Struggling with poor cuts and industrial blades that wear out too fast? This inefficiency costs time and money. Understanding the blade's front angle is the secret to perfect cuts every time.

The industrial blade's front angle, or rake angle, dictates how it engages the material. Its primary function is to control cutting forces and chip flow1. A positive angle cuts smoothly, a negative one adds strength, and a neutral angle offers a balance, directly impacting efficiency and blade life.

This angle might seem like a small detail, but its impact is huge. The right choice depends entirely on your material and your goals. Let's break down how each type of front angle works so you can make the best decision for your operation.

How Does A Positive Front Angle Boost Cutting Efficiency?

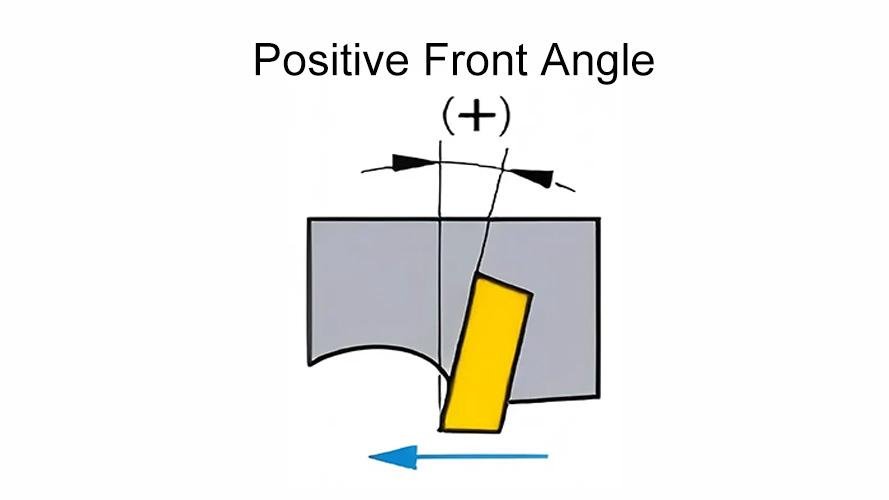

Are your cuts leaving rough edges or damaging delicate materials? This leads to wasted product and customer complaints. A positive front angle2 provides a sharper, cleaner cut, solving this issue.

A positive front angle tilts the cutting edge forward into the material. This reduces cutting resistance, generates less heat, and requires less power. It results in a superior surface finish, especially on softer materials like plastics, paper, and non-ferrous metals, significantly improving overall efficiency.

A blade with a positive front angle acts more like a sharp knife. It creates a shearing action that slices cleanly through the material. This is very different from the brute-force approach of other geometries. Because it cuts so easily, the blade and the material stay cooler. This is critical for preventing material deformation, especially in heat-sensitive plastics or thin films. The smooth evacuation of chips along the blade face also prevents buildup that can ruin the cut.

I remember a client in Italy who runs a large food packaging operation. They were struggling with cutting thin plastic films. Their existing blades were causing the film to stretch and tear, leading to a high rejection rate. I analyzed their setup and recommended a custom blade with a high positive front angle. The change was immediate. The blade sliced through the film with almost no resistance, creating a perfectly clean edge. They were able to increase their machine speed by 15% and cut their material waste by more than half.

Balancing Sharpness And Strength

However, this sharpness comes at a cost. The keen cutting edge is inherently weaker and more fragile. It is not suitable for hard materials or for "interrupted cuts" where the blade repeatedly impacts the material. Here is a quick breakdown:

| Advantages of Positive Angle | Disadvantages of Positive Angle |

|---|---|

| Lower cutting forces | Weaker cutting edge |

| Less heat generation | Prone to chipping on hard materials |

| Better surface finish | Not ideal for interrupted cuts |

| Reduced power consumption | Shorter life in abrasive applications |

When Is A Negative Front Angle The Stronger Choice?

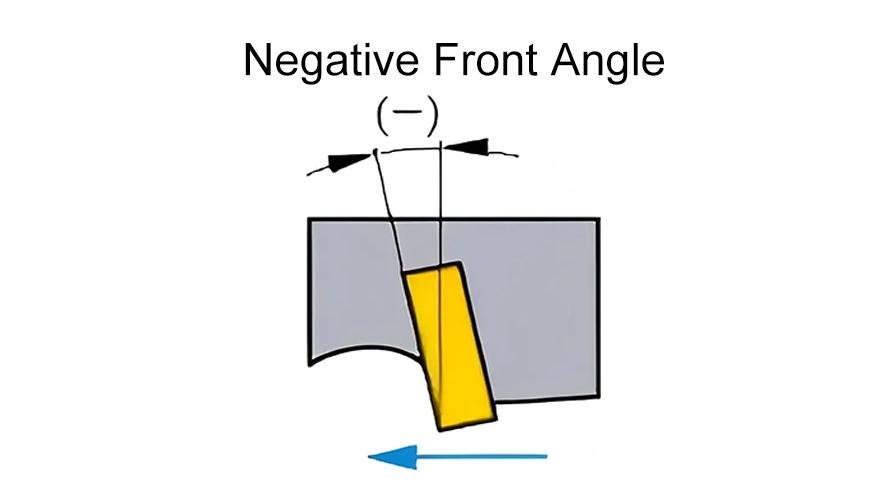

Are shattered blade edges and constant downtime crippling your heavy-duty cutting? This constant replacement is expensive and frustrating. A negative front angle3 provides the brute strength needed for tough jobs.

