Struggling with blade chipping1 and frequent replacements? Your blade material might be the problem. Choosing the right tungsten carbide2 can change everything for your cutting operations.

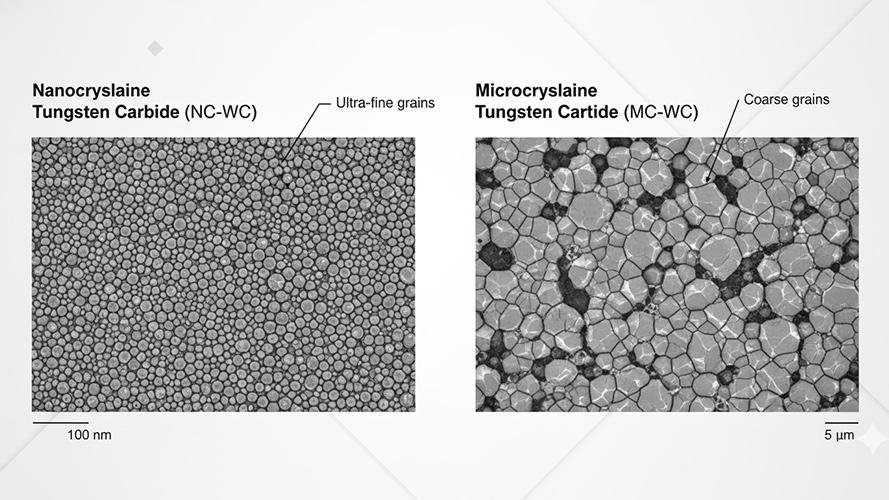

Nanocrystalline tungsten carbide has much smaller grains than conventional microcrystalline carbide. This ultrafine structure makes it tougher and more wear-resistant3, leading to longer blade life and cleaner cuts, especially in demanding applications. Conventional carbide is more brittle but is a cost-effective choice for general use.

This fundamental difference in grain size leads to significant performance variations. These differences are not just technical details; they have a real impact on your production line's efficiency, product quality, and overall costs. Let's explore how these materials stack up in real-world scenarios. Understanding these differences will help you select the perfect blade for your specific needs, saving you time and money.

How Does Grain Size Affect Blade Durability And Wear Resistance?

Are your blades wearing out too quickly, causing production delays? The material's internal structure is key. A small change in grain size4 can make a huge difference in performance.

Nanocrystalline carbide's smaller grains create more grain boundaries. This structure stops cracks from spreading, making the blade much tougher and more resistant to wear. Conventional carbide's larger grains are more prone to fracture, leading to a shorter usable life under high stress.

The main idea here is that a finer grain structure creates a stronger material. Think of it like a wall built with small, tightly packed stones versus one built with large, irregular boulders. The wall with smaller stones is more stable and better at resisting damage. In tungsten carbide, smaller grains mean more boundaries between them. These boundaries act as barriers that stop small cracks from growing and causing the blade to fail. This is why nanocrystalline carbide is much tougher.

Case Study: Brazilian Packaging Manufacturer

This client's blades chipped constantly. This led to frequent line stoppages and a lot of wasted material. I recommended they switch to nanocrystalline tungsten carbide blades. After the switch, they reported that their blade lifespan increased by three times. They also saw a significant reduction in defective products because the cuts were cleaner.

Here is a simple comparison:

| Feature | Nanocrystalline Carbide | Conventional Microcrystalline Carbide |

|---|---|---|

| Grain Size | <200 nanometers | 1-10 micrometers |

| Toughness | Very High | Moderate to Low |

| Wear Resistance | Excellent | Good |

| Typical Lifespan | Long | Standard |

Which Carbide Delivers Better Cutting Precision And Edge Quality?

Do you see rough edges or burrs on your cut materials? This compromises quality and may require secondary finishing. Your blade's edge retention is often the problem.

For high-precision tasks, nanocrystalline tungsten carbide is superior. Its fine-grain structure allows for an exceptionally sharp and durable cutting edge. This results in cleaner cuts with minimal burring. Conventional carbide blades, while sharp initially, dull faster and can't maintain the same level of precision.

A blade's ability to be sharpened to a fine point and hold that edge depends on its microstructure. The smaller, more uniform grains of nanocrystalline carbide create a more stable foundation for the cutting edge. This means the edge is less likely to micro-chip during use. It stays sharper for a longer period. This is especially important in industries where the final appearance of the cut edge is critical. Industries like textile manufacturing, film converting, and high-quality paper processing benefit greatly from this.

I remember working with a textile manufacturer in Turkey who faced this exact issue.

