Struggling with blades that wear out too fast and make poor cuts? This problem costs you time and money. The right cutting fluid solves this by protecting your blades.

Cutting fluid plays four key roles: cooling, lubrication, cleaning, and rust prevention. It manages heat and reduces friction between the industrial blade and the material. This directly extends blade life1, improves cutting precision, and ensures a better surface finish on your final product.

When I talk to clients, cutting fluid is a topic that often comes up. Many people see it as just a simple coolant. But its role is much more complex and important. Understanding how it works is the first step to improving your cutting process. Let's explore the key functions that make it so essential for your operations.

How Does Cutting Fluid Improve Blade Life And Performance?

Are your blades overheating and failing prematurely? This leads to constant replacements and production delays. Proper lubrication and cooling are the answer to extending the life of your valuable tools.

Cutting fluid improves blade life by tackling two main enemies: heat and friction. The fluid cools the cutting zone, preventing the blade from softening or losing its sharp edge. It also creates a lubricating film that reduces wear, leading to longer-lasting blades and cleaner cuts.

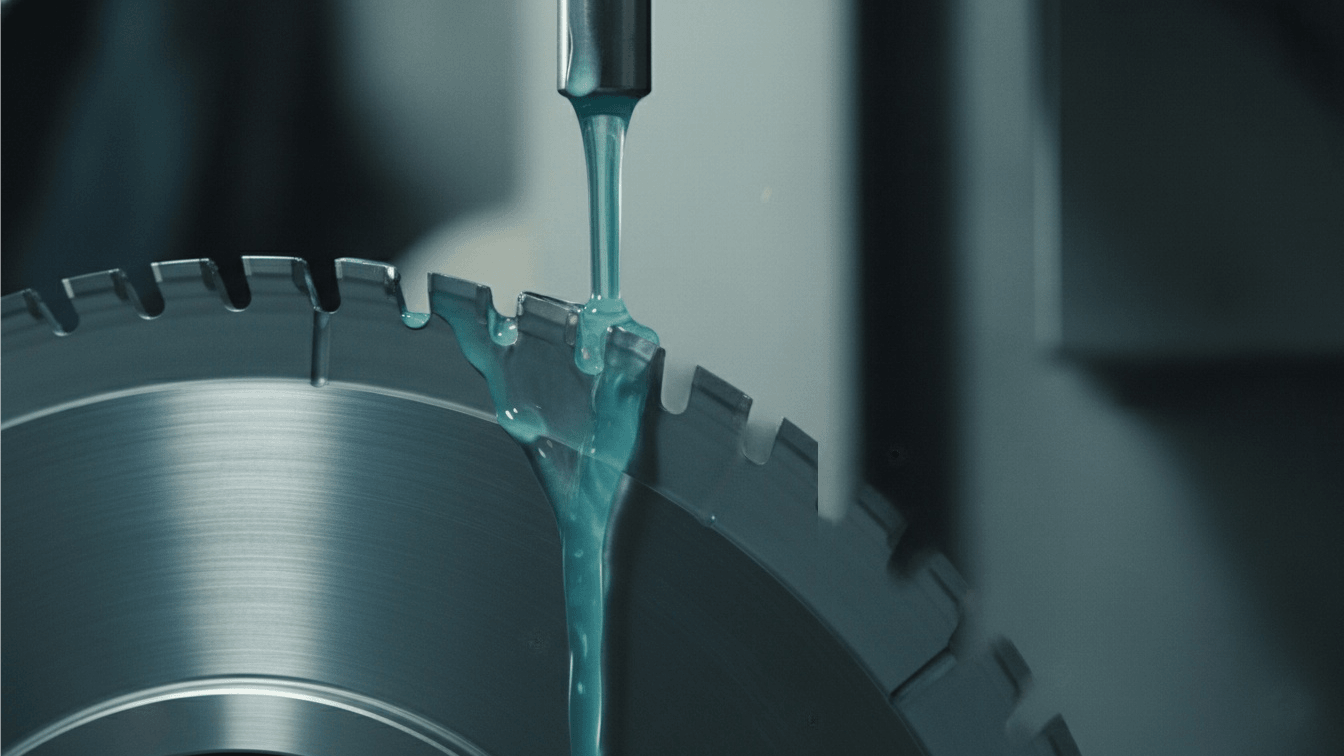

When a industrial blade cuts through material, it creates a huge amount of heat. If this heat isn't removed, the blade's edge can get too hot, become soft, and wear down very quickly. Cutting fluid flows over the blade and workpiece, carrying away this heat. This keeps the blade at a stable temperature, maintaining its hardness and sharpness for longer.

