Are you confused by the terms tungsten and tungsten carbide? Choosing the wrong material leads to poor performance and high costs. Understanding the key differences ensures you get the right blade.

Tungsten is a pure chemical element, while tungsten carbide is a man-made compound. Tungsten carbide is created by combining tungsten and carbon atoms, resulting in a material that is dramatically harder and more wear-resistant. For industrial blades1, tungsten carbide is almost always the superior choice.

I talk to customers every day about blade materials2. The confusion between tungsten and tungsten carbide comes up a lot. While they share a name, they are completely different in practice. Let's break down the important questions I often hear. This will help you understand why tungsten carbide is chosen to ensure the precision and durability of the blades.

Is Tungsten Carbide Stronger Than Pure Tungsten?

Do you need a blade that can withstand tough cutting jobs? You might think pure tungsten is strong, but it may not be tough enough for your application, leading to frequent replacements. Knowing the difference in strength helps you choose a truly durable blade.

Yes, tungsten carbide is much more effective for industrial cutting. Pure tungsten is dense and heat-resistant, but tungsten carbide's structure gives it superior hardness3 and wear resistance4. This makes it the ideal material for industrial blades that must stay sharp under extreme pressure and use.

When we talk about "strength" for a blade, we are usually talking about two things: hardness and wear resistance. Hardness is the ability to resist being scratched or dented. Wear resistance is the ability to last a long time without getting dull. Tungsten carbide excels in both areas far more than pure tungsten. Pure tungsten is a relatively soft metal on its own. It's not suitable for holding a sharp cutting edge. Tungsten carbide, however, is one of the hardest materials available, second only to diamond.

Key Property Comparison

| Property | Pure Tungsten | Tungsten Carbide | Why It Matters For Blades |

|---|---|---|---|

| Hardness | Moderate (4.5 Mohs) | Extremely High (9.0-9.5 Mohs) | A harder blade stays sharper for much longer. |

| Wear Resistance | Average | Excellent | Resists abrasion, extending the blade's life. |

| Toughness | Average | Good (Varies by grade) | Resists chipping and breaking from impacts. |

I remember a client in Turkey who manages a large textile plant. They were cutting heavy synthetic fabrics with standard steel blades. The abrasive nature of the material was dulling their blades in just a few hours, causing constant production delays. I recommended they try tungsten carbide blades. They were amazed. The new blades lasted for weeks, not hours. This simple switch drastically reduced their downtime and blade replacement costs. This is a perfect example of how tungsten carbide’s superior hardness directly translates to real-world performance and efficiency.

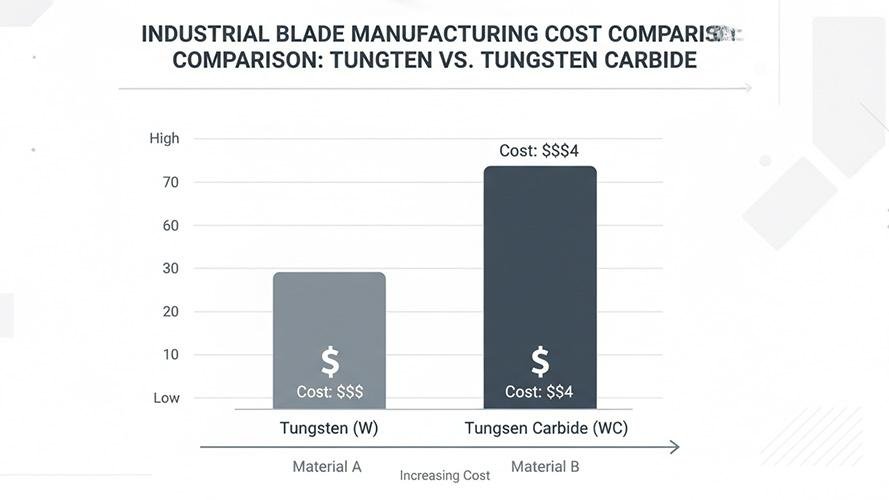

Which Is More Expensive, Tungsten Or Tungsten Carbide?

Are you worried about the cost of your industrial blades? The price tag can be confusing. Choosing a blade based only on its initial cost can be a very expensive mistake in the long run. Let's look at the real cost to find the true value.

