Your industrial blades dull or chip too quickly, halting production. This downtime costs you time and money, a constant frustration. Micro-edge honing strengthens blades, giving them a much longer life.

Micro-edge honing is a precision process that slightly rounds a blade's sharp edge. This removes micro-fractures, strengthens the cutting point, and reduces stress. It makes blades more durable, improves cut quality, and extends their life, especially when cutting tough or abrasive materials.

This sounds simple, but the effect on performance is huge. A perfectly sharp blade seems ideal, but it's often too fragile for the heavy demands of industrial cutting. Let me share some real-world examples to show you exactly how this small change delivers big results.

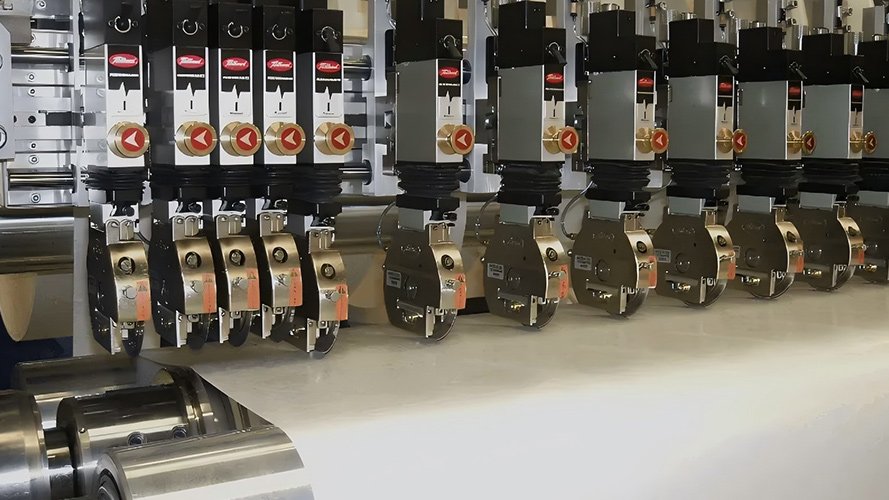

How Does Honing Increase Blade Durability And Reduce Machine Downtime?

Your blades are chipping, forcing frequent stops. This constant maintenance disrupts your workflow and hurts your output. What if a stronger edge could keep your machines running longer?

By rounding the sharp edge on a microscopic level, honing removes weak points and disperses cutting stress. This prevents chipping and cracking1, significantly increasing the blade’s lifespan. The result is less frequent blade changes2, reduced machine downtime, and more consistent production output.

A razor-sharp edge looks perfect, but under a microscope, it is a point of extreme stress. Any small impact concentrates all its force right on that tiny tip, causing it to chip or fracture. Micro-edge honing changes the geometry from a sharp "V" to a slightly rounded "U". This small change makes a huge difference. The cutting force is spread out over a larger surface area, making the edge much more robust and resistant to damage.

I remember a case with a packaging converter in Germany that we handled through online consultation. They were cutting heavy-duty corrugated board, and their standard blades were chipping every two to three hours. This meant stopping a high-speed production line. Based on the videos and data they sent us, we supplied them with custom blades featuring a specific micro-honed edge profile. The results were immediate. Their downtime from blade changes dropped by over 70%. It showed them that a strategically stronger edge is far more valuable than a simple sharp one.

