Are you struggling with messy tape cuts and frequent blade changes? This inefficiency wastes material and slows production. The solution lies in a tiny detail: the blade’s edge radius.

The optimal blade radius for tape cutting is typically between 0.01 mm and 0.03 mm. For thin plastic tapes, a sharper radius around 0.02 mm works best. For thicker, reinforced tapes, a slightly larger radius around 0.05 mm adds durability and prevents chipping.

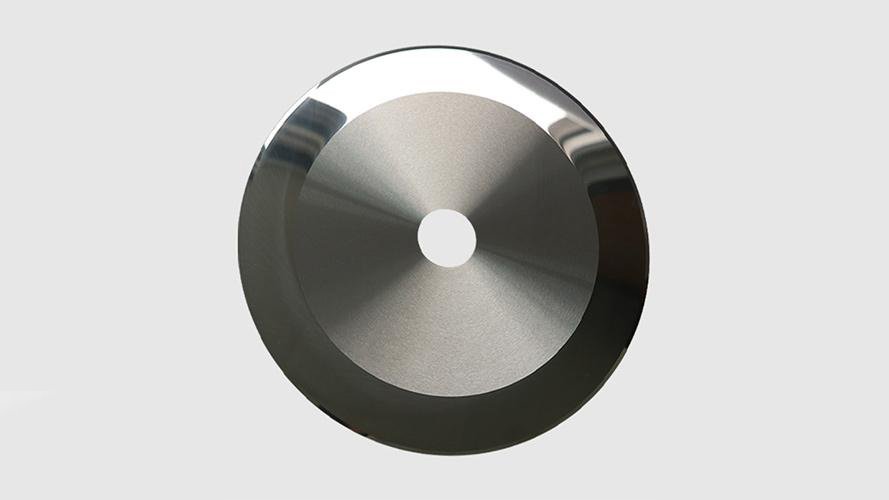

Theoretically, a 'perfect' cutting edge should be a line with no thickness, formed where two planes meet. But in the real world, due to material physics and manufacturing, the tip of any blade is not a perfect line. It is actually a tiny arc, and the radius of this arc is what we call the 'edge radius'. I see the question about the "best" radius a lot in my work. People want a single number, but the truth is, the perfect radius is not one-size-fits-all. It is a careful balance that depends on your tape, your machine, and your production speed. Let's explore how we find the perfect cutting edge1 for your needs.

How Does Tape Type Influence The Blade Radius Choice?

