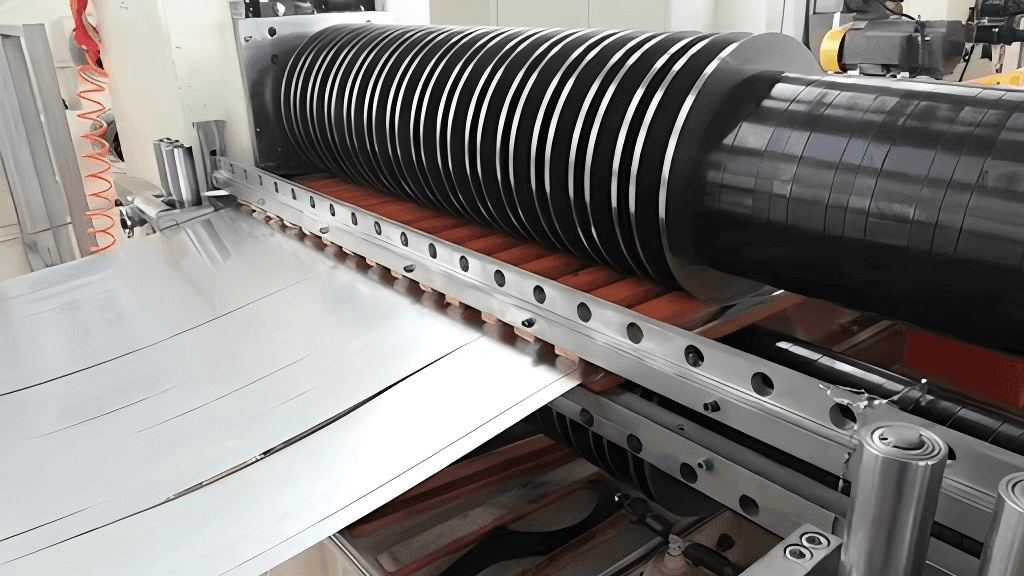

Struggling with inconsistent cuts and short blade life? Tiny geometric flaws are often the cause. These issues can lead to poor quality and equipment damage, but understanding them solves it.

