Are you struggling with inconsistent or messy cuts on your corrugated boards? This common problem can lead to waste and production delays. The solution starts with understanding your tools.

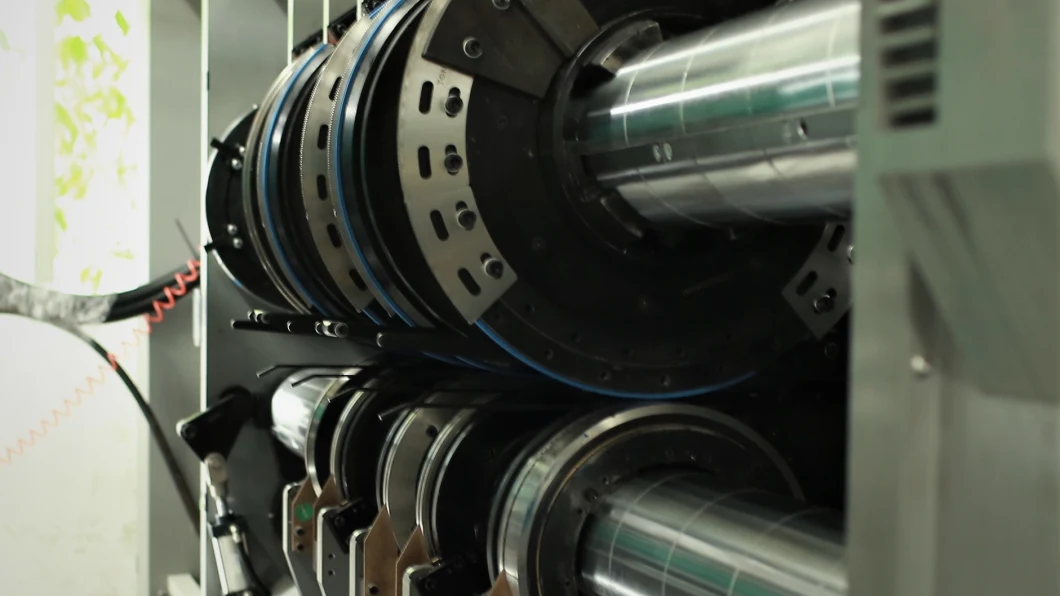

The working principle of a slotter knife is the relative rotational cutting motion1 between upper and lower blades2. As the board is fed through, these synchronized knives cut a clean, precise groove with a consistent depth, allowing for perfect folds and box construction.

I remember a client, Ethan, who was facing this exact issue. His machine was producing slots that were messy and inaccurate. After a quick call, we discussed how the slotter knives work. I explained that it's a team effort between an upper cutting blade and a lower support blade. The precision comes from the space between them. We sent him a set of our high-precision tungsten carbide slotter knives, and the a few days later he told me his production line had never run smoother. His experience shows that mastering the basics is the key to solving bigger problems. So, let's break down the details that make a perfect cut possible.

How Does Blade Gap Affect The Quality Of The Slot?

Are you seeing crushed edges3 or inconsistent slot depths on your boxes? The tiny space between your blades, the blade gap4, is likely the cause of your headaches.

The gap between the upper and lower slotter knives determines the cut's final quality. This gap must be perfectly adjusted based on the board's thickness and flute type to prevent crushing or incomplete cuts.

The blade gap is one of the most critical settings on a slotting machine. Think of it as a control dial for cutting quality. When you set this gap, you are telling the machine exactly how deep to cut. This setting is not a one-size-fits-all number. It needs to be changed based on the material you are running. A thick, double-wall board needs a wider gap than a thin, single-wall board. Getting this setting right is essential for a clean, functional slot. An incorrect setting can cause a lot of problems, which can halt your production and create a lot of waste. It’s a small detail with a huge impact on your final product.

The Impact Of An Incorrect Gap

The difference between a perfect slot and a defective one can be just a fraction of a millimeter. When the gap is not set correctly, two main problems can occur.

- Gap is too tight: If the space between the upper and lower blades is too small for the board's thickness, the blades will crush the paper fibers instead of cutting them cleanly. This not only weakens the board at the crease but can also physically damage the lower anvil roll, leading to expensive repairs.

- Gap is too wide: If the space is too large, the upper blade will not be able to cut completely through the paper fibers. This results in a shallow, messy cut with ragged edges and paper "hairs" being pulled. These messy cuts look unprofessional and can cause problems in automatic box assembly machines.

| Gap Setting | Result on Corrugated Board | Potential Issues |

|---|---|---|

| Too Tight | Crushed flutes, weakened board structure | Damage to the lower anvil, premature blade wear. |

| Just Right | Clean, sharp slot, perfect fold line | Optimal performance, increased production efficiency. |

| Too Wide | Ragged edges, fuzzy cuts (fiber pulling) | Poor box appearance, jams in automatic machinery. |

Why Is Lasting Blade Sharpness So Critical For A Clean Cut?

Are you tired of dealing with frayed edges and excessive dust on your machines? A dull blade is often the real problem, silently costing you time, money, and quality.

A sharp blade edge is essential for a clean cut. It slices through paper fibers effortlessly with minimal resistance. This action prevents tearing and creates a smooth, burr-free slot for perfect folding.

Imagine trying to cut a vegetable with a dull knife. You have to push hard, and you end up crushing it instead of slicing it. A slotter knife works the same way. The sharpness of the cutting edge is directly responsible for the quality of the cut. A sharp blade uses less force to cut, which puts less stress on the machine's motors and moving parts. This not only improves cut quality but also extends the life of your equipment and reduces energy consumption. It’s a win-win that starts with a perfectly sharpened edge.

How Sharpness Affects Performance

The condition of the blade's edge has a direct impact on the entire production process. It goes beyond just making a pretty cut; it affects machine health and operational efficiency.

- Clean Fiber Cutting: A sharp edge concentrates all its force on a very fine point. This high pressure cleanly severs the paper fibers. A dull edge, on the other hand, has a rounded surface. It tears and rips the fibers apart, which creates a rough slot and a lot of paper dust. This dust can build up in the machine, causing maintenance issues over time.

- Reduced Resistance: A sharp blade moves through the corrugated board with minimal friction. This means the machine's motor doesn't have to work as hard. The result is a smoother operation, lower electricity bills, and less wear and tear on the machine's drive system. It’s a simple factor that helps keep everything running smoothly.

What Materials Make The Best Slotter Knives?

Do your blades seem to wear out too quickly, forcing frequent replacements and downtime? Choosing the right blade material can dramatically increase its lifespan and maintain cutting performance for longer.