Blade Edge Comparison

| Feature | Standard Sharp Edge | Micro-Honed Edge |

|---|---|---|

| Edge Profile | Microscopic V-Shape | Rounded U-Shape |

| Stress Focus | Concentrated at the tip | Dispersed along the curve |

| Common Failure | Chipping, micro-fractures | Gradual, predictable wear |

| Usable Lifespan | Short | Significantly longer |

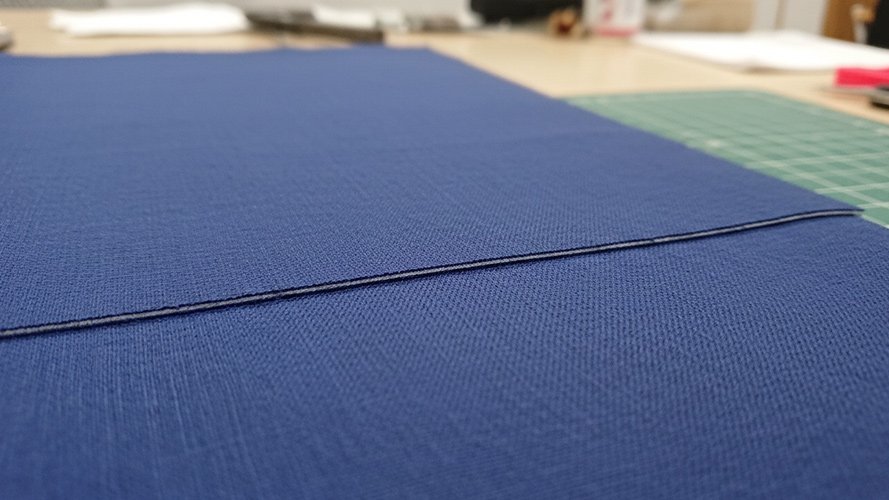

Can A "Duller" Honed Edge Actually Improve Cut Quality?

You need clean, precise cuts but your blades leave frayed edges or dust. It seems wrong, but an ultra-sharp blade is not always the answer. What if the secret to a cleaner cut is a stronger edge?

Yes, it absolutely can. An ultra-sharp edge is fragile and can develop micro-chips almost instantly. These chips then drag through the material, causing defects. A stable, honed edge maintains its perfect geometry for longer, resulting in consistently clean, smooth cuts without fraying or tearing.

The idea of a "duller" edge creating a better cut sounds strange, but it’s about stability. An extremely sharp edge is unstable. The very first cut can create microscopic damage. This damage gets worse with every cut, leading to poor quality. A honed edge is strong and stable. It resists deformation and damage, so it holds its ideal shape for thousands of cuts. This consistency is the key to high-quality results, especially with delicate materials like films, textiles, and nonwovens where any dragging or tearing is immediately visible.

A client in Vietnam manufacturing high-end sportswear described this exact problem to us during a video call. They used super-sharp blades to cut synthetic fabrics, but after a short run, the cut edges would look fuzzy and frayed. After analyzing their setup remotely, we introduced a blade with a very light hone. The edge was more robust and didn't chip. The result was a perfectly clean, sealed-looking cut, roll after roll. It completely solved their quality control nightmare.

Edge Stability And Cut Quality

-

The Problem with Ultra-Sharp Edges An overly sharp edge is brittle. It chips easily, and those tiny missing pieces create a rough, saw-like edge that tears fibers instead of slicing them.

-

How a Stable Edge Creates a Cleaner Cut A honed edge is smooth and strong. It holds its shape, parting the material cleanly and consistently without creating dust or frayed strands.

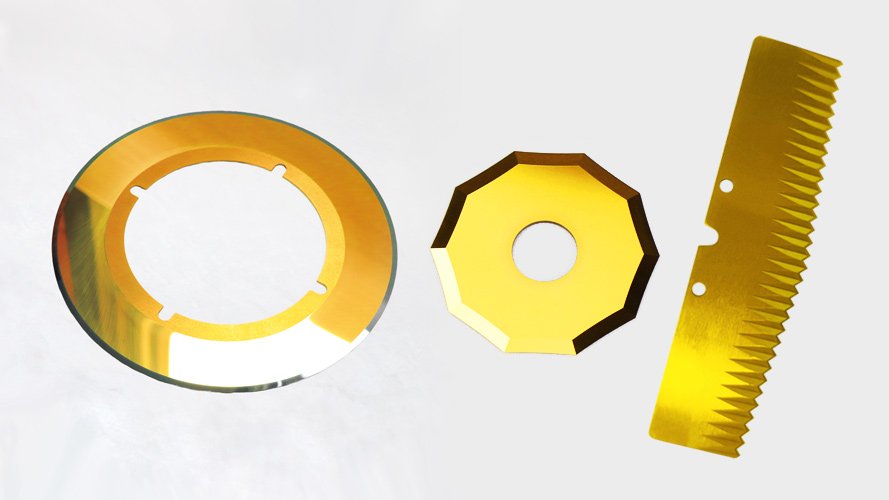

How Does Micro-Honing Make Blade Coatings More Effective?

You invest in expensive coated blades for better performance. But the coating flakes off at the cutting edge, wasting your money. There must be a way to make that investment last.

A razor-sharp edge provides a poor foundation for coatings, leading to peeling. Micro-honing creates a smooth, rounded surface that improves adhesion and provides support for the coating, preventing it from chipping away under pressure. A honed, coated blade lasts much longer.

Think of it like this: trying to paint the sharp point of a needle is difficult. The paint will be thin and chip off easily. But painting a small, smooth ball is easy, and the paint layer is strong and even. The same principle applies to blade coatings. A sharp edge is a point of high stress where the coating is at its thinnest and most vulnerable. Any impact can cause it to flake off.