Tungsten carbide is more expensive than pure tungsten if you compare them by weight. This is because making tungsten carbide is a very complex process. It involves mixing tungsten powder with carbon and a binder like cobalt, then heating it under pressure. This process uses more energy and skill.

It's true that a tungsten carbide blade has a higher upfront price than a blade made from a simpler material. The manufacturing process for tungsten carbide is highly technical. We use a method called powder metallurgy. We carefully mix fine powders of tungsten and carbon, add a binder metal like cobalt, and then sinter it in a furnace at very high temperatures. This creates an incredibly dense and hard final product. This process requires specialized equipment and expertise, which adds to the cost.

However, the initial price is not the whole story. I always encourage my customers to think about the Total Cost of Ownership (TCO).

Understanding True Cost

- Initial Cost: The price you pay for the blade.

- Replacement Cost: How often you need to buy new blades.

- Downtime Cost: Money lost when production stops for a blade change.

- Labor Cost: The time your team spends changing blades.

A customer of mine in Mexico runs a large packaging facility. They hesitated to switch to our tungsten carbide slitter blades because of the higher price. They cut corrugated cardboard all day, which is surprisingly abrasive and wears down blades quickly. I showed them a TCO calculation. Even though our blades cost more initially, they would last at least 10 times longer than their steel blades. They agreed to a trial run. After three months, their own data confirmed it. They saved a significant amount of money because of fewer blade changes and less production downtime. The higher initial investment paid for itself many times over.

When Should You Choose Tungsten Carbide For Your Blades?

Are you unsure which material is right for your specific cutting job? Using the wrong blade can damage your product, wear out your machines, and waste a lot of time and money. Let's clarify when tungsten carbide is the best choice for you.

You should choose tungsten carbide blades for high-speed cutting5 and when you are working with abrasive materials. This includes things like fiberglass6, thick plastics, corrugated board7, and certain metals. Its amazing hardness and wear resistance ensure a long life and a clean cut in tough situations.

As a rule, if your current blades are getting dull too fast, tungsten carbide is likely the answer. Its ability to hold a sharp edge under stress is unmatched by most other materials. This means you get more precise cuts for a longer period, which improves the quality of your final product. However, it's also important to know that not all tungsten carbide is the same. The amount of cobalt binder8 can be adjusted to change its properties.

Application Guide

| Application / Material | Recommendation | Reason |

|---|---|---|

| Abrasive Plastics & Composites | Tungsten Carbide (Low Cobalt) | Maximum wear resistance is needed for these very abrasive materials. |

| Paper & Corrugated Board | Tungsten Carbide (Standard Grade) | Resists the abrasive dust and provides a clean, long-lasting cut. |

| Food Processing (Frozen/Tough) | Tungsten Carbide (Higher Cobalt) | The extra cobalt adds toughness to resist chipping from an impact. |

| Thin Film & Foil | Tungsten Carbide (Micro-grain) | A very fine grain structure allows for an extremely sharp, durable edge. |

I worked with a food processing9 company in Italy that was having trouble dicing large blocks of frozen vegetables. Their steel blades were chipping and wearing out constantly. The hardness of tungsten carbide was the obvious solution, but I was concerned about the impacts from hitting the hard, frozen food. A blade that is too hard can be brittle. So, we provided them with a custom blade made from a tougher grade of tungsten carbide, which has a slightly higher percentage of cobalt binder. This small change gave the blade the extra impact resistance it needed. The solution worked perfectly, improving their uptime and product consistency. It shows that choosing tungsten carbide is the right first step, and picking the right grade is the key to success.

Conclusion

In short, tungsten is an element, but tungsten carbide is the high-performance material you need for durable and precise industrial cutting. Choosing tungsten carbide is an investment in your productivity.

Explore various industrial blade types to find the best fit for your cutting needs. ↩

Explore various blade materials to find the best options for your specific cutting needs. ↩

Learn how hardness impacts the longevity and effectiveness of cutting blades. ↩

Discover the significance of wear resistance in prolonging blade life and reducing costs. ↩

Find out which materials are best suited for high-speed cutting to enhance productivity. ↩

Discover the ideal blades for cutting fiberglass to ensure clean and efficient cuts. ↩

Learn about the best cutting tools for corrugated board to improve your production process. ↩

Discover how cobalt binder affects the properties and performance of tungsten carbide blades. ↩

Explore the best blade options for food processing to ensure safety and efficiency. ↩