At the same time, there is massive pressure where the blade meets the material. This creates friction. Cutting fluid forms a thin, protective film between the blade and the material being cut. This film acts as a lubricant. It reduces friction, which means less force is needed to make the cut. This not only saves energy but also prevents tiny pieces of the workpiece from welding onto the blade's edge, a problem we call built-up edge. By preventing this, the blade makes cleaner cuts and lasts much longer. I remember a case with a paper converting client in Germany. They were slitting large paper rolls and their blades were dulling in just a few hours. The heat from the high-speed friction was burning the edges. We analyzed their process and recommended a switch to a high-performance synthetic coolant2 with special cooling additives3. The result was immediate. Their blade life more than doubled, which significantly cut their downtime and replacement costs. It showed how a simple change in fluid can make a huge difference.

What Are The Different Types Of Cutting Fluids And When Should You Use Them?

Confused by the many types of cutting fluids available? Choosing the wrong one can damage your blades and machinery. Understanding the main categories makes the selection process much simpler.

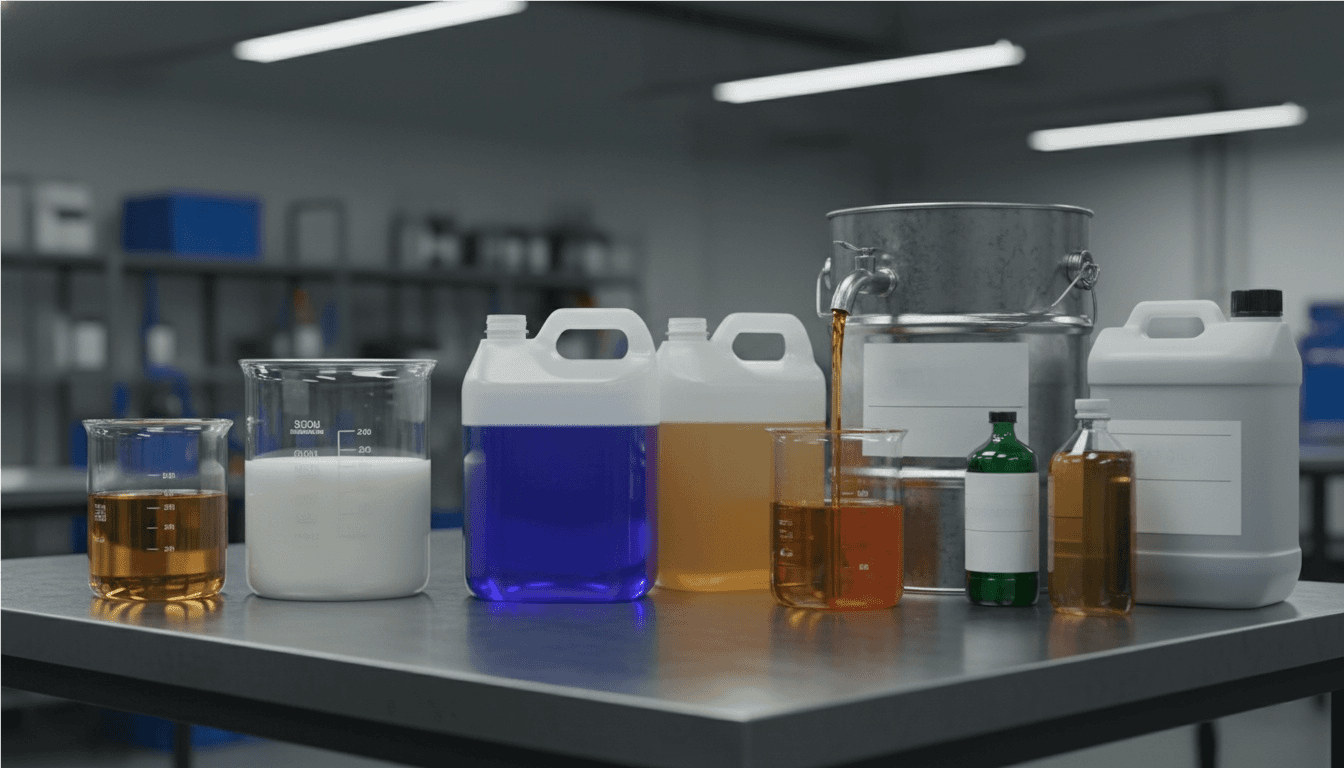

There are four main types: oil-based, water-soluble, semi-synthetic, and fully synthetic fluids. Oil-based fluids offer the best lubrication for heavy-duty cutting. Water-based and synthetic fluids provide superior cooling for high-speed operations. Your choice depends on the material, speed, and blade type.

