Are your tungsten carbide blades failing unexpectedly? This downtime increases costs and disrupts your production schedule. Understanding the root cause, thermal fatigue, is the first step toward a solution.

Thermal fatigue in tungsten carbide blades is a damage process caused by repeating cycles of thermal stress. Rapid heating and cooling create surface stress, which forms micro-cracks. These cracks grow with each cycle, eventually leading to material spalling and complete blade failure.

This destructive cycle is a hidden enemy in many cutting operations, especially those involving frequent starts and stops. But once you understand how it works, you can take steps to fight back. This four-step process explains exactly how a perfectly good blade can fail from the inside out. Let's break down each stage to see precisely where the damage begins and how you can prevent it.

How Does The Initial Cut Create Stress On A Tungsten Carbide Blade?

You see the blade cutting, but an invisible force is also at work. This extreme heat creates massive stress on your blade’s surface, starting a process of silent damage.

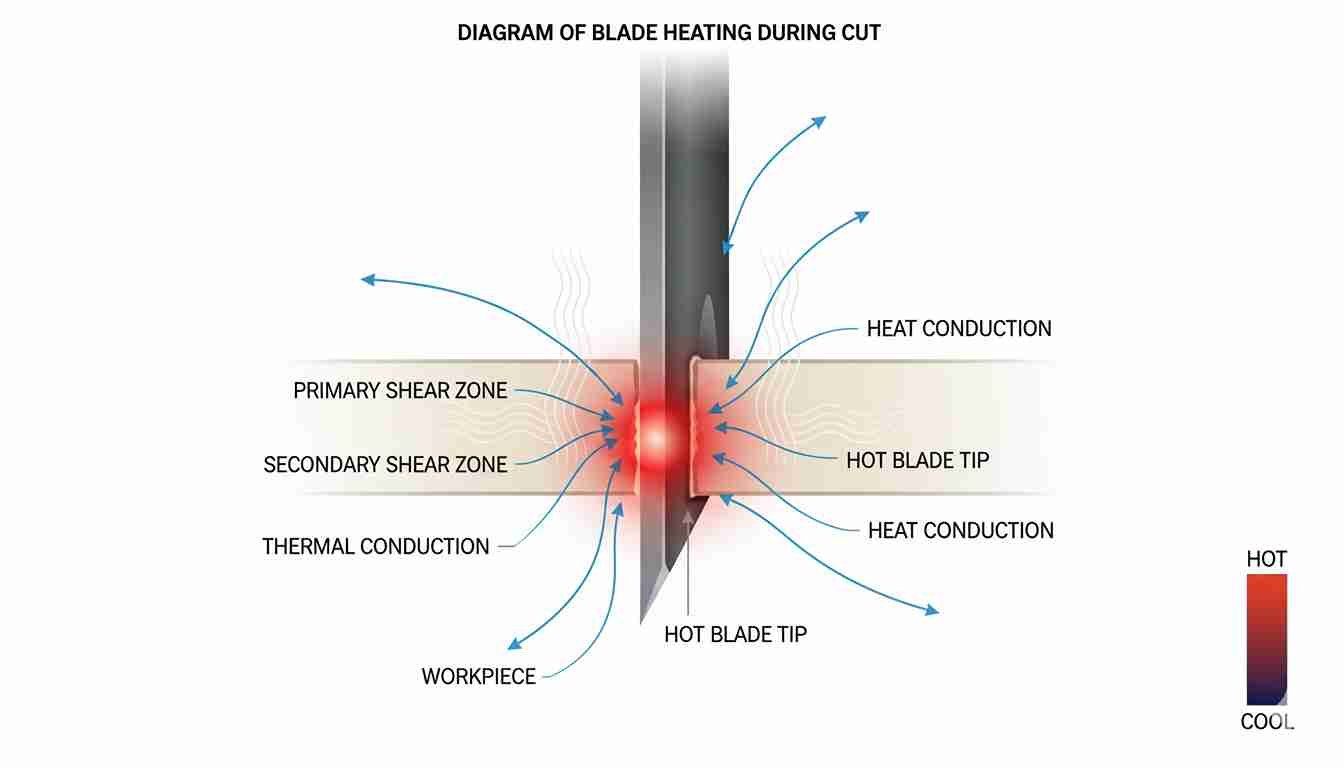

The initial cut generates immense stress when the hot chips, often reaching 800-1200°C, make contact. The tungsten carbide blade's surface expands rapidly from the heat, creating powerful compressive stress because the inner core of the blade remains cool and does not expand.

This first step is like a thermal shock. I had a client in the metal fabrication industry from the USA, who experienced this firsthand. His blades were failing much faster than expected during intermittent cutting of alloy steel. The problem wasn't the material he was cutting, but the cycle itself. Every time the blade engaged, its surface was subjected to an intense thermal load.

