Are your industrial blades failing prematurely or proving difficult to machine? This causes costly downtime and wasted materials, making you wonder if the problem is the steel itself.

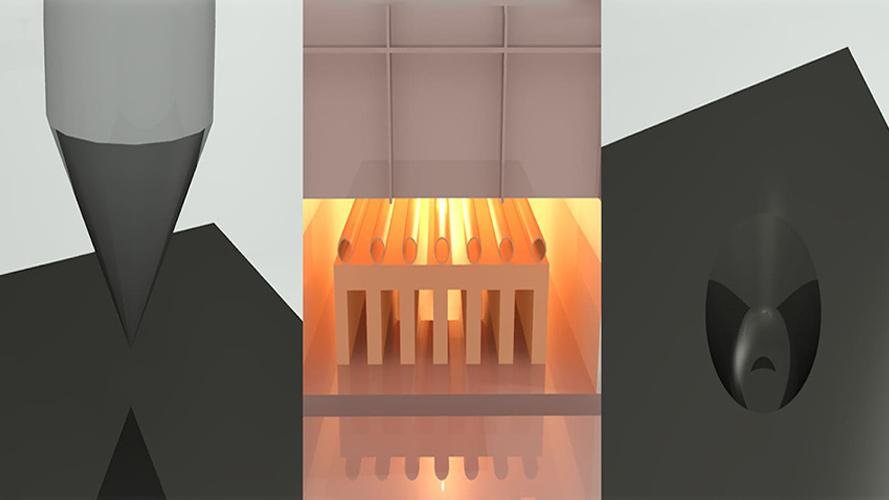

The solution often lies in the heat treatment1. Normalizing enhances a blade's strength2 and toughness3 by air cooling it from a high temperature. Annealing, however, uses slow furnace cooling to soften the metal, reduce stress, and make it easier to machine. Normalizing is for performance; annealing is for processability.

These two heat treatments seem similar, but they produce very different results for your blades. Choosing the right one at the right time is critical for performance and longevity. Let's look closer at how each process helps us create the perfect cutting solution4 for our partners around the world.

How Does Normalizing Enhance Blade Strength And Durability?

Your blades chip or fracture when cutting tough materials. This forces you to replace them constantly, hurting your production schedule and budget. Normalizing creates a stronger, more uniform steel structure.

Normalizing refines the steel's grain structure5 by heating it above its critical temperature (over 850°C) and then air-cooling it. This process removes internal inconsistencies and creates a tougher, more resilient blade that resists wear and impact, significantly extending its service life.

When we normalize steel for a blade, we are essentially hitting the reset button on its internal structure. Heating it dissolves coarse, uneven grains. The subsequent air cooling forces new, much finer grains to form. This fine, uniform structure is the key to a blade's strength and toughness. I remember a client in Germany running a metal recycling plant. Their shear blades were constantly failing when cutting reinforced steel bars. The problem was an inconsistent hardness6 in their old blades, which created weak spots. We supplied them with new shear blades made from D2 tool steel that we normalized before the final hardening. This pre-treatment step ensured the steel's structure was perfectly homogenized. The result was a blade that could withstand extreme impact without chipping.

Key Benefits Of Normalizing

A normalized blade has a significantly improved microstructure. This makes it ideal for heavy-duty cutting, where toughness is just as important as hardness.

| Feature | Before Normalizing | After Normalizing |

|---|---|---|

| Grain Structure | Coarse and irregular | Fine and uniform |

| Hardness | Inconsistent | Consistent and uniform |

| Toughness | Lower | Significantly higher |

| Performance | Prone to chipping | High impact resistance |

When Is Annealing The Best Choice For Improving Blade Machinability?

You need a complex custom blade, but the hard material is impossible to machine accurately. This leads to manufacturing errors, wasted steel, and delays in getting the blades you need.

Annealing is the best choice when a blade requires extensive or intricate machining. By heating the steel to a specific temperature and cooling it very slowly in a furnace, we reduce its hardness and relieve internal stresses. This makes the material soft and easy to cut, perfect for precise shaping.

Think of annealing as making the steel workable. Hard steel is brittle. Trying to cut or drill it with precision can cause it to crack or warp. Annealing changes that. It makes the steel soft enough to be milled, ground, and shaped with high accuracy. Recently, I worked with a food processing company in Brazil that needed a very specific circular blade for portioning frozen fish. The design had complex notches and a unique beveled edge. Machining this from hardened steel would have been a nightmare. So, our process involved annealing the steel blank first. This made it soft and stable. Our technicians could then machine the intricate details perfectly without risking fractures. After machining, we proceeded with the final hardening and tempering to give the blade its required sharpness and durability.

Annealing's Role In Manufacturing

Annealing is a crucial intermediate step for creating complex blades. It allows for precision that would otherwise be impossible.

| Stage | Process | Goal |

|---|---|---|

| 1. Annealing | Slow furnace cool | Soften steel, remove stress |

| 2. Machining | Milling, drilling, grinding | Shape the blade with precision |

| 3. Hardening | Quenching | Increase hardness for cutting edge |

| 4. Tempering | Re-heating to lower temp | Increase toughness, reduce brittleness |

How Do Normalizing And Annealing Work Together To Create The Perfect Blade?

You are not sure if your blade needs one heat treatment or another, or maybe both. Choosing incorrectly can result in a blade that is either too brittle or too soft for its job.

Normalizing and annealing are not mutually exclusive; they are often used together in a multi-step process. Normalizing is first applied to the raw steel to create a strong foundation. Annealing is then used after initial shaping to prepare the blade for precise final machining by softening it.

For the highest quality blades, we almost always use both processes. It is all about applying the right treatment at the right stage of manufacturing. A great example comes from a partner in Italy's packaging industry. They needed slitter knives for cutting corrugated cardboard, a surprisingly abrasive material. Their existing blades were dulling far too quickly. For their new blades, we started with a high-carbon steel7 billet and first normalized it. This gave the raw material a great, tough base structure. Then, we rough-cut the blade shapes. After that, we annealed the rough shapes to relieve stress from the cutting and make them ready for precision grinding. Only after the final profile was perfectly ground did we perform the final hardening and tempering. This comprehensive approach resulted in a superior blade that delivered exceptional performance and service life.

Combined Heat Treatment Workflow

This sequence ensures optimal properties at every stage of manufacturing, from the raw material to the final product.

| Step | Process | Purpose | Blade Condition |

|---|---|---|---|

| 1 | Normalizing | Refine raw billet grains | Strong and tough |

| 2 | Rough Machining | Create basic blade shape | Stresses induced |

| 3 | Annealing | Relieve stress, soften | Soft and machinable |

| 4 | Final Machining | Create final edge/profile | Precise and accurate |

| 5 | Hardening/Tempering | Get final performance | Hard, tough, and wear-resistant |

Conclusion

In short, normalizing builds strength while annealing enables precision. Understanding how to use both correctly is our secret at PASSION to crafting blades that deliver performance and unparalleled value.

Discover various heat treatment methods and their impact on metal properties. ↩

Explore this resource to discover advanced techniques and insights on improving blade strength for optimal performance. ↩

Gain insights into the importance of toughness in industrial blades. ↩

Explore innovative cutting solutions that enhance efficiency and effectiveness. ↩

Explore the significance of grain structure in determining material performance. ↩

Learn about the critical balance between hardness and toughness in blade design. ↩

Discover why high-carbon steel is preferred for durable industrial blades. ↩