Facing inconsistent cuts and frequent downtime? These issues hurt your bottom line. Rotary cutting offers a precise, efficient, and reliable solution to boost your production quality.

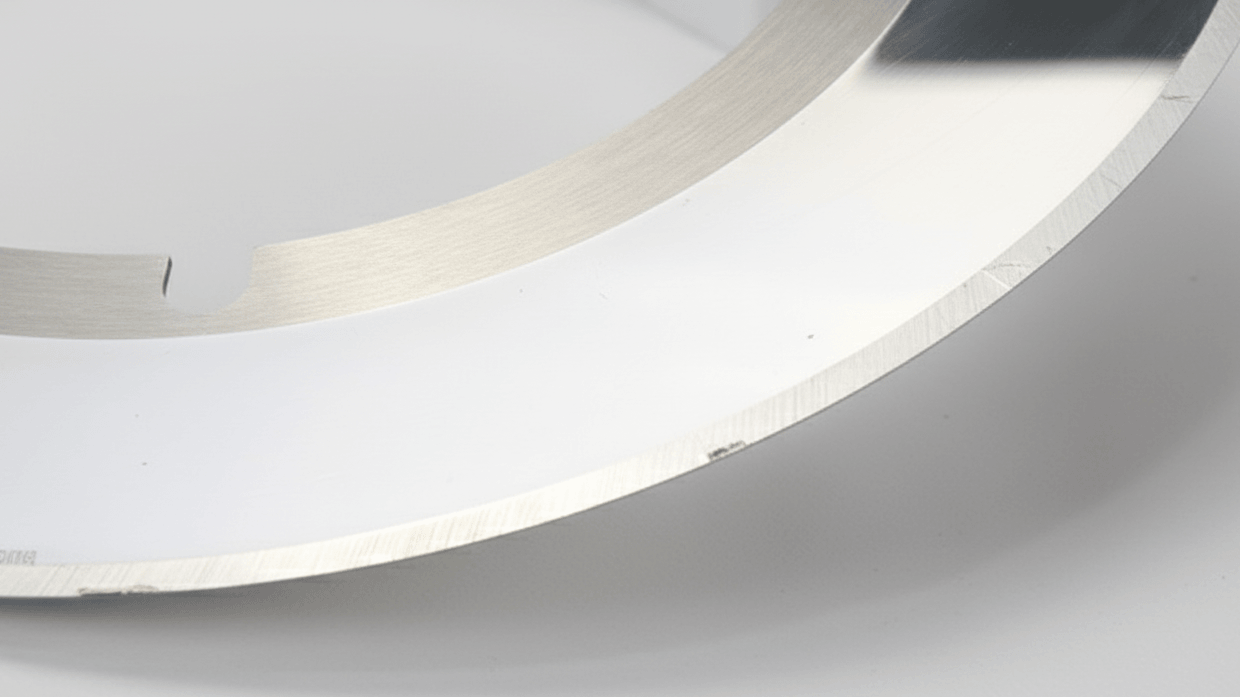

Rotary cutting blades work by using a continuous rotational motion to make line contact with the material. This method ensures smooth, high-speed cutting, distributes wear1 evenly for longer blade life, and produces exceptionally clean edges with minimal vibration or material waste.

This sounds simple, but the impact of this principle is huge. How does this simple rotational principle translate into such significant advantages across so many industries? Let's break it down. Let's explore the mechanics that make this technology a game-changer for modern manufacturing.

How Does The Rotational Motion Fundamentally Improve The Cutting Process?

Tired of changing blades constantly? Traditional cutting methods concentrate force and wear on one small point. Rotary circular blades work smarter, not harder.

The key is distributing the workload. Instead of a single point taking all the impact, a rotary blade uses its entire circumference. This continuous line contact reduces friction, heat2, and wear1, resulting in a cleaner cut.