The Science Of Sudden Expansion

This process happens in a fraction of a second. The surface layer wants to grow due to the heat, but the cooler, stable core holds it in place. This creates a state of compression on the surface. Think of it as the surface trying to stretch, but being squeezed by the material underneath it. This internal conflict is the first step toward fatigue.

| Blade Section | Temperature | Material Reaction | Resulting Stress |

|---|---|---|---|

| Blade Surface | 800°C - 1200°C | Rapid Expansion | Compressive Stress |

| Blade Core | Relatively Cool | Remains Stable | No Significant Change |

This imbalance of forces puts a huge strain on the blade's microstructure from the very first cut.

Why Is The Cooling Phase Just As Damaging As Heating?

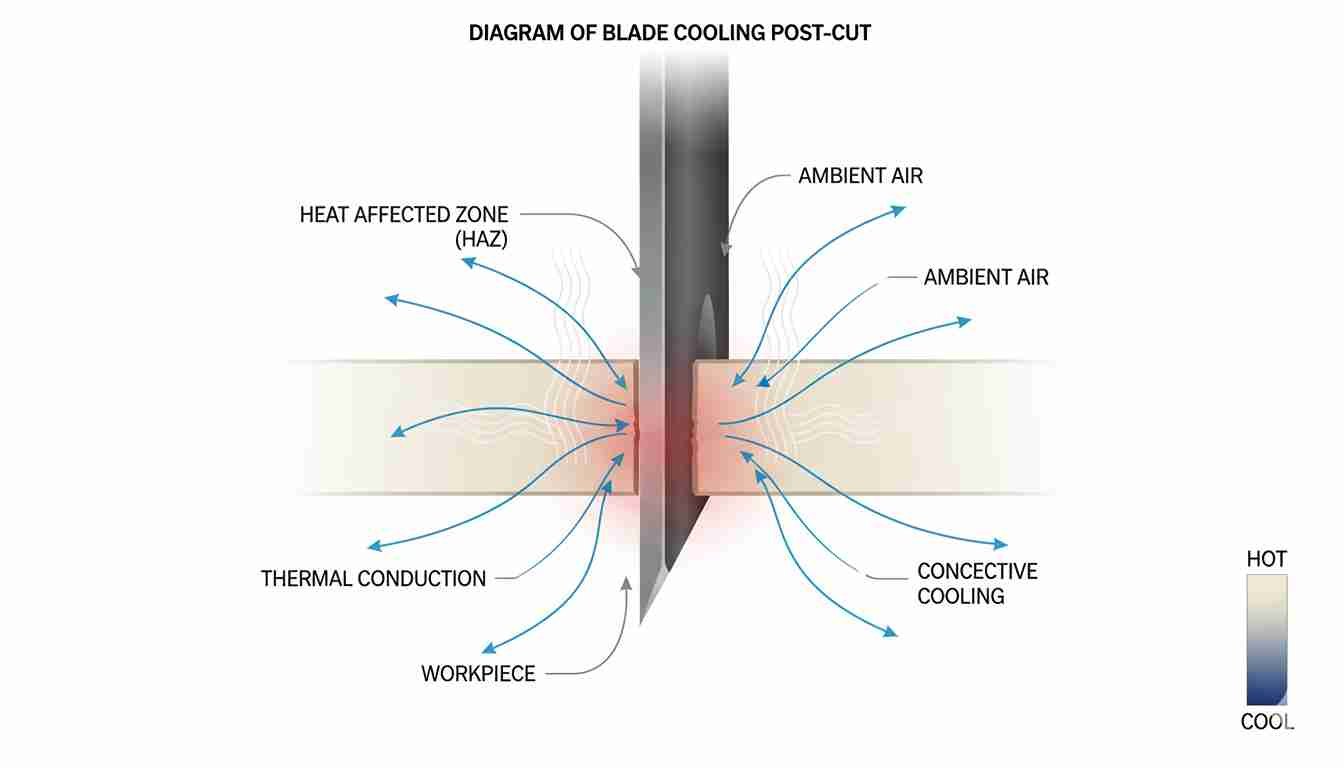

You might think the danger is over once the blade stops cutting. However, the rapid cooling that follows is just as destructive, introducing a new and opposite type of stress.

The cooling phase is damaging because the blade's hot surface shrinks rapidly when it meets air or coolant. This contraction is resisted by the still-warm core, creating immense tensile stress, or a pulling force, that tries to tear the surface apart.

The cycle flips from pushing to pulling. This reversal of stress is what makes thermal fatigue so aggressive. Our client's coolant application was very aggressive. He thought more coolant meant better performance, but it was actually accelerating the thermal shock. The sudden temperature drop was creating powerful tensile stresses on the blade's surface every time it disengaged from the workpiece.

