Are your cuts messy or your blades wearing out too fast? The problem might be the blade's edge geometry. This leads to downtime, material waste, and lost profits.

A beveled edge turns a forceful cut into a clean shear. This wedge-like design reduces cutting force1, controls waste material flow, and protects the blade itself. This simple feature is key to extending tool life, improving cut quality, and saving energy in your operations.

The design of a blade’s edge is more than just making it sharp. It is about precision engineering2. It is the foundation for achieving efficiency and quality. Let's look deeper into how this works.

How Do Core Mechanical Principles Enhance Guillotine Blade Functionality?

High energy bills and messy cuts slowing you down? Your guillotine blade is working too hard. This extra force wears out your machinery and produces rough, unusable material edges.

The beveled edge works like a wedge, creating a clean slicing action instead of a messy fracture. This lowers the energy needed to cut. It also guides chips away from the blade and the material, preventing jams and scratches, which ultimately extends the blade's life.

The mechanics behind the bevel are simple but very powerful. A well-designed bevel makes the blade do the work, not the machine. I remember a client in Brazil who runs a flexible packaging company. They were cutting thin polymer films and faced two problems: their blades were dulling very quickly, and the film edges were jagged. I took a look at their process. The guillotine blades they used had a small bevel angle. This design is better for hard materials. For their soft film, it was compressing and tearing the material instead of cutting it. I suggested they switch to one of guillotine blades with a steeper bevel.

Reducing Cutting Force

The new guillotine blade sliced through the film with much less resistance. Their machine ran smoother and quieter, and they even noticed a drop in energy consumption.

Controlling Chip Flow

The steeper angle also changed how the waste material came off. Instead of getting tangled, the thin plastic strips curled away cleanly from the cutting area.

Extending Tool Life

The biggest win was the blade's lifespan. Because the cutting edge was no longer taking a beating, the blade life doubled. The client went from changing blades twice a week to just once. We used this table to track the improvements.

| Metric | Before (Small Bevel) | After (Optimized Bevel) |

|---|---|---|

| Cutting Action | Compression & Tearing | Clean Shear Separation |

| Energy Use | High | Reduced by over 10% |

| Blade Lifespan | ~100 hours | ~200 hours |

| Edge Quality | Jagged, with micro-tears | Smooth and precise |

Which Bevel Type Is Right For Your Application?

Are you using a one-size-fits-all blade for different materials? This approach is likely costing you money. The wrong bevel type can lead to blade chipping, poor cuts, and wasted material.

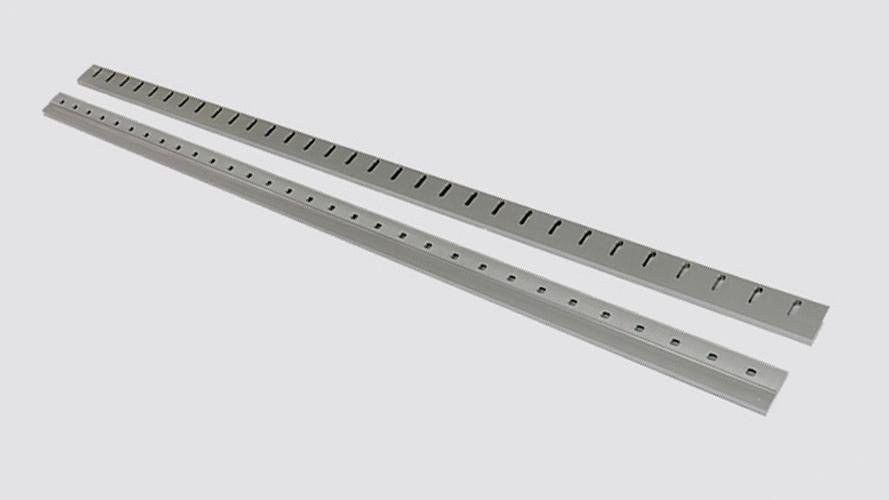

Single-bevel blades are very strong and are great for heavy-duty jobs like shearing sheet metal. Double-bevel blades are sharper and create a more balanced cut. This makes them perfect for precision work, like slitting paper or film, where a perfect edge is critical.

