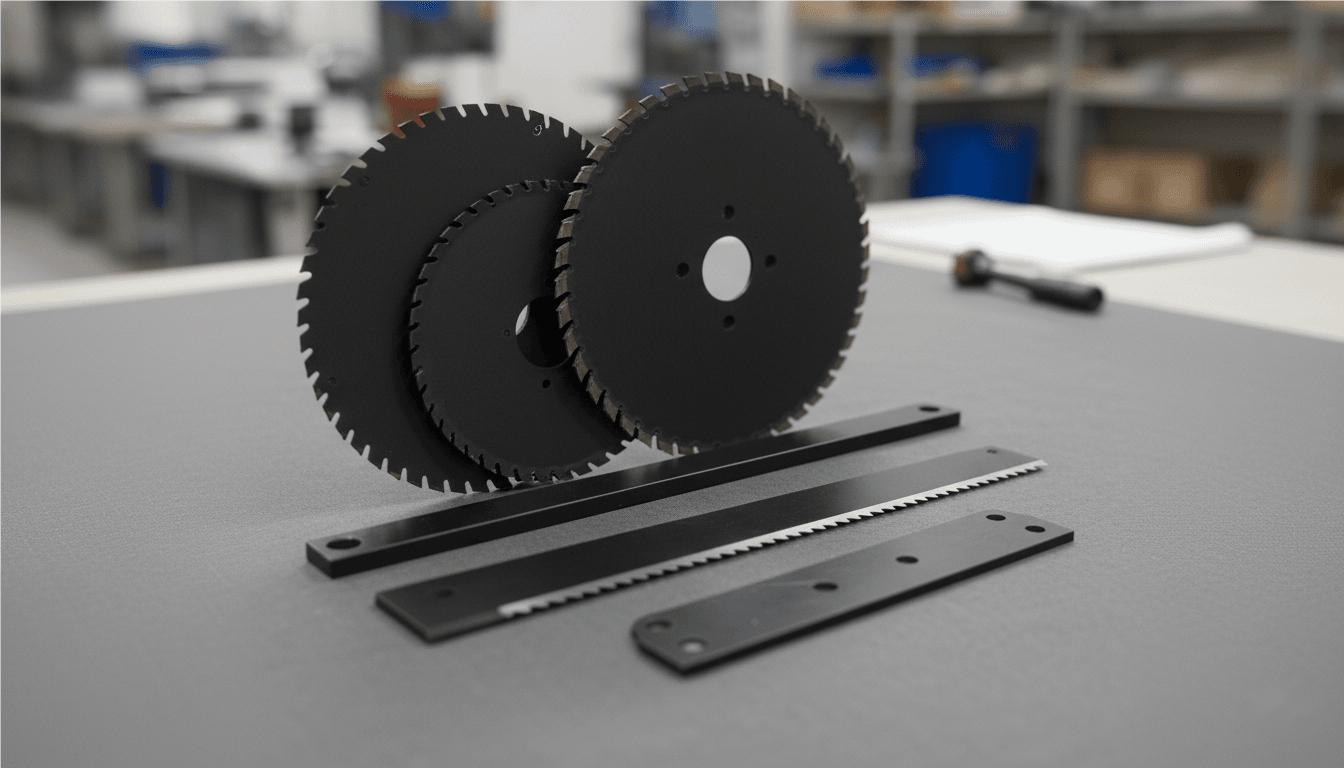

Choosing the wrong blade coating can cause rapid corrosion and costly downtime. This leads to production losses and frequent replacements. Understanding black oxidation helps you select the best protection.

