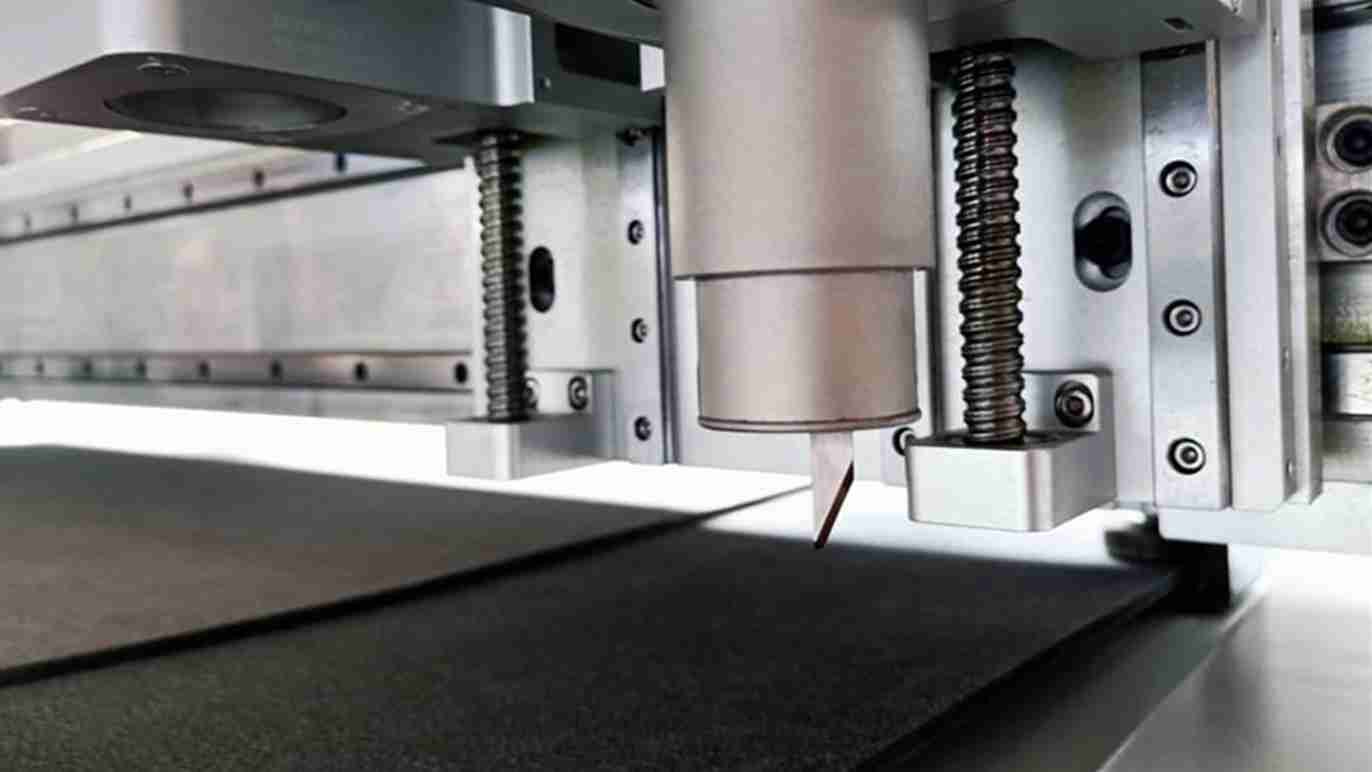

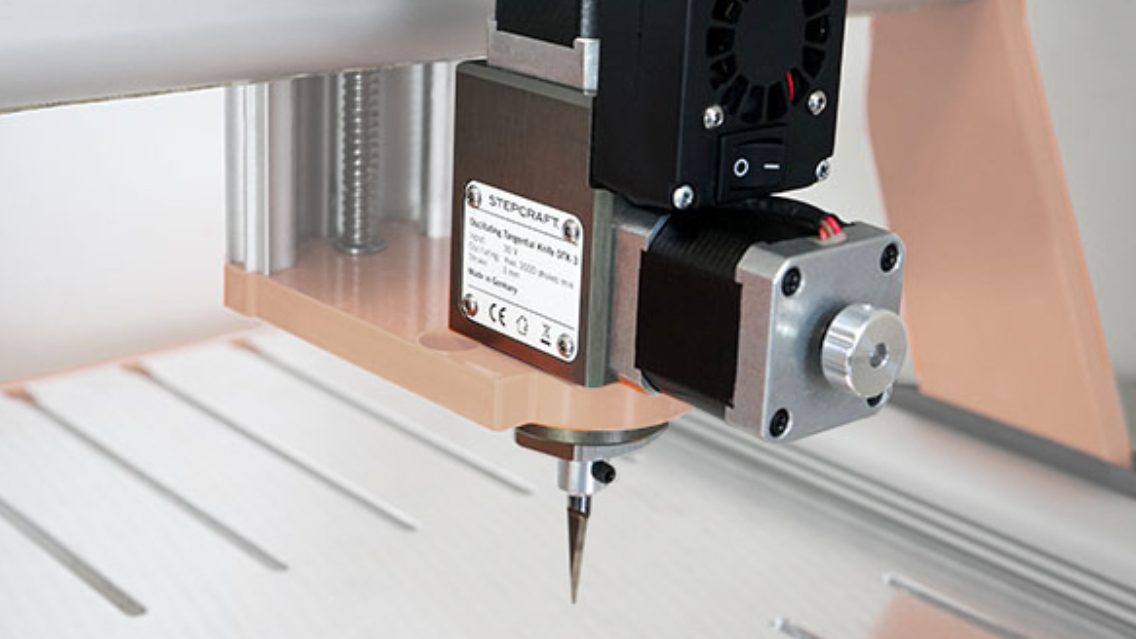

An oscillating knife2 uses high-speed vibrations3 to cut thick, dense materials cleanly. A drag knife4, in contrast, passively drags its blade to cut thin, soft materials, a simpler but less precise method that relies on machine movement.

Now you have a basic idea of the difference. But the details really matter when it comes to getting your specific job done right. The choice between these two tools can be the difference between a profitable production run and a pile of wasted material. Let's break down these differences further. This will help you choose the right tool with confidence every single time.

How Does The Cutting Mechanism Differ?

Your cuts are tearing or bunching up the material. You might blame the material, but the real issue is often the cutting action. Knowing the difference between dragging and vibrating can solve this.

A drag knife is passive. It relies on the machine's movement to pull the blade through the material. An oscillating knife is active. It uses a motor for high-speed, up-and-down punching motions to perform the cut.

A drag knife is the definition of simplicity. The blade holder is not powered. The CNC machine simply drags the sharp point of the knife along the designated cutting path. Think of it like using a utility knife to score a line on paper. The entire cutting force comes from the machine's movement, creating friction between the blade and the material. This is why a sharp blade is so critical for a drag knife. If the blade is dull, the friction increases dramatically, and it will start to pull or tear the material instead of slicing it cleanly.