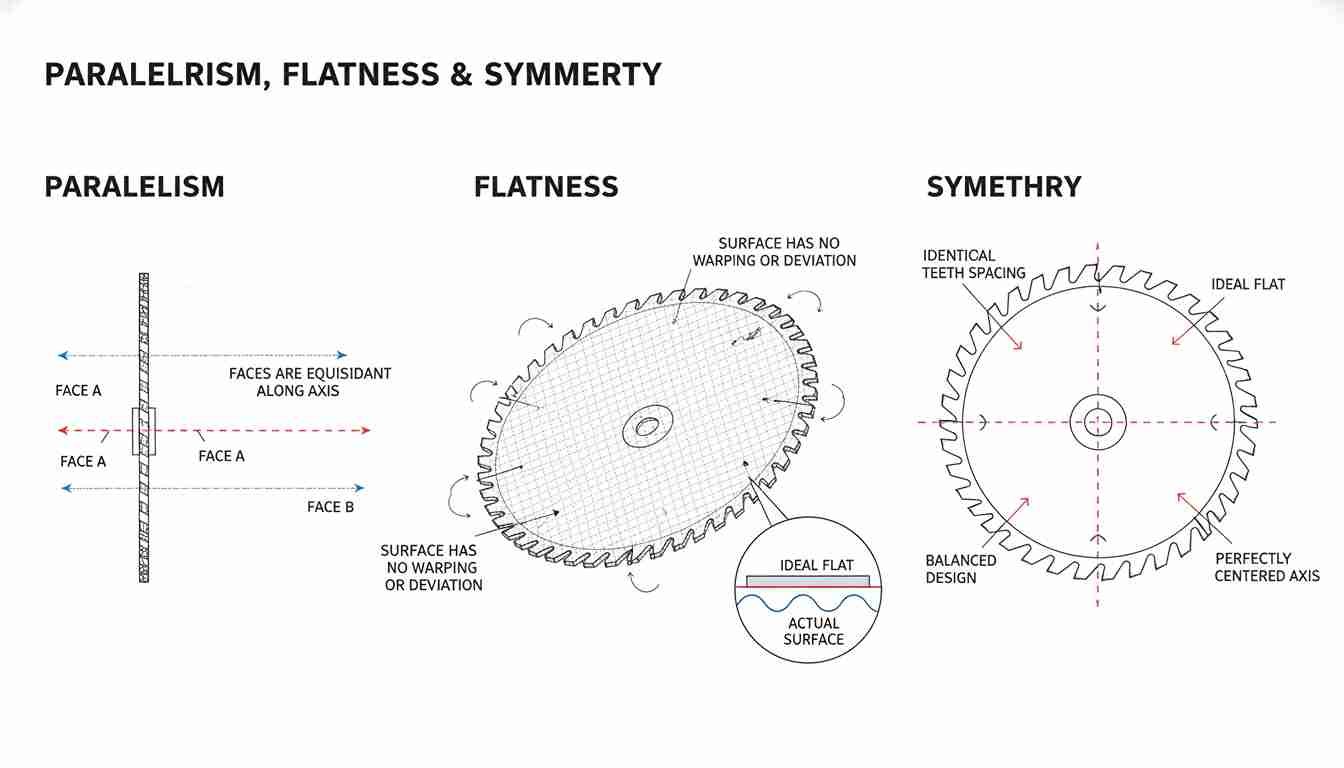

Flatness1 is the foundation, ensuring a single surface is even. Parallelism2 controls the relationship between two surfaces, making thickness uniform. Symmetry3 ensures the blade is balanced for smooth, high-speed rotation. These three factors together determine a blade's precision and stability.

Many clients often think the issue is sharpness or material hardness alone. But the real culprits are often three technical terms: flatness, parallelism, and symmetry. These are not just words on a spec sheet. They have a direct impact on your production line, your costs, and your final product quality. Understanding the link between them is crucial for choosing a blade that performs reliably day after day. To really get it, we need to look at each one. Let's start with the most basic one: flatness. You'll see why we at PASSION are so obsessed with getting this first step right.

Why Is Flatness The Foundation For A Good Blade?

A warped blade causes inconsistent pressure and ruins cuts. This leads to wasted material and frequent blade changes. Ensuring true flatness is the first step to a perfect cut.

Flatness is the foundation because it ensures the entire blade surface makes even contact with the material. Without a perfectly flat surface, you can't achieve proper parallelism or symmetry, leading to instability and poor cutting performance from the very start.