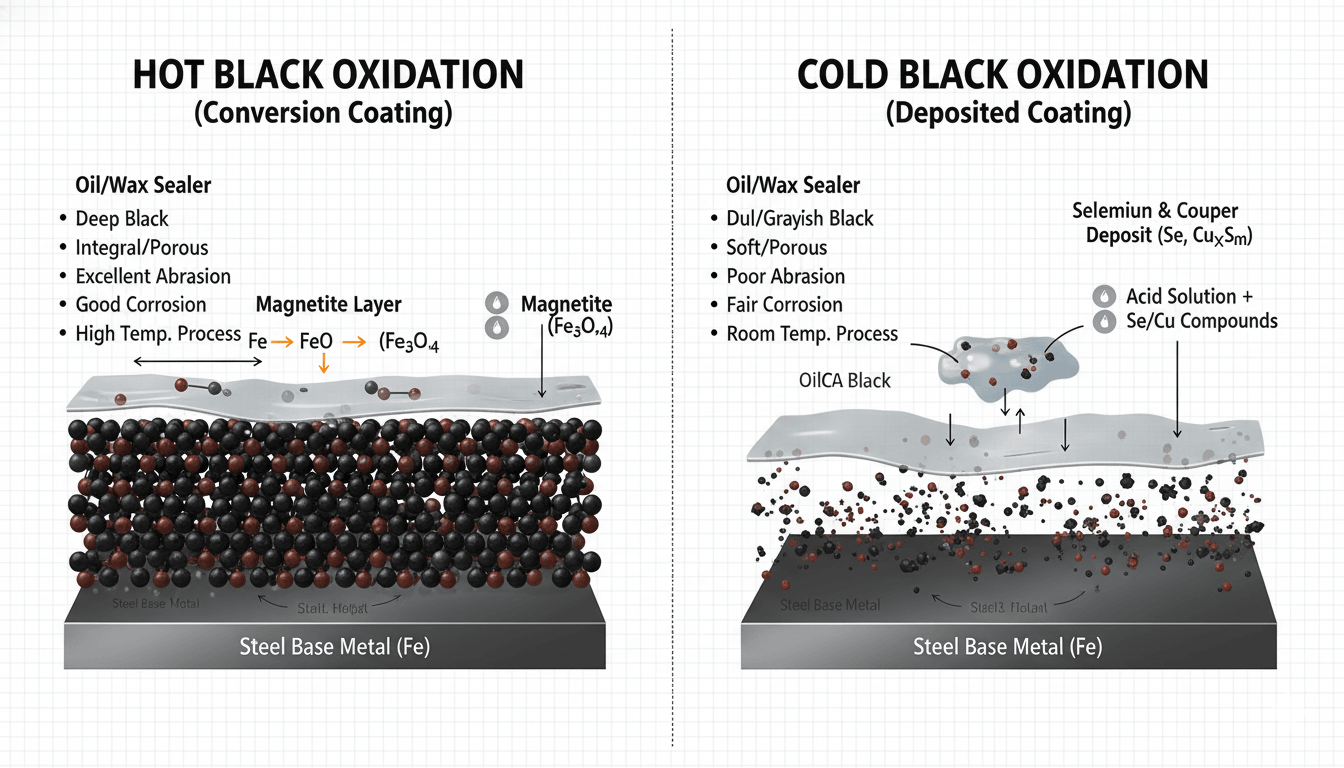

Hot black oxidation creates a durable, integrated iron oxide (Fe₃O₄) layer through a high-temperature process1, offering excellent wear and corrosion resistance2. In contrast, cold black oxidation applies a thin, cosmetic film at room temperature, providing only minimal, short-term protection.

When selecting a surface treatment for industrial blades, it is easy to get lost in technical terms. Both hot and cold black oxidation offer a black finish, but their performance is worlds apart. I have seen clients make choices that led to premature blade failure, simply because the difference was not clear. My goal is to break down these two processes so you can confidently choose the right one for your specific cutting application3. Let’s dive deeper into what sets them apart and where each one truly excels.

How Do The Underlying Mechanisms Of Hot And Cold Oxidation Differ?

Confused by the technical jargon of surface treatments? The process details can seem complex, making it hard to decide. I will break down the core differences in simple terms.

Hot black oxidation uses a high-temperature alkaline bath (135–150°C) to chemically convert the blade's surface into a hard, protective iron oxide. Cold black oxidation uses a room-temperature solution to deposit a thin, non-integrated black film onto the metal surface.

The easiest way I explain this to my customers is with an analogy. Hot black oxidation is like a callus forming on your skin. It is created from the original material, making it thicker, harder, and permanently part of the surface. It is incredibly tough. Cold black oxidation is more like applying paint to your skin. It covers the surface, but it is just a thin layer that can easily scratch or wear off.