An oscillating knife works in a completely different way. It’s an active cutting tool. A motor moves the blade up and down at an extremely high frequency, sometimes thousands of times per second. This turns the cut from a dragging motion into a series of tiny, rapid punches. This vibration drastically reduces friction. The blade slices through material with an "impact cutting" action, not by relying on blade sharpness alone.

I often explain it to clients with this analogy. A drag knife is like trying to cut a thick cake by just pushing a knife straight through it. An oscillating knife is like using a gentle sawing motion to slice through the cake cleanly.

Mechanism At A Glance

| Feature | Drag Knife | Oscillating Knife |

|---|---|---|

| Principle | Passive Friction Cutting | Active Vibrational Cutting |

| Force Source | Machine Movement (Dragging) | Internal Motor (Vibrating) |

| Action | Continuous Contact / Dragging | High-Frequency Up-Down Motion |

| Friction Level | High | Low |

Which CNC Knife Is Right For Your Materials?

You bought a powerful CNC machine but your cuts are still messy. Using the wrong knife damages expensive materials and can ruin your project. Matching the knife to the material guarantees flawless results.

Use a drag knife for thin, flexible materials like vinyl, paper, and thin films. Choose an oscillating knife for thick, dense, or tough materials like leather, rubber, foam, and honeycomb cardboard.

The simple, low-force nature of a drag knife makes it perfect for materials that don't resist much. It excels at cutting thin and soft sheets. This includes materials like adhesive vinyl for creating custom stickers, paper and cardstock for intricate crafts, and thin plastic films for stencils. We have many clients in the sign-making and craft industries who rely on drag knives for their daily work. It’s effective and very cost-efficient for these applications. However, if you try to use a drag knife on something like thick rubber, it will likely just stretch and deform the material, not cut it.