We advised a plastic film producer in Mexico online who was using Titanium Nitride (TiN)3 coated blades. They showed us how the yellow TiN coating was chipping off the edge almost immediately. Our online guidance suggested preparing the edge with micro-honing before applying the coating. This small step was a game-changer. The coating adhesion was perfect, and the blade life4 more than doubled. It protected their investment.

Edge Preparation For Coatings

| Edge Preparation | Coating Adhesion | Durability of Coating |

|---|---|---|

| None (Sharp V-Edge) | Poor, flakes easily | Low |

| Micro-Honing (Rounded) | Excellent, strong bond | High |

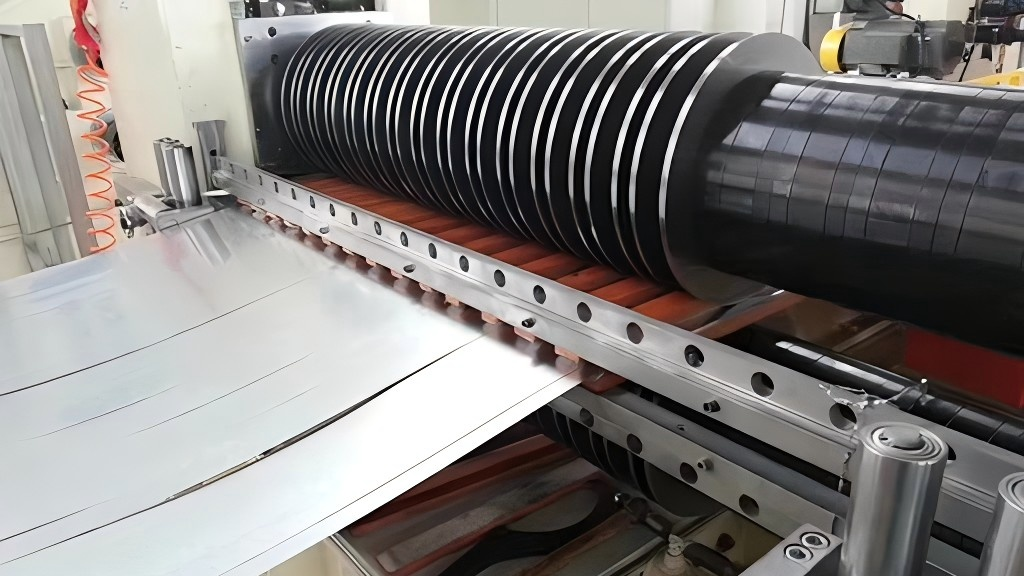

Can Honing Really Reduce Friction In High-Speed Cutting Operations?

Your machines run fast, but the blades get too hot. This causes material damage and rapid blade wear. You need a solution that can handle the speed and heat without compromise.

Absolutely. A smooth, honed edge glides through material with less resistance. A standard sharpened edge, on a microscopic level, has tiny burrs that create friction and heat. Honing removes these imperfections, resulting in a cooler, cleaner cut even at very high speeds.

Friction is the enemy of high-speed cutting. It generates heat, which can soften the blade's edge, cause material to stick to it, and even damage the product being cut. When a blade is sharpened, it often leaves behind microscopic burrs and a rough surface finish. These imperfections drag against the material, creating significant friction.

A large paper converter in Brazil reached out to us with this challenge. They explained how their slitting machines ran so fast that the blades would overheat and leave scorch marks on the paper rolls. After reviewing their setup via shared files, we provided them blades with a specific hone profile designed for lubricity. The smoother edge cut down friction, the blades ran cooler, the scorch marks disappeared, and they could finally maintain their high production speeds without sacrificing quality.

Sources Of Friction In Cutting

-

The Microscopic Source of Friction Tiny burrs, grit lines, and imperfections left over from the grinding process act like brakes, creating heat and drag as they move through the material.

-

A Cooler Cut for Better Quality A polished, honed edge has a lower coefficient of friction. It reduces heat buildup, prevents material from sticking, and helps maintain a sharp, effective cutting edge for longer.

Conclusion

Micro-edge honing is not about making a blade duller. It’s about making it smarter and stronger, leading to longer blade life, better cuts, and greater production efficiency.

Understand the common issues of chipping and cracking in blades and how to prevent them. ↩

Learn how fewer blade changes can lead to smoother operations and increased productivity. ↩

Discover the benefits of Titanium Nitride coatings and how they improve blade longevity. ↩

Find effective strategies to extend the life of your industrial blades through honing. ↩