Struggling to know the perfect time to change your blades? Waiting too long ruins product quality, but changing too early wastes money. This simple metric can solve your problem.

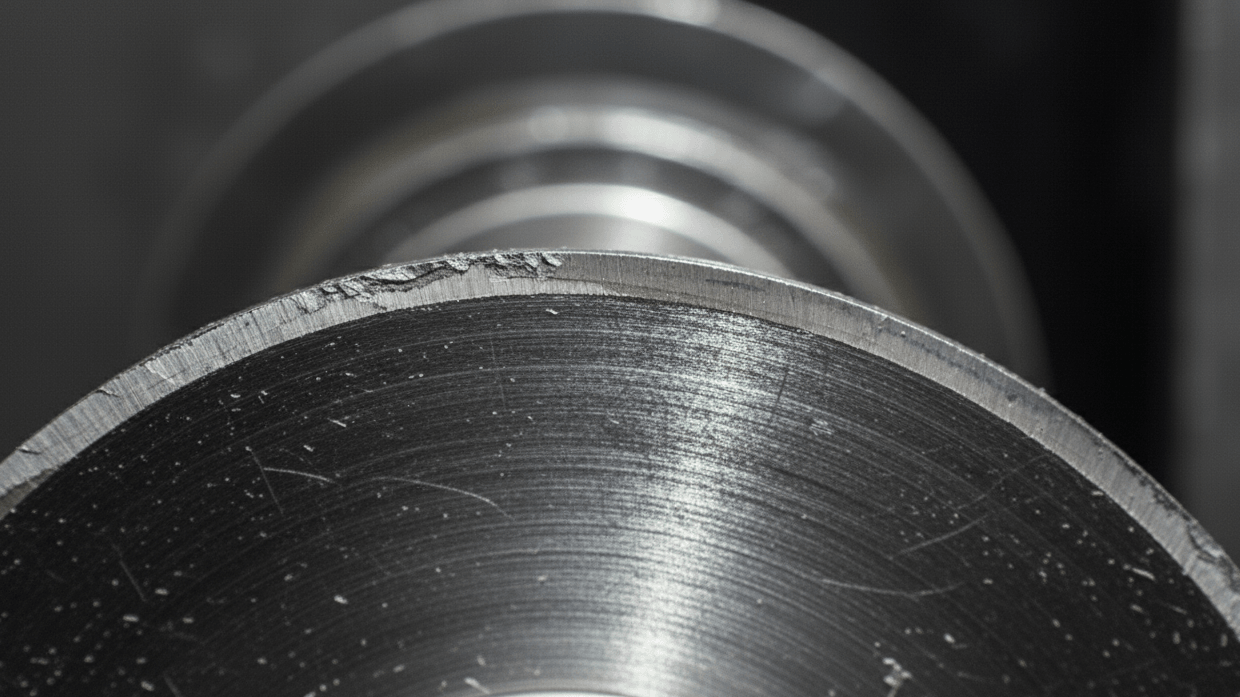

The effective wear length1 is the specific part of an industrial blade's edge that does the actual cutting and shows wear. It's not the full edge length, but a key metric showing when a blade is dull and needs replacement to maintain cut quality.

Knowing what it is is one thing, but how does this concept translate into real-world benefits for your production line? It’s more than just a technical term; it's a powerful tool for efficiency. Let's explore how you can use this knowledge to your advantage.

How Do You Accurately Measure The Effective Wear Length?

Trying to measure blade wear with just your eyes? This often leads to inaccurate guesses and costly mistakes. Precise measurement is key to optimizing performance without complex lab equipment.

You can measure effective wear length using tools like a toolmaker's microscope2 or high-magnification digital cameras. These instruments allow you to accurately see and measure the "wear land"—the flattened area on the blade's flank—against a predefined wear criterion3 for your specific application.

Measuring wear accurately is critical. While a quick visual check can spot major damage, it won't give you the precise data needed for optimal blade management. True measurement involves looking at the flank wear4, a small flat surface that forms on the cutting edge as it dulls. The goal is to measure the width of this wear land. When it reaches a specific, predetermined size (the wear criterion), it's time to change the blade. This criterion varies depending on the material you're cutting and the quality you need.

A client of mine in Indonesia, let's call him Budi, was struggling with inconsistent slitting quality in his film packaging plant. They were changing blades based on a fixed schedule. I helped them implement a simple system using a USB microscope to check the wear land. By setting a clear wear criterion of 0.2 mm, they started changing blades based on actual condition, not just time. Their waste dropped by 15% and blade life increased by an average of 20%.