The genius of the rotary blade is in its elegant and simple approach to a complex problem. Traditional reciprocating or straight blades attack the material with a direct impact, concentrating all the force and friction on a very small section of the cutting edge. This leads to rapid dulling and frequent replacements. Rotary cutting, however, completely changes the physics of the cut. I remember a client in Mexico running a large paper converting facility. They were frustrated with the downtime from changing their straight slitter knives multiple times a day. After we helped them switch to a rotary system, they went from changing blades every few hours to every few weeks. It completely changed their operational efficiency.

Point Impact vs. Line Contact

The fundamental difference lies in how the blade meets the material. A reciprocating blade operates with a series of impacts, which creates vibration and stress. A rotary blade glides through the material with a continuous shearing action.

| Feature | Reciprocating Cutting | Rotary Cutting |

|---|---|---|

| Contact Type | Point or short-line impact | Continuous line contact |

| Wear Pattern | Concentrated, rapid wear | Evenly distributed wear |

| Vibration | High | Minimal to none |

| Tool Life | Short | Exceptionally long |

| Cut Quality | Often rough, with burrs | Smooth and clean |

The "Self-Sharpening" Advantage

Another amazing benefit is what some call a "self-sharpening" effect. As the blade rotates, any microscopic wear is distributed evenly around the entire edge. This prevents any single point from becoming significantly dull, which helps the blade maintain a usable sharpness for a much longer period. It's not truly re-sharpening itself, but it’s the next best thing for maintaining consistent performance.

What Makes Rotary Blades The Superior Choice For High-Speed Production?

Is your production speed limited by your cutting blades3? Lagging cutters create bottlenecks and waste. Rotary blades are designed to keep up with the fastest production lines.

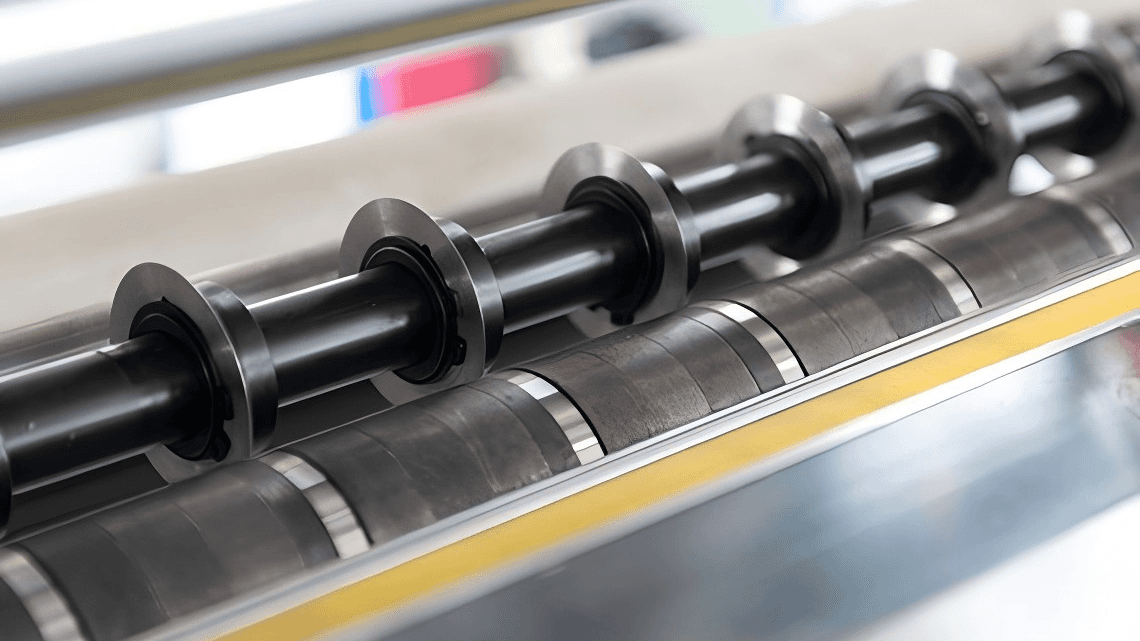

Rotary blades are built for speed. Their stable, continuous cutting action creates almost no vibration, unlike the start-stop impact of other methods. This stability allows for incredibly high linear speeds while maintaining perfect cut quality and protecting your machinery from excessive wear1.