This fundamental difference comes from the process itself. Hot oxidation is a true conversion coating. Cold oxidation is a chemical deposition process. This distinction is critical because it dictates everything about the coating’s performance, from its durability to its protective qualities. Here is a simple breakdown of the process differences.

Process Comparison

| Feature | Hot Black Oxidation | Cold Black Oxidation |

|---|---|---|

| Temperature | High (135–150°C) | Room Temperature (20–30°C) |

| Chemical Reaction | True oxidation (forms Fe₃O₄) | Chemical displacement (forms sulfides) |

| Layer Type | Integrated conversion layer | Deposited surface film |

| Energy Use | High | Low |

Which Coating Offers Better Protection And Durability For Your Blades?

A blade's coating directly impacts its lifespan and performance. Choosing incorrectly leads to premature wear and failure. Let's compare the protective qualities to ensure you get the best durability.

Hot black oxidation provides far superior protection. The thick, integrated Fe₃O₄ layer offers excellent, long-lasting corrosion and wear resistance4. The cold black oxide film is much thinner (around 0.5–1µm) and provides only minimal, short-term rust prevention5 with very limited wear resistance.

When we talk about protection, we are mainly focused on two things: fighting rust and resisting wear. On both fronts, hot black oxidation is the clear winner. The Fe₃O₄ layer created during the hot process is dense, stable, and chemically bonded to the steel. It becomes part of the blade. This creates a formidable barrier against moisture and oxygen, which are the main causes of rust.

In addition, this tough "callus" holds up incredibly well against friction during cutting. I have seen how this extends blade life in demanding industries. The cold-processed layer, being just a thin deposit, simply can't offer the same level of protection. It will rub off with use, exposing the bare metal underneath to both wear and corrosion.

Key Protective Properties

- Corrosion Resistance: The Fe₃O₄ layer from hot oxidation is dense and non-porous. It creates a strong, lasting barrier against moisture. The film from cold oxidation is more porous and wears off easily, quickly exposing the underlying metal to rust.

- Wear Resistance: Because it is integrated into the steel, the hot oxide layer withstands friction well. It is part of the metal. The deposited layer from cold oxidation can be scraped off easily during cutting operations, offering almost no benefit against wear.

- Oil Retention: A unique benefit of hot black oxidation is that the surface becomes slightly porous. This is excellent for retaining lubricating oils6, which further reduces friction and wear during operation, extending the blade's life even more.

When Should You Choose Hot Black Oxidation For Your Industrial Blades?

Is hot black oxidation always the answer? Not necessarily. Knowing its ideal uses prevents you from over-spending or misapplying the treatment. Let's explore its best-fit scenarios.

Choose hot black oxidation for blades that operate in high-humidity or high-friction environments7. It is ideal for high-performance blades like HSS and SKD11 used in paper cutting, packaging, and textiles, where durability and stability are critical for long-term production.

I always recommend hot black oxidation when performance and reliability are non-negotiable. If your cutting process involves moisture, abrasive materials8, or high speeds, this treatment is a sound investment. The enhanced corrosion resistance prevents rust from forming, which not only dulls the blade but can also contaminate your product. The superior wear resistance means fewer blade changes, less machine downtime, and more consistent cut quality over time.

For example, a client in Turkey's textile industry was facing a major issue. Their standard steel slitter blades were corroding rapidly in their humid facility, and the rust was staining the fabrics. This meant frequent, costly blade changes and rejected material. I recommended they switch to our SKD11 steel blades with a hot black oxidation finish. The results were immediate. The Fe₃O₄ layer completely prevented corrosion, and its natural ability to retain oil reduced friction during slitting. They reported a 40% increase in blade life and the complete elimination of fabric staining. This is a perfect example of hot oxidation's value in a harsh environment.

CommonBlade Applications

| Industry | Blade Type | Reason for Hot Black Oxidation |

|---|---|---|

| Paper & Converting | Guillotine Blades, Slitter Blades | Resists abrasion from paper dust, prevents rust from humidity |

| Packaging | Tray Sealers, Die-Cutting Blades | Withstands high friction, resists corrosion from cleaning |

| Textiles | Fabric Cutting Blades, Circular Knives | Prevents rust staining on fabric, reduces friction |

| Food Processing | Slicer Blades, Dicer Blades | Provides a corrosion-resistant and easy-to-clean surface |

Is Cold Black Oxidation Ever The Right Choice For Industrial Tools?