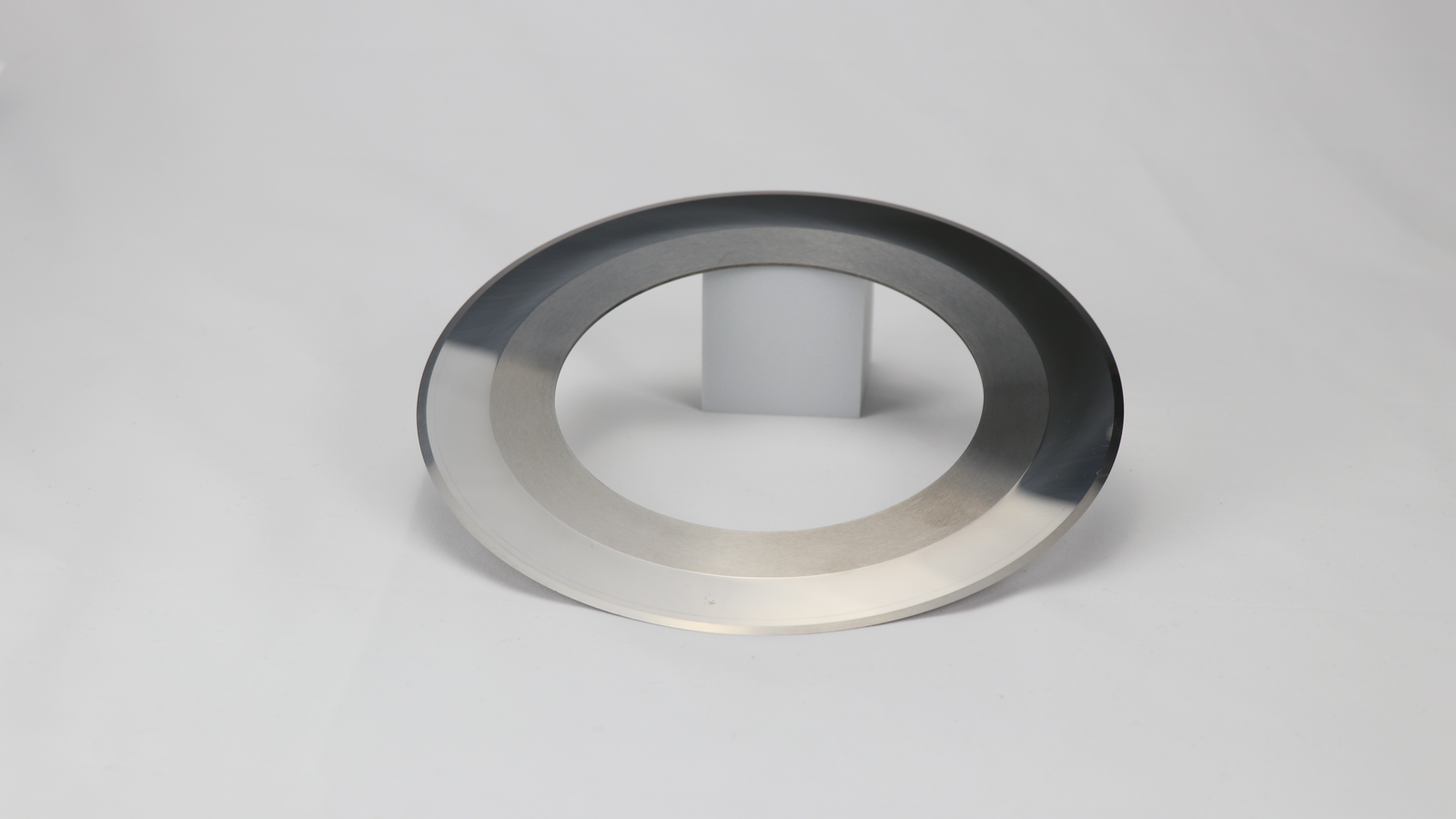

Flatness is just what it sounds like: how flat a single surface of the blade is. We measure it by how much the surface deviates from a perfect, ideal plane. I remember a client, let's call him Noah from Germany, who runs a plastic film extrusion line. He was getting what he called "tiger stripes" on his product, which meant inconsistent thickness and a lot of scrapped material. He blamed his slitting machine, but after a quick check, we found the issue was his blades. They looked flat to the naked eye, but our precision gauges4 showed significant warping. This tiny imperfection meant the blade wobbled as it cut, creating high and low pressure points on the film. This is why flatness is the absolute starting point for blade quality.

Impact Of Poor Flatness

A blade that isn't flat will cause a chain reaction of problems. It’s the single most important geometric feature to control during manufacturing.

| Defect | Consequence |

|---|---|

| Warping or Bending | Creates an inconsistent cutting gap, leading to uneven cuts. |

| Surface Waves | Increases vibration and noise during high-speed operation. |

| Local Dents/High Spots | Causes uneven wear on the blade edge, shortening its lifespan. |

This is why our manufacturing process starts with achieving near-perfect flatness on every single blade. It isn’t just a specification; it’s the bedrock of the entire blade's quality and performance. Without it, everything else fails.