The The Threat Of Tensile Stress

Tensile stress is the enemy of hard materials like tungsten carbide. While these materials are very strong under compression, they are more vulnerable to forces that pull them apart. Each cooling cycle is essentially a test of the material's breaking point. When the tensile stress repeatedly exceeds the material's inherent strength, tiny failures are guaranteed to happen.

| Cycle Phase | Action | Key Temperature Difference | Primary Stress Type |

|---|---|---|---|

| Heating | Blade cuts workpiece | Hot Surface / Cool Core | Compressive (Pushing) |

| Cooling | Blade leaves workpiece | Cooling Surface / Warm Core | Tensile (Pulling) |

This constant switch from a "push" to a "pull" on the material is the engine that drives thermal fatigue forward.

Where Do The First Cracks Begin To Form On The Tungsten Carbide Blade?

Your blade looks fine, but damage is already starting at a microscopic level. These tiny cracks are the direct result of the stress cycles we just discussed, forming in weak spots.

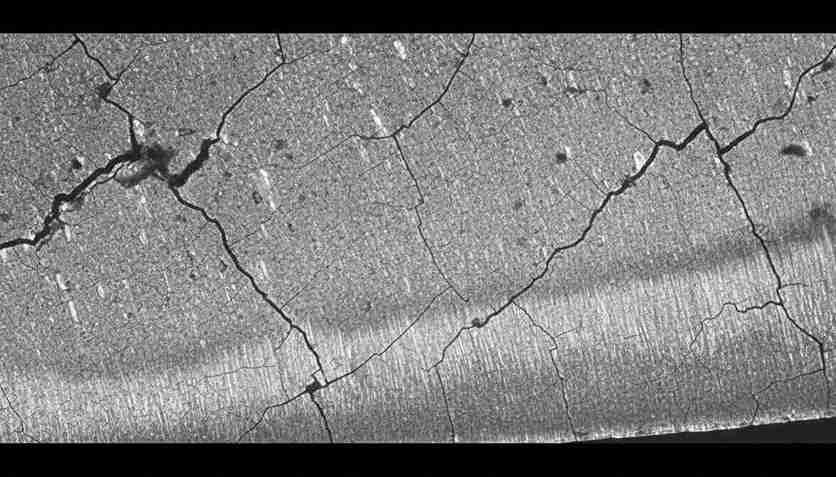

The first micro-cracks form in areas of high stress concentration on the blade's surface. These points, like grain boundaries or hard phase boundaries, are the first to fail under the repeated cycle of compressive and tensile stress, initiating the fatigue process.

This is the point of no return for the blade. Once these initial cracks, called fatigue cracks, are born, they will only grow. At PASSION, our material science team focuses heavily on creating a homogenous microstructure in our blades. This minimizes the number of weak points where cracks can start. A tungsten carbide blade with a less uniform internal structure is more likely to develop these initial cracks sooner.

The Birthplace Of Failure

Think of the blade's surface as a network of grains and binding materials. The boundaries between these components are natural points of stress. The alternating stress from heating and cooling acts like a tiny hammer, tapping on these boundaries over and over. Eventually, one of them gives way, and a micro-crack is formed.

Factors Influencing Crack Initiation:

- Material Quality: A more uniform and pure tungsten carbide has fewer weak points.

- Operating Temperature: Higher temperatures create greater thermal stress, accelerating crack formation.

- Cycle Frequency: More frequent heating and cooling cycles mean more opportunities for cracks to start.

Even a single micro-crack is a significant problem, as it creates a new, even weaker point for stress to concentrate on in the next cycle.

What Leads To The Final Failure Of The Tungsten Carbide Blade?

A single micro-crack seems harmless. But with each cutting cycle, these tiny flaws link up, creating a network of damage that ultimately leads to catastrophic failure and spalling.

The final failure happens as micro-cracks grow and connect with each other during repeated stress cycles. Eventually, this network of cracks penetrates deep enough to cause entire sections of the blade's surface to flake or break off, a phenomenon known as spalling.

This is the visible failure that stops production. The cracks that started invisibly had grown with each cut until they created a path of failure right through the material. Once a crack starts to propagate, it acts like a wedge, concentrating all the stress at its tip and driving itself deeper into the blade with every cycle.

From Crack To Catastrophe

The progression from a micro-crack to a failed blade is a predictable path. Each new cutting cycle adds a small amount of energy that extends the crack a little further.

Stages Of Crack Growth:

- Initiation: A micro-crack forms on the surface.

- Propagation: The crack grows deeper and longer with each stress cycle.

- Coalescence: Nearby cracks merge, forming a larger, more critical flaw.

- Fracture: The connected cracks reach a critical size, causing a piece of the blade to detach, leading to spalling and blade failure.

By recommending a tungsten carbide blade with superior toughness and a more controlled cutting process with less thermal shock to dramatically slow down this process and extend blade life significantly.

Conclusion

Understanding the four-step thermal fatigue cycle—heating, cooling, crack initiation, and propagation—is crucial. Recognizing this mechanism allows you to optimize processes and select better materials to extend blade life significantly.