It’s not that one bevel is better than the other. The key is to match the guillotine blade to the job. I work with clients on this decision all the time. A few years ago, I helped a paper converting company in Germany. Their job was to slit massive paper rolls into narrower ones, and the cut quality had to be perfect for their printing clients. They were using some very durable single-bevel blades. The blades lasted a long time, but they caused a slight curl on one side of the paper edge. This tiny defect was causing big problems in their printing machines later on.

Single-Bevel Blades: The Workhorse

These blades have one ground edge. They are incredibly strong and can handle a lot of force, which is why they are common in metal shearing. But the force is all on one side, which can push or curl softer materials.

Double-Bevel Blades: The Precision Blade

I suggested they test asymmetrical double-bevel blades. These blades have edges ground on both sides. This balances the cutting forces, keeping the material perfectly flat as it's cut. The result was immediate. The paper edges were perfectly straight and clean on both sides. The balanced force from the double-bevel design completely solved their curling issue.

| Feature | Single Bevel | Double Bevel |

|---|---|---|

| Strength | High | Moderate to High |

| Sharpness | Good | Excellent |

| Force Balance | Unbalanced | Balanced |

| Best For | Heavy shearing, metal | Precision slitting, film, paper |

How Do You Balance Sharpness Against Blade Strength?

Your ultra-sharp blades are chipping and breaking too soon. Does this sound familiar? Trying to get the sharpest edge possible can lead to a weak blade, causing expensive downtime and frequent replacements.

A steeper bevel makes a blade sharper but also makes the edge thinner and more fragile. The secret is finding the right balance for your material. Harder, thicker materials need a smaller angle for more strength. Softer, thinner materials can use a larger angle for more sharpness.

This is the most common conversation I have with my clients. Everyone wants the sharpest blade, but a blade that breaks easily is useless. It really is a balancing act. I had a great experience working through this with a textile company in Turkey. They were cutting very thick, dense industrial fabrics. They needed a clean cut, so they were using blades with a very steep bevel angle. The blades were incredibly sharp, but the edges were getting tiny chips after just a few hours. The downtime for blade changes was hurting their production schedule.

The Sharpness Vs. Strength Dilemma

A sharp edge cuts cleanly with less force. A strong edge resists chipping3 and lasts longer. We needed to find a way to get both.

Making The Right Decision

We proposed a new blade design. We slightly reduced the main bevel angle to add more strength. Then, we added a tiny "micro-bevel4" right at the tip of the cutting edge. This micro-bevel reinforces the edge without sacrificing too much sharpness. The new design was a huge success for them. The blades still cut cleanly through the tough fabric, but the tool life increased by over 300%. We found their perfect balance.

| Material Characteristic | Optimal Bevel Angle | Main Consideration |

|---|---|---|

| Soft & Thin (e.g., plastic film) | Large Angle (Steeper Bevel) | Maximize Sharpness |

| Hard & Thick (e.g., metal sheet) | Small Angle (Shallower Bevel) | Maximize Strength & Durability |

| Tough & Fibrous (e.g., textiles) | Medium Angle + Micro-bevel | Balance of Sharpness & Strength |

Conclusion

The beveled edge is not just a detail. It is the core of your cutting performance. Choosing the right design ensures efficiency, quality, and profitability in your operations.

Learn how cutting force impacts your machinery and cutting quality for better operations. ↩

Delve into precision engineering to enhance your cutting tool effectiveness. ↩

Explore this resource to understand how to prevent blade chipping, ensuring longer tool life and reduced downtime. ↩

Explore this resource to understand how micro-bevels enhance blade durability and cutting efficiency, crucial for optimizing your operations. ↩