Cold blackening seems much less durable. So why does it even exist? Its specific advantages can be perfect for certain needs, saving you money if you know when to use it.

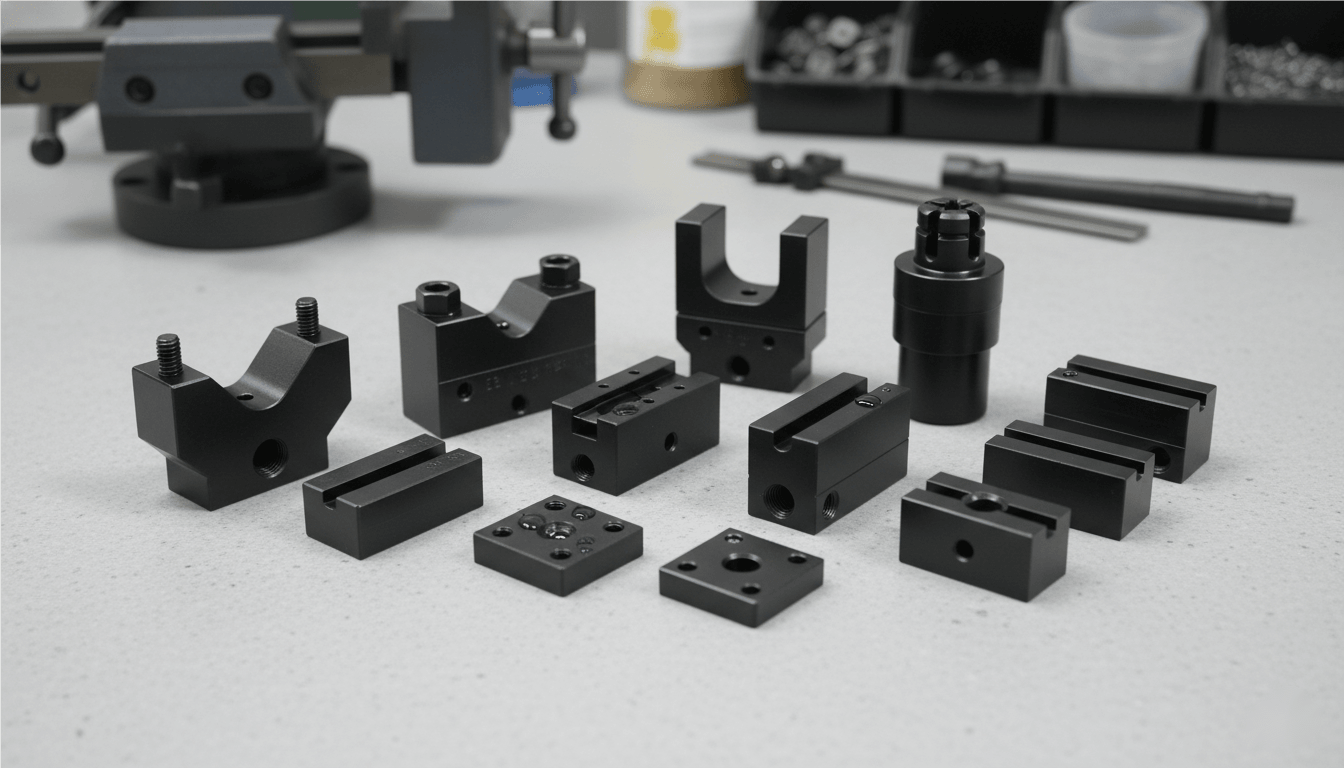

Yes, cold black oxidation is the right choice for parts that need a cosmetic black finish or short-term rust prevention without affecting dimensions. It is perfect for tool holders, clamping blocks, or positioning plates where the heat from hot oxidation could cause warping.

While it is not suitable for the cutting edge of a blade, cold blackening has a valuable place in the world of industrial tools. Its main advantage is that it is a room-temperature process. This means there is absolutely no risk of thermal distortion9 or changes to the material's temper. This is crucial for high-precision components where even a tiny change in dimension can cause major problems. It is also a simpler, lower-energy process, making it more cost-effective for parts where high performance is not the goal.