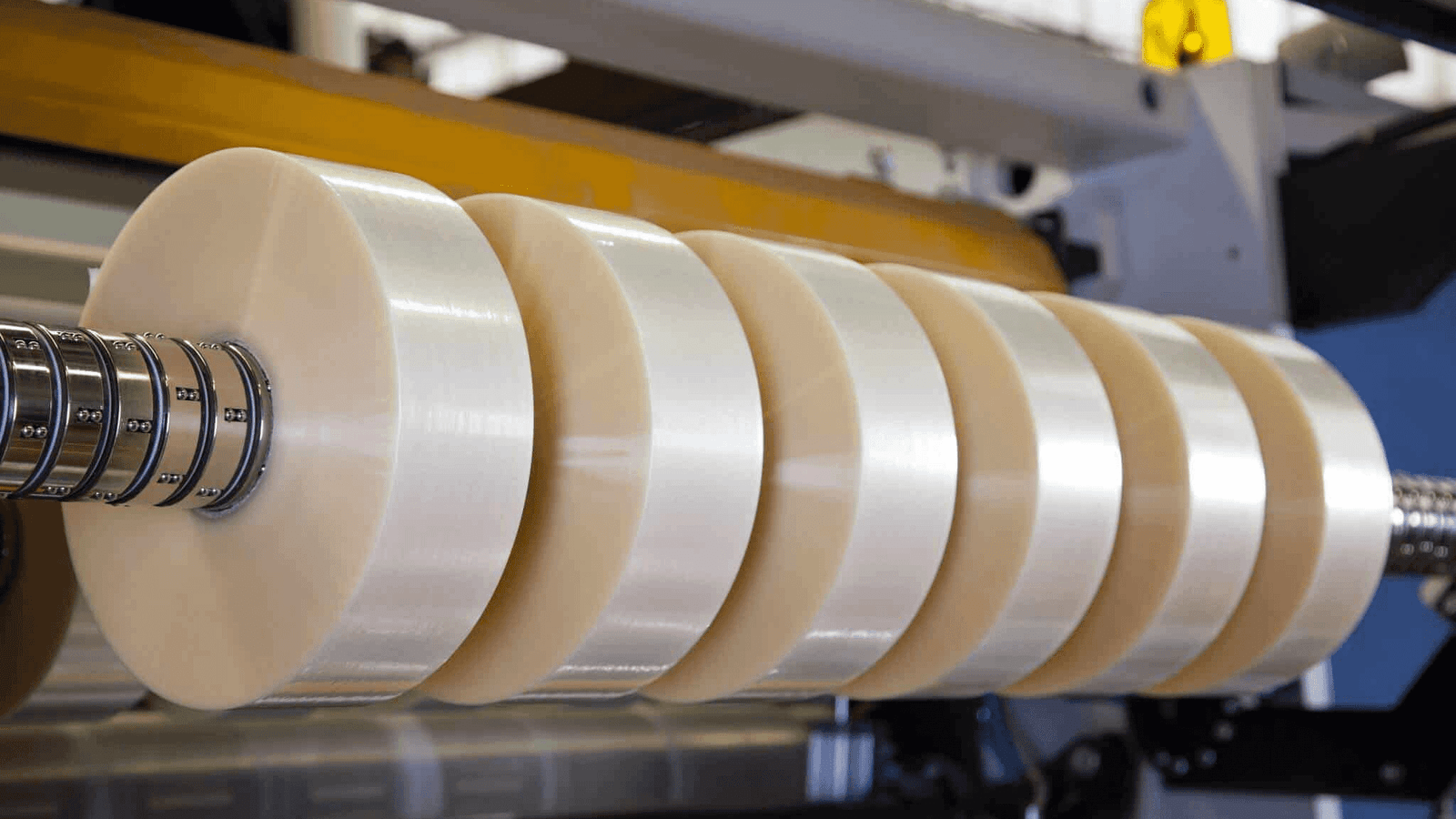

Using one blade for all tapes often leads to poor results and waste. This "one-size-fits-all" approach just doesn't work. The secret is matching the blade radius to the tape.

For thin plastic tapes like BOPP, PET, or PVC, a smaller radius of around 0.02 mm ensures a sharp, clean cut. For thicker or fiber-reinforced tapes, a larger radius of about 0.05 mm provides the needed strength to prevent the edge from chipping or wearing out too quickly.

When I talk to clients, the first thing I ask is, "What are you cutting?" The material itself tells us where to start. A blade that works wonders on packaging tape will likely fail when cutting a thick, fiber-reinforced strapping tape. The physics are simple. Thin films need a blade that slices through with minimal force. A very sharp edge, with a small radius, penetrates the material cleanly without deforming it. But if you use that same sharp edge on a tough, abrasive material, it will chip almost instantly. For those tougher jobs, we need an edge with more support behind it—a slightly larger radius. This creates a stronger, more durable cutting point that can handle the stress.