The oscillating knife is the heavy-duty specialist. Its powerful vibrational cutting action is designed to handle the tough stuff. This includes thick leather for upholstery, dense foam for custom inserts, honeycomb cardboard for protective packaging, and composite fibers for industrial parts. The vibration allows the blade to sink into the material and cut it cleanly without needing excessive downward pressure, which would otherwise crush or deform it.

I recently worked with a client from a packaging company in Germany. He was struggling to cut thick honeycomb cardboard for protective inserts. His drag knife was tearing the paper layers and crushing the honeycomb structure. We recommend switching to a vibrating knife system. The high-frequency cuts were clean and precise, preserving the cardboard's structural integrity. It completely eliminated his material waste and significantly improved his production speed. This is a perfect example of matching the tool to the material.

How Do They Compare In Cut Quality And Precision?

Your finished parts have frayed edges and don't fit together perfectly. This lack of precision can cost you clients and damage your reputation. Understanding how each knife impacts quality is key to professional results.

Oscillating knives generally produce superior cut quality. The vibrational cutting minimizes material stress, resulting in clean, smooth edges. Drag knives can cause tearing or rough edges, especially on thicker materials or with dull blades.

With a drag knife, cut quality is directly linked to friction and a principle called "caster angle." As the knife changes direction, especially in sharp corners, the blade tip has to pivot to follow the path. This can sometimes lead to slightly rounded corners or small imperfections. On soft materials, it might also pull and stretch the material slightly before it cuts, reducing overall precision. If the blade isn't perfectly sharp, the effect is much worse, leading to fuzzy or frayed edges that look unprofessional.

The oscillating knife, on the other hand, gives you much more control. Because the blade is constantly moving up and down, it reduces the lateral forces on the material. It doesn't pull or stretch it. This allows for incredibly sharp and accurate corners, even in thick and difficult materials. The resulting edge is almost always cleaner and smoother. A customer making rubber gaskets with a drag knife struggles with leaky seals because of slightly rounded corners. Switching to an oscillating knife creates a perfect 90-degree corner, solving the problem instantly. The superior quality is obvious.

Quality & Precision Breakdown

| Aspect | Drag Knife | Oscillating Knife |

|---|---|---|

| Edge Finish | Can be fuzzy or rough | Consistently clean and smooth |

| Corner Accuracy | Can be slightly rounded | Very sharp and precise |

| Material Stress | Higher (pulling/stretching) | Minimal (clean slicing) |

| Best For | Graphics, thin prototypes | Finished goods, gaskets, packaging |

What About The Cost And CNC Machine Requirements?

You're trying to choose a new CNC cutting tool but are worried about the budget. A bad investment can cripple your cash flow without delivering the results you need. Understanding the full cost picture helps you make a smart, profitable choice.

Drag knives and their holders are simple and have a very low initial cost. Oscillating knives are more complex, requiring a motor and specialized holder, making them a more significant upfront investment.

There is no contest when it comes to the initial purchase price. A drag knife tool holder is a simple piece of metal. The blades are small and relatively inexpensive. This makes it an extremely accessible technology for hobbyists, startups, or businesses with a very limited budget or a single, specific need for thin material cutting. Almost any CNC router can be fitted with a drag knife.

An oscillating knife system is a different story. The tool head contains a motor, bearings, and more complex mechanics, so the upfront cost is significantly higher. Your CNC machine also needs to be able to supply power to the tool head and control its functions. However, thinking only about the initial price can be a mistake. I always advise clients to think beyond the sticker price. We need to consider the long-term value.

The initial savings on a drag knife can be quickly lost through wasted material and rejected parts if it's the wrong tool for the job. The oscillating knife, while more expensive, often provides a much faster return on investment. It reduces waste, increases production speed, and most importantly, it opens up new business opportunities. Suddenly, you can bid on jobs cutting foam, rubber, and composites—markets that demand higher prices and offer better margins. The investment in an oscillating tool is often an investment in your company's growth.

Conclusion

Choosing between a drag and oscillating knife depends on your material, quality needs, and budget. Both are excellent tools when used for the right job, ensuring precision in every cut.

Understanding CNC knives is crucial for optimizing your cutting processes and improving project outcomes. ↩

Explore the advantages of oscillating knives to enhance your cutting efficiency and precision. ↩

Discover how high-speed vibrations can enhance cutting efficiency and reduce material waste. ↩

Learn the key differences to choose the right knife for your specific material and project needs. ↩