A negative front angle tilts the cutting edge away from the material, reinforcing the blade tip. This design is best for cutting hard, brittle materials or for interrupted cuts where impact is high. It prioritizes blade durability and longevity over achieving the lowest possible cutting force.

Think of a negative front angle blade as a plow. It uses its strength to push through the material. This design puts more metal directly behind the cutting edge, which drastically increases its strength and resistance to shock. While this creates higher cutting forces and generates more heat, it is the only way to survive demanding applications. This is the geometry you need for cutting high-hardness metals, composites, or materials with inconsistent densities. The focus here is not on a perfect finish, but on getting the job done without the blade failing.

I cooperated with a metal recycling facility in Germany that faced this exact problem. They process large bundles of mixed scrap metal. The constant impact from the interrupted cuts was shattering their blades within a few hours. I suggested they try a blade made from a tough tungsten carbide4 grade with a significant negative front angle. The machine had to work a bit harder, but the results were incredible. Their blade life increased by over 300%, turning a major point of failure into a reliable part of their process.

Prioritizing Durability Over Finish

The trade-off for this extreme durability is efficiency. The increased forces demand a rigid, powerful machine and can lead to a rougher surface finish5.

| Advantages of Negative Angle | Disadvantages of Negative Angle |

|---|---|

| Maximum edge strength | Higher cutting forces |

| Excellent for interrupted cuts | Generates more heat |

| Highly resistant to chipping | Requires more power from the machine |

| Long life in hard materials | Can produce a rougher surface finish |

Why Might A Neutral Front Angle Be The Most Reliable Option?

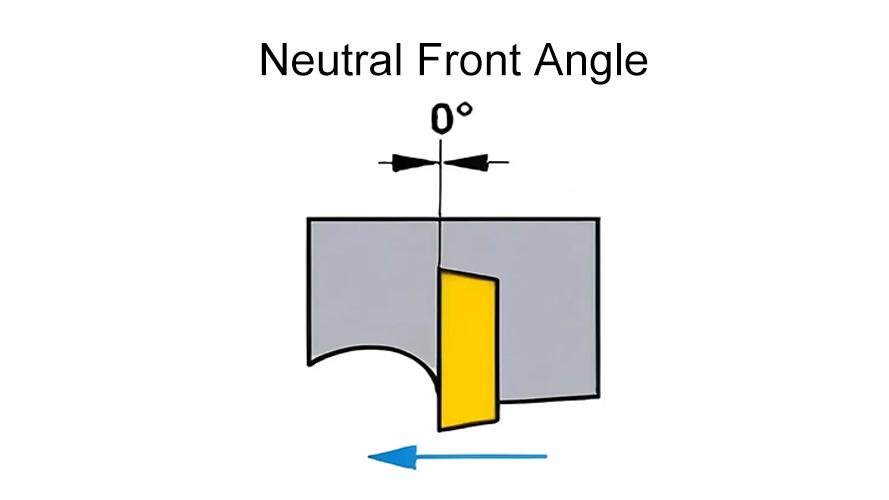

Need a single blade solution for various materials but find specialized blades too limiting? Juggling different blades complicates inventory. A neutral front angle offers a versatile, reliable "do-it-all" performance.

A neutral (or zero) front angle positions the cutting edge perpendicular to the workpiece. This provides a solid balance between the cutting ease of a positive angle and the strength of a negative one. It's a general-purpose choice, excellent for automated lines and medium-hardness materials.

A neutral front angle is the jack-of-all-trades in blade geometry. It doesn't offer the pristine finish of a high positive angle or the brute strength of a negative angle. Instead, it provides good, consistent performance across a wide range of conditions. This makes it a very practical and economical choice for many industries. Because the geometry is simple, these blades are often easier and less expensive to manufacture and resharpen. The key to using a neutral angle blade effectively is ensuring chips are cleared away from the cutting zone, as they can sometimes cause rubbing and premature wear.

A perfect example is a client I have in Brazil who manages a huge paper mill. Their automated lines cut everything from thin newsprint to thick cardboard packaging. They needed a blade that could handle this variety without constant adjustments or swaps. We supplied them with a durable blade featuring a neutral front angle. It delivered predictable performance and a long service life, regardless of the paper stock. This drastically simplified their tool management and maximized uptime on their production lines.

The Jack-Of-All-Trades Geometry

This balanced approach makes it a go-to for many automated and multi-purpose production environments where reliability is more important than specialized peak performance.

| Advantages of Neutral Angle | Disadvantages of Neutral Angle |

|---|---|

| Good balance of strength and sharpness | Not optimal for any single task |

| Versatile across many materials | Potential for chip crowding |

| Simple, easy-to-manufacture geometry | May not provide the best surface finish |

| Reliable and predictable performance | Less efficient than a positive angle |

Conclusion

Choosing the right front angle is not just technical—it's strategic. By matching the angle to your material and goals, you can dramatically improve efficiency, cut quality, and your bottom line.

Understanding chip flow is essential for maintaining cutting efficiency and preventing blade damage. ↩

A positive front angle enhances cutting efficiency and surface finish, making it ideal for softer materials. ↩

A negative front angle is crucial for cutting hard materials and ensuring blade durability in tough applications. ↩

Tungsten carbide blades offer exceptional durability and performance, especially in demanding applications. ↩

The geometry of a blade directly impacts the surface finish, which is critical for product quality. ↩