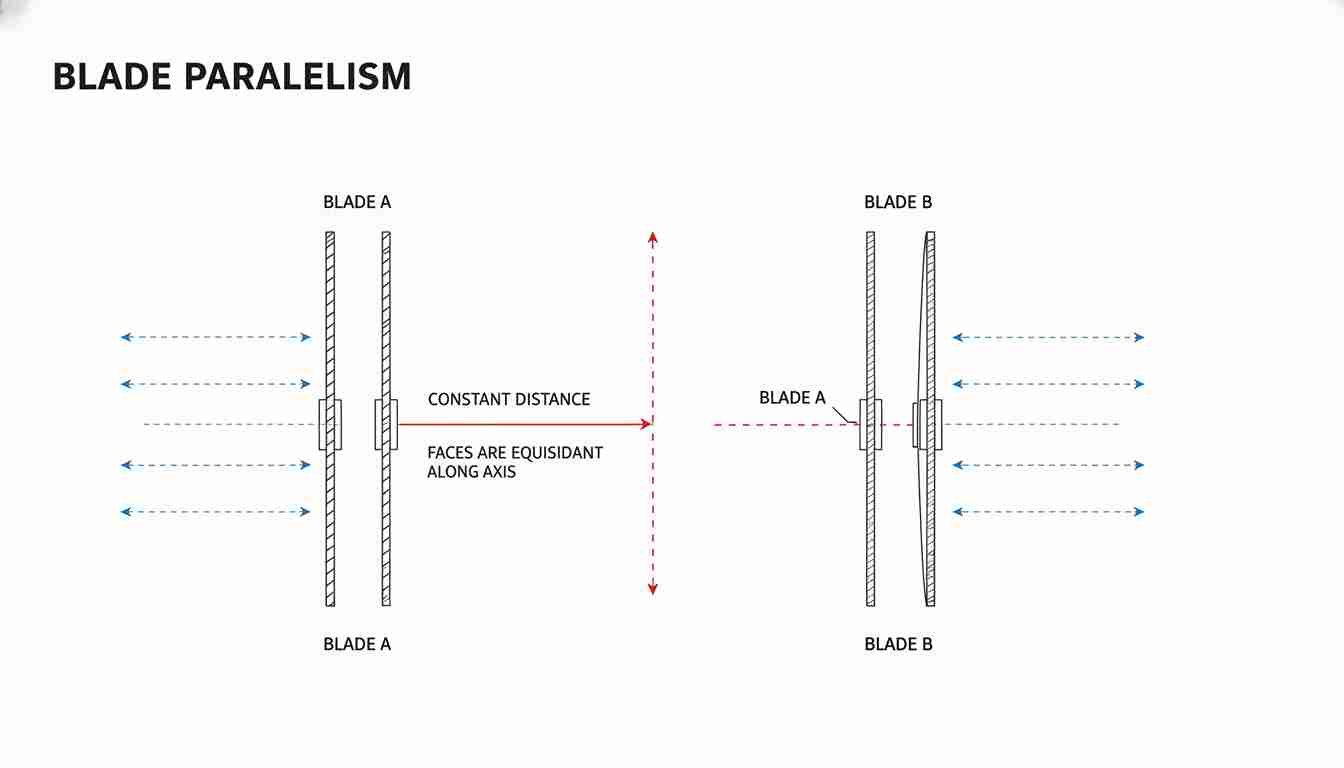

How Does Parallelism Affect Blade Performance?

Your blade faces might be flat, but are they parallel? Even tiny thickness variations cause vibration. This wears out the blade and machine bearings. Perfect parallelism ensures stability and extends tool life.

Parallelism ensures the blade has a uniform thickness across its entire body. This guarantees a consistent cutting gap5 and stable mounting. Poor parallelism leads to wobbling, uneven wear, and increased stress on both the blade and the machine's spindle.

Once we have two perfectly flat surfaces, we need to make sure they are perfectly parallel to each other. Think of it like the two rails of a train track. If they are not parallel, the train will wobble and eventually derail. A circular blade works the same way. If its two faces are not parallel, it becomes a microscopic wedge. When it spins, it will not run true. I worked with a customer in the metal foil industry in Mexico who had this exact issue. They were getting tiny burrs and uneven edges on their thin aluminum sheets. Their old blades were flat enough, but the parallelism was off. One side of the blade was thicker than the other. This created an unstable cutting action, ruining the edge quality of their product.

Parallelism Vs. Thickness

It's common to confuse parallelism with just "correct thickness," but they are different. A blade can have the correct average thickness and still have very poor parallelism.

| Feature | What It Controls | Impact of Failure |

|---|---|---|

| Parallelism | The geometric relationship between the two main faces. | Blade wobbles, unstable cutting gap, vibration, uneven wear. |

| Thickness | The overall dimension of the blade. | Determines if the blade fits the machine's holder correctly. |

This distinction is crucial. You could order a 3mm thick blade, and it might measure 3mm on average, but if one side is 3.1mm and the other is 2.9mm, its parallelism is terrible. We control parallelism to within a few microns, ensuring the blade is perfectly uniform. This stability is key to a clean cut and a long blade life.

Why Is Symmetry Critical For High-Speed Cutting?

Your machine vibrates excessively at high speeds? The cause is often an unbalanced blade. This asymmetry creates dangerous forces, damaging your equipment. A symmetrical blade ensures smooth, safe, and precise cutting.

Symmetry ensures the blade's mass is evenly distributed around its center axis. At high rotational speeds, even a minor imbalance creates significant centrifugal force. This force causes vibration, noise, and premature wear on bearings and spindles, making symmetry critical for safety and precision.

Symmetry is all about balance. Once a blade is flat and parallel, we must also ensure its mass and shape are perfectly balanced around its center. Think about the tires on your car. If they are not balanced, your steering wheel shakes at high speeds. A circular blade is the same, but the rotational speeds are much higher and the forces are far greater. An asymmetrical blade is a safety hazard and a maintenance nightmare.

The Chain Reaction Of Asymmetry

An unbalanced blade creates a cascade of problems that go far beyond a simple bad cut. The effects ripple through your entire machine, causing costly damage.This is not just about performance; it’s a critical safety and maintenance issue. That's why every industrial blade is checked for dynamic balance6. We ensure that symmetry is not an afterthought, but a core requirement for delivering a blade that is safe, stable, and ready for high-speed industrial use.

Conclusion

Flatness is the foundation. Parallelism ensures stability. Symmetry provides balance. All three must work together for a blade to deliver the precision, performance, and longevity your operation requires.

Understanding flatness is crucial for achieving consistent cuts and prolonging blade life. ↩

Explore how parallelism ensures stability and extends the life of your cutting tools. ↩

Learn how symmetry impacts safety and precision in high-speed operations. ↩

Understand how precision gauges ensure the quality and accuracy of blades. ↩

Learn why maintaining a uniform cutting gap is essential for quality cuts. ↩

Explore the importance of dynamic balance for safe and effective cutting. ↩