In modern manufacturing, speed is everything. Production lines are constantly being pushed to run faster and produce more, and your cutting system can either be a booster or a brake. The low-vibration nature of rotary cutting is the main reason it can operate at speeds that would tear apart a reciprocating system. Because there is no back-and-forth impact, the blade and the machine remain stable, even when processing material at hundreds of meters per minute. This stability is not just about speed; it's also about protecting your investment in your equipment by reducing mechanical stress.

Unlocking Production Efficiency

When a production line has to slow down for the cutting station, it creates a bottleneck that affects the entire process. Rotary slitters can match the output speed4 of extruders, printing presses, and laminators, ensuring a seamless flow of production. This means you get more products made per hour, which directly improves your profitability. A partner of ours in Germany produces nonwoven materials for hygiene products. For them, dust creation during cutting was a huge contamination risk. The clean, shear cut from a rotary blade minimized airborne particles, helping them meet strict quality standards and improve the work environment, all while running at max speed.

Achieving Unmatched Quality

Speed is useless if the quality is poor. Fortunately, this is where rotary blades truly shine. The smooth shearing action produces a clean, perfect edge with almost no burrs, dust, or deformation. This is absolutely critical in many industries. In food packaging, a clean edge ensures a perfect seal to keep products fresh. In medical applications, a dust-free cut is essential for hygiene. The high-quality finish from a rotary cutter means fewer rejected products and a more reliable final result, which is something every plant manager wants to see.

Which Industries Benefit Most From Rotary Cutting Technology?

Struggling to cut challenging materials cleanly? From delicate films to tough composites, the wrong blade can ruin your product. Rotary technology offers precision for a wide range of applications.

Rotary cutting is vital in industries that demand precision and speed. Key sectors include flexible packaging, lithium battery manufacturing, nonwovens, paper converting, and rubber processing. Each relies on the clean, fast, and reliable slitting rotary blades provide.

The versatility of rotary cutting is one of its greatest strengths. I’ve had the opportunity to help clients across a huge range of sectors find the perfect rotary cutting solution. The core benefits—speed, precision, and longevity—are universally valuable, but they become absolutely critical in certain high-tech and high-volume applications. While the list of uses is long, a couple of key industries perfectly illustrate the power of this technology and its direct impact on product safety and quality.

Precision in Energy: Lithium Batteries

The electric vehicle and consumer electronics boom has put a huge focus on lithium battery manufacturing. Here, precision is not just a goal; it's a safety requirement. Battery electrodes are made of delicate foils coated with active materials. When these foils are slit into strips, any microscopic metal burr left on the edge can eventually pierce the separator film, causing a short circuit. A few months ago, I was working with a startup in the EV battery space. They were having major quality control issues with their electrode slitting. The burrs left by their old system were causing a high rejection rate. By implementing a high-precision rotary shear blade system, we eliminated the burrs, which dramatically improved their cell safety and production yield.

Flawless Finishes In Packaging

The flexible packaging5 industry is another area where rotary cutting is king. Materials like BOPP, PET, and various composite films must be slit with perfectly clean edges. Why? Because these slit rolls go on to printing, laminating, and finally, form-fill-seal machines. A jagged or deformed edge can cause tears during high-speed unwinding, lead to poor sealing, and compromise the integrity of the final package. For customers in this space, rotary slitting isn't just a process—it's the foundation of their product's quality and brand reputation.

Conclusion

The rotary blade's simple principle of continuous cutting delivers massive gains in quality, speed, and tool life, making it an essential technology for modern and demanding industries.

Understanding how evenly distributed wear enhances tool life can significantly improve your production efficiency and reduce costs. ↩

Understanding heat's impact on rotary cutting can enhance tool longevity and cut quality, crucial for efficient production. ↩

Learn about the latest cutting blades that can improve your production speed and quality. ↩

Understanding output speed is crucial for optimizing production efficiency and maintaining quality in manufacturing processes. ↩

Stay updated on the latest trends and technologies in the flexible packaging industry. ↩