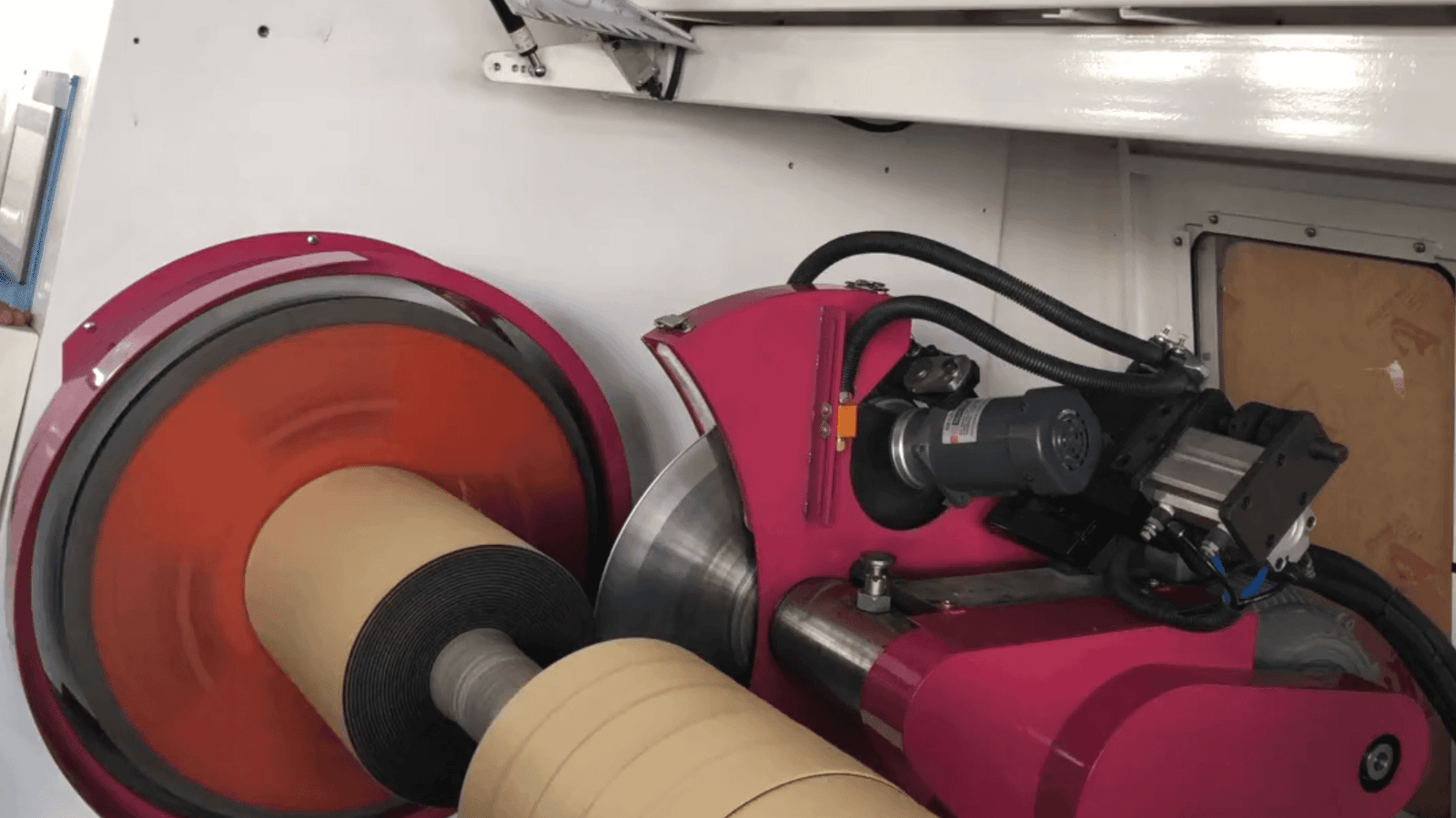

Real-World Application

I once worked with a packaging company in Germany. They were using a standard blade to slit large rolls of BOPP tape and were frustrated with the inconsistent, slightly jagged edges. This was causing issues in their automated packaging machines down the line. After discussing their process, I realized their blade radius was too large for such a thin film. It was pushing and tearing the material more than slicing it. We supplied them with a custom blade2 featuring a highly polished edge with a small 0.02 mm radius. The change was immediate. Their cuts became perfectly clean, which eliminated their downstream problems and even reduced production dust.

| Tape Type | Common Materials | Recommended Radius | Reason |

|---|---|---|---|

| Thin Film Tapes | BOPP, PET, PVC | ~0.02 mm | Allows for a clean slice with minimal material deformation. |

| Thick Industrial Tapes | Duct Tape, Gaffer Tape | ~0.03 mm - 0.04 mm | Balances sharpness with the durability needed for thicker adhesives. |

| Reinforced Tapes | Filament, Strapping | ~0.05 mm | Provides extra edge strength to cut fibers without chipping the blade. |

Why Do Blade Material And Coatings Matter Just As Much As Radius?

You found the right radius, but your blades are still failing quickly or gumming up. The blade's material is just as critical. The perfect sharpness means nothing if it doesn't last.

The best radius must be paired with the right material and coating. For tape cutting, carbide and highly polished stainless steel are excellent choices for holding a sharp edge. Adding a coating like TiN, DLC, or CrN further reduces friction and prevents sticky adhesive from building up.