Common Measurement Methods

| Method | Pros | Cons |

|---|---|---|

| Visual Inspection | Quick, no tools needed | Inaccurate, only for major wear |

| Toolmaker's Microscope | Highly accurate, reliable | Slower, requires equipment |

| Digital Microscope/Camera | Good accuracy, easy to document | Requires investment, setup |

Why Is Monitoring Effective Wear Length So Crucial For Production?

Think blade wear is just a small maintenance issue? This oversight can lead to poor cuts, machine strain, and rising energy bills. Monitoring wear is a simple fix for these bigger problems.

Monitoring wear length is crucial because it directly impacts production efficiency, quality, and cost. It prevents issues like burrs, inaccurate cuts, and increased machine stress. This data-driven approach allows for predictive maintenance, maximizing blade life while ensuring consistent, high-quality output.

Paying close attention to the effective wear length moves you from reactive to proactive maintenance. It’s not just about avoiding bad cuts; it’s about optimizing the entire system. When a blade dulls, the cutting force required increases significantly. This doesn't just produce a rougher edge; it puts extra strain on your machinery's motors and bearings, leading to higher energy consumption and premature equipment failure. Not long ago, I worked with a paper converting company in Mexico. They were experiencing frequent web breaks, which they attributed to the paper stock. After we analyzed their slitter blades, we found the flank wear was far beyond acceptable limits. By introducing regular wear checks, they could predict the exact point their blades would start causing micro-tears in the paper. The web breaks disappeared, and their line uptime improved dramatically.

Key Production Benefits

| Benefit | Description |

|---|---|

| Improved Quality | Prevents burrs, delamination, and dimensional inaccuracies. Ensures every product meets specifications. |

| Reduced Costs | Lowers energy consumption and extends the life of both the blades and the machine itself. |

| Increased Uptime | Allows you to schedule blade changes before they fail, preventing unplanned production stops. |

What Factors Influence The Rate Of Effective Wear On A Blade?

Do your blades wear out faster than expected? This unpredictability can disrupt your entire production plan and budget. Several key factors are at play, and you can control them.

Blade wear rate is influenced by the blade material and geometry, the material being cut, and operational parameters like cutting speed5 and angle. Harder or more abrasive materials will cause faster wear, as will running the machine at speeds higher than recommended for the blade.

Blade wear isn't random; it's the result of a specific set of conditions. Optimizing these conditions can dramatically extend the life of your blades. Think of it as a three-part equation: the blade itself, the material it's cutting, and how you're using it. Each part plays a critical role in how quickly that effective wear length grows. A customer in the textile industry in Poland was cutting synthetic fabrics and found their blades were dulling in just a few days. I learned they were using a standard steel blade at a very high speed to meet quotas. We switched them to a blade with a specific carbide grade and recommended lowering the cutting speed by 15%. Not only did the cut quality improve, but their blade life tripled, saving them significant money on replacements and downtime.

1. The Blade Itself

The material (e.g., tungsten carbide vs. high-speed steel), the hardness, and the cutting edge geometry are fundamental. A sharper angle might cut cleaner initially but will wear faster.

2. The Material Being Cut

Cutting abrasive materials like fiberglass-reinforced plastic will wear a blade much faster than cutting soft paper. Contaminants in the material can also act like sandpaper on the cutting edge.

3. Operational Parameters

| Parameter | Impact on Wear |

|---|---|

| Cutting Speed | Too high a speed generates excess heat, softening the blade edge and accelerating wear. |

| Feed Rate | Pushing the blade too aggressively increases friction and force, leading to rapid dulling. |

| Blade Angle/Alignment | Incorrect alignment causes uneven force distribution, concentrating wear on one small spot. |

Conclusion

In short, monitoring effective wear length is not just a technical detail. It is a key strategy for improving quality, cutting costs, and maximizing your production uptime.

Understanding effective wear length can help you optimize blade usage and improve production efficiency. ↩

Find out how a toolmaker's microscope can enhance precision in measuring blade wear. ↩

Understanding wear criterion is essential for effective blade replacement and maintenance. ↩

Explore the concept of flank wear to better manage your cutting tools and improve performance. ↩

Understanding the relationship between cutting speed and blade wear can optimize your cutting processes. ↩