Choosing the right cutting fluid is critical. It depends on your blade material, the workpiece, and the cutting speed. I always advise clients to consider these factors carefully.

Oil-Based Fluids

These are made from mineral oils and offer excellent lubrication. They are perfect for tough, low-speed jobs like shearing thick metal plates or deep-hole drilling where reducing friction is the top priority.

Water-Soluble Fluids (Emulsions)

Also known as soluble oils, these mix with water to form a milky emulsion. They offer a good balance of cooling and lubrication, making them very versatile for general machining.

Synthetic and Semi-Synthetic Fluids

Synthetics contain no oil and offer the best cooling performance, making them ideal for high-speed cutting where heat is the main issue, especially with carbide blades. Semi-synthetics are a mix, providing good cooling and better lubrication than full synthetics.

I worked with a metal fabrication company in Brazil that faced issues with their shearing blades chipping constantly. They were cutting thick stainless steel and the friction was immense. They were using a general-purpose water-soluble fluid that just wasn't providing enough lubrication. I recommended they switch to a heavy-duty, oil-based cutting fluid with extreme pressure additives. This provided the necessary lubricating barrier to handle the high forces. The blade chipping stopped, and their tool life increased by nearly 70%. This case highlights how matching the fluid type to the application is key.

Here's a simple table to help:

| Fluid Type | Primary Function | Best For |

|---|---|---|

| Oil-Based | Lubrication | Heavy-duty, low-speed cutting (e.g., shearing) |

| Water-Soluble | Balanced | General purpose machining |

| Semi-Synthetic | Cooling & Lubricity | Versatile, moderate to heavy cutting |

| Fully Synthetic | Cooling | High-speed cutting, grinding |

Are There Downsides Or Alternatives To Using Cutting Fluid?

Worried about the cost, maintenance, and mess of cutting fluids? You are not alone. These fluids are effective but come with challenges that can impact your workshop and budget.

Yes, there are downsides. Cutting fluids require maintenance to prevent bacteria growth, can cause skin irritation, and have disposal costs. Alternatives like Minimum Quantity Lubrication (MQL)4 or completely dry cutting5 are becoming popular, especially in industries where contamination is a major concern.

While cutting fluids are incredibly useful, they aren't without problems. They require careful management. If not maintained, bacteria and fungi can grow in the fluid, creating bad odors and potential health risks for operators. The fluid also needs to be filtered to remove chips and contaminants. Eventually, it must be disposed of, which has to be done responsibly and can be costly. These factors add to the total cost of operation.

Because of these challenges, some industries look for alternatives.

Minimum Quantity Lubrication (MQL)

MQL, also known as near-dry machining, uses a tiny amount of high-quality lubricant mixed with compressed air. It's sprayed directly at the cutting edge. This provides just enough lubrication while producing almost no waste.

Dry Cutting

In some cases, we can eliminate fluid completely. This requires special blades with advanced coatings that can resist high temperatures and reduce friction on their own. Dry cutting is the cleanest option and is often required in industries like food processing or medical device manufacturing. I recently helped a client in Australia who processes large plastic films for food packaging. They couldn't use any liquid coolants because of the risk of contaminating the product. We supplied them with a specialized tungsten carbide blade with a low-friction coating. This blade was designed to dissipate heat efficiently and operate without any fluid. The solution worked perfectly, ensuring product safety and eliminating all costs and maintenance related to cutting fluids. Choosing an alternative is a trade-off between blade life, cost, and process requirements.

Conclusion

Cutting fluid is essential for most cutting operations. It cools, lubricates, and extends blade life. Choosing the right fluid or a suitable alternative is key to achieving efficiency and precision.

Learn effective strategies to prolong the lifespan of your cutting blades and reduce replacement costs. ↩

Find out how high-performance synthetic coolants can enhance cutting efficiency and tool life. ↩

Learn about the role of cooling additives in enhancing the performance of cutting fluids. ↩

Discover how MQL can reduce waste and improve efficiency in machining processes. ↩

Understand the concept of dry cutting and its applications in industries requiring contamination control. ↩