I've seen many companies invest in sharp blades, only to see performance drop because of adhesive buildup3. Tape is, by nature, sticky. That stickiness creates friction and residue that clings to the blade. Over time, this "gumming" effect makes the blade act dull, even if the edge is still sharp. This is where material science comes in. At PASSION, we often recommend highly polished stainless steel because its smooth surface offers less for adhesive to grab onto. For even tougher situations, we turn to coatings. Think of a coating as a non-stick layer for your blade. A Diamond-Like Carbon (DLC) coating, for example, is incredibly slick and hard. It drastically reduces friction, which means less heat, less adhesive buildup3, and a much longer cutting life for the blade. The blade material4 provides the foundation for strength, while the coating provides the lasting performance.

Real-World Application

I remember a client in Mexico who manufactures specialty medical tapes. The adhesive they used was extremely tacky and their blades were gumming up within an hour, forcing production to a halt for cleaning. They were using standard steel blades. After analyzing their needs, I suggested a two-part solution. First, we switched them to a high-grade, polished stainless steel blade to reduce the initial sticking. Second, we applied a DLC coating5. The result was transformative. Their blade life increased from one hour to over a full day of production before needing a change. They could run their lines continuously, which significantly boosted their output and reduced operator frustration.

| Feature | Benefit for Tape Cutting | Best For |

|---|---|---|

| Carbide Material | Holds a sharp edge longer than steel. | High-volume, abrasive cutting applications. |

| Polished Stainless Steel | Naturally smooth surface reduces adhesive buildup3. | General-purpose and food-grade tape cutting. |

| TiN Coating | Increases surface hardness and wear resistance. | When you need a good balance of performance and cost. |

| DLC/CrN Coating | Provides an extremely low-friction surface. | Demanding applications with very sticky adhesives. |

How Do Production Settings Like Speed And Pressure Affect The Ideal Radius?

Is your line running faster, but now your cut quality is suffering? Increasing production speed changes the forces on your blade. What worked at a slower pace may fail under high-speed demands.

Your production settings directly impact the ideal blade radius. For high-speed cutting, you generally need a smaller radius to minimize cutting resistance and heat buildup. At lower speeds, you can often use a slightly larger, more durable radius to extend the blade's working life.

It's all about physics. When a blade cuts through tape, it generates force and friction. As you increase the cutting speed, both of these factors multiply. A blade with a larger radius, even if it's strong, will create more drag and push against the material more at high speeds. This can lead to heat buildup, material stretching, and a messy cut. A sharper blade with a smaller radius slices through with less resistance, making it ideal for fast-paced operations. However, there's a trade-off. That extremely sharp edge is more delicate. If your process is slower and more controlled, you may not need that level of sharpness. In that case, opting for a slightly larger radius can give you a blade that resists wear and lasts much longer, saving you money on replacements.

Real-World Application

A client in Vietnam was scaling up production for their line of packaging materials. They had recently invested in new machinery that could run significantly faster. But when they increased the speed, their old blades started leaving burnt marks and jagged edges on the tape. They thought the blades were defective. I spoke with their production manager and learned about the speed increase. I explained that the added velocity was creating too much friction for their current blade geometry. We recommended they switch to a blade with a smaller edge radius and a TiN coating. The smaller radius reduced the cutting force, while the coating helped dissipate heat. This allowed them to run their machines at full speed while maintaining perfect cut quality. It was a simple adjustment that unlocked the full potential of their new equipment.

| Production Factor | Impact on Blade Choice | Recommendation |

|---|---|---|

| High Cutting Speed | Increases friction and cutting force. | Use a smaller radius (~0.02 mm) to reduce resistance. |

| Low Cutting Speed | Less stress on the blade edge. | A larger radius (~0.03 mm) can be used for better durability. |

| High Cutting Pressure | Puts more stress on the blade tip. | A stronger, slightly larger radius may be needed to prevent chipping. |

| Low Cutting Pressure | Less force applied to the blade. | A sharper, smaller radius will work effectively. |

Conclusion

Finding the optimal blade radius is not about one single number. It is a balance of tape type, blade material, coating, and production settings to achieve precision and efficiency.

Exploring the concept of a perfect cutting edge can enhance your understanding of blade performance. ↩

Custom blades can be tailored to specific needs, enhancing efficiency and precision. ↩

Preventing adhesive buildup is crucial for maintaining blade sharpness and efficiency. ↩

Choosing the right blade material can significantly impact cutting efficiency and longevity. ↩

DLC coating can enhance blade performance and lifespan, making it a valuable investment. ↩