I worked with a manufacturer of plastic components in Mexico who needed a solution for their custom clamping blocks. These small, intricate parts held blades in place. They needed basic rust protection for storage and a uniform black look for easy identification. However, these blocks were machined to very tight tolerances. The high heat of hot oxidation would have warped them. We supplied their components with a cold black oxidation finish. It was the perfect solution. The process was inexpensive, did not alter the parts' dimensions, and provided the cosmetic finish and short-term rust prevention they required.

Key Advantages Of Cold Blackening

- No Thermal Distortion: As a room-temperature process, it is safe for high-precision parts that cannot be exposed to heat.

- Cost-Effective: The simple process uses less energy and less complex equipment, resulting in lower costs.

- Good for Aesthetics: It provides a uniform, deep black appearance, which is often used for identification or branding.

- Simple Application: The process is straightforward and can be done without specialized heating equipment.

Does Material Type Dictate The Best Blackening Method?

You picked the perfect process, but will it work on your blade's material? Applying a treatment to the wrong material is a definite way to waste money and destroy your tools.

Absolutely. Hot black oxidation is excellent for carbon and tool steels like HSS or SKD11, but it is destructive to tungsten carbide blades10. The high-temperature alkaline solution attacks the cobalt binder in carbide, severely weakening the blade and causing it to fail.

This is one of the most critical points I stress to my clients. Material compatibility is not just a recommendation; it is a rule. Hot black oxidation works by reacting with the iron in steel. For most steel blades, this is exactly what you want. However, some of the toughest, most wear-resistant blades are made from tungsten carbide, which is a composite material. Tiny carbide particles are held together by a metal binder, usually cobalt. The hot, caustic solution used in hot black oxidation aggressively attacks and dissolves this cobalt binder. This completely destroys the blade's internal structure, making it brittle and prone to chipping and breaking under the slightest stress.

I once averted a trouble for a large paper mill in Brazil that was cutting abrasive recycled paper. They wanted to improve the rust resistance of their new tungsten carbide slitter blades and were told by another supplier to use hot black oxidation. During a consultation, I immediately flagged this as a major risk. I explained how the process would ruin their expensive carbide blades. Instead, we recommended a Physical Vapor Deposition (PVD) coating11, such as TiN, which is applied in a vacuum and is perfectly safe for carbide. They achieved superior wear and corrosion resistance without compromising the blade's strength.

Material Compatibility Guide

| Material | Hot Black Oxidation | Cold Black Oxidation | My Professional Notes |

|---|---|---|---|

| High-Speed Steel (HSS) | Excellent | Suitable (less durable) | Hot is strongly preferred for performance and blade life. |

| Tool Steel (SKD11, D2) | Excellent | Suitable (less durable) | Hot is the industry standard for high-wear applications. |

| Tungsten Carbide | Extremely Unsuitable | Unsuitable (poor adhesion) | Never use hot oxidation. It destroys the cobalt binder. |

| Standard Carbon Steel | Good | Good | The choice depends on desired durability versus cost. |

Conclusion

Choosing between hot and cold black oxidation depends on your blade's material, application, and required durability. Hot provides robust, integrated protection, while cold offers a cosmetic, low-cost alternative.

Explore how high-temperature processes enhance the performance of blade coatings. ↩

Discover why corrosion resistance is vital for extending the lifespan of industrial blades. ↩

Understanding cutting applications helps in selecting the most effective blade coatings. ↩

Understanding wear resistance can help you choose the right coating for your cutting applications. ↩

Explore various rust prevention methods to enhance blade durability and performance. ↩

Discover the importance of oil retention in extending the life of industrial blades. ↩

Understanding high-friction environments can guide your choice of blade coatings. ↩

Learn how abrasive materials impact the choice of blade coatings for optimal performance. ↩

Learn about thermal distortion to avoid damaging high-precision components during treatment. ↩

Understanding the limitations of tungsten carbide blades can prevent costly mistakes. ↩

Explore PVD coating as a safe alternative for enhancing blade performance. ↩