Case Study: Turkish Textile Producer

They were cutting delicate synthetic fabrics for a luxury clothing line. Their conventional microcrystalline blades were causing the fabric to fray along the cut. This was unacceptable for their high-end products. After I helped them upgrade to nanocrystalline blades, the problem disappeared. The cuts became perfectly clean, which eliminated the fraying and significantly improved their final product quality.

This table shows the key differences in cutting quality:

| Attribute | Nanocrystalline Carbide | Conventional Microcrystalline Carbide |

|---|---|---|

| Edge Sharpness | Extremely High | High |

| Edge Retention | Excellent | Fair |

| Cut Finish | Smooth, clean, no burrs | Can leave rough edges |

| Best For | Thin films, textiles, paper | General-purpose cutting |

How Do They Perform In High-Speed Or High-Impact Cutting?

Running your machines at high speeds but your blades can't keep up? High-impact or high-speed cutting5 creates intense stress and heat, leading to premature blade failure and risk.

Nanocrystalline tungsten carbide excels in high-speed and high-impact situations. Its enhanced toughness6 and fatigue resistance prevent chipping and catastrophic failure. Conventional carbide is more brittle and can shatter or crack under the same intense conditions, making it less reliable for demanding operations.

In cutting operations, toughness is a material's ability to absorb energy and resist fracturing. Nanocrystalline carbide is much tougher than conventional carbide. This makes it ideal for applications with interruptions or vibrations, like cutting thick or non-uniform materials. It also has better "red hardness." This means it stays hard even at the high temperatures generated by high-speed cutting. Conventional carbide, being more brittle, is more likely to crack or fail completely when subjected to sudden impacts or extreme heat, posing a safety risk.

A customer in Germany's paper converting industry highlighted this for me.

Case Study: German Paper Converter

This client was experiencing blade chipping while cutting dense, recycled cardboard at high speeds. This was a major safety concern and was causing expensive downtime for blade changes. We provided them with blades made from nanocrystalline carbide. The new blades handled the speed and impact without any issues. The client told me their productivity went up and their workplace became much safer.

Here is how they compare under stress:

| Performance Factor | Nanocrystalline Carbide | Conventional Microcrystalline Carbide |

|---|---|---|

| Impact Resistance | High | Low |

| High-Speed Suitability | Excellent | Limited |

| Heat Resistance | Excellent | Good |

| Failure Mode | Wears down predictably | Can chip or shatter suddenly |

When Is Conventional Carbide The More Economical Choice?

Is the higher price of advanced materials always justified? Budget is a major factor. Sometimes, a more affordable option is the smarter choice for your specific application.

Conventional microcrystalline carbide is significantly cheaper upfront. It is the perfect choice for general-purpose cutting where extreme precision or longevity is not the top priority. For standard applications in woodworking or basic packaging, it provides excellent performance for its cost.

While nanocrystalline carbide offers superior performance, its manufacturing process is more complex, which makes it more expensive. It's important to consider the total cost of ownership. This includes the initial price, blade life, downtime, and material waste. However, for many standard applications, the performance of conventional carbide is perfectly adequate. If you are not cutting difficult materials or running at extreme speeds, the extra cost of a nano-grade blade might not give you a worthwhile return.

I often advise clients to start by analyzing their specific cutting needs. For example, I worked with a client in Mexico who runs a large-scale box manufacturing plant.

Case Study: Mexican Box Manufacturer

This company cuts standard corrugated cardboard all day, every day. For their operation, the performance of our conventional microcrystalline blades was more than sufficient. The cuts were clean enough, and the blade life was predictable. The lower upfront cost allowed them to keep a larger inventory of replacement blades on hand. This minimized their downtime without forcing them to overspend on a technology they simply did not need. It was the best overall value for their business.

This table breaks down the cost considerations:

| Cost Factor | Nanocrystalline Carbide | Conventional Microcrystalline Carbide |

|---|---|---|

| Upfront Price | High | Low |

| Total Cost of Ownership | Can be lower in demanding jobs | Lower in standard jobs |

| Best Value For | High performance is critical | Cost-effectiveness is key |

| Common Industries | Composites, High-Tech Films | General Packaging, Woodworking |

Conclusion

Choosing the right carbide depends on your application. Nanocrystalline offers superior performance for demanding tasks, while conventional carbide provides great value for general use. Evaluate your needs to decide.

Understanding the causes of blade chipping can help you choose the right materials and improve your cutting operations. ↩

Explore the versatility of tungsten carbide and how it can enhance your cutting tools and operations. ↩

Find out which materials offer the best wear resistance for your cutting needs. ↩

Learn how grain size influences the performance and durability of cutting materials. ↩

Explore the challenges and solutions for maintaining blade performance in high-speed cutting. ↩

Discover the importance of toughness in materials and how it affects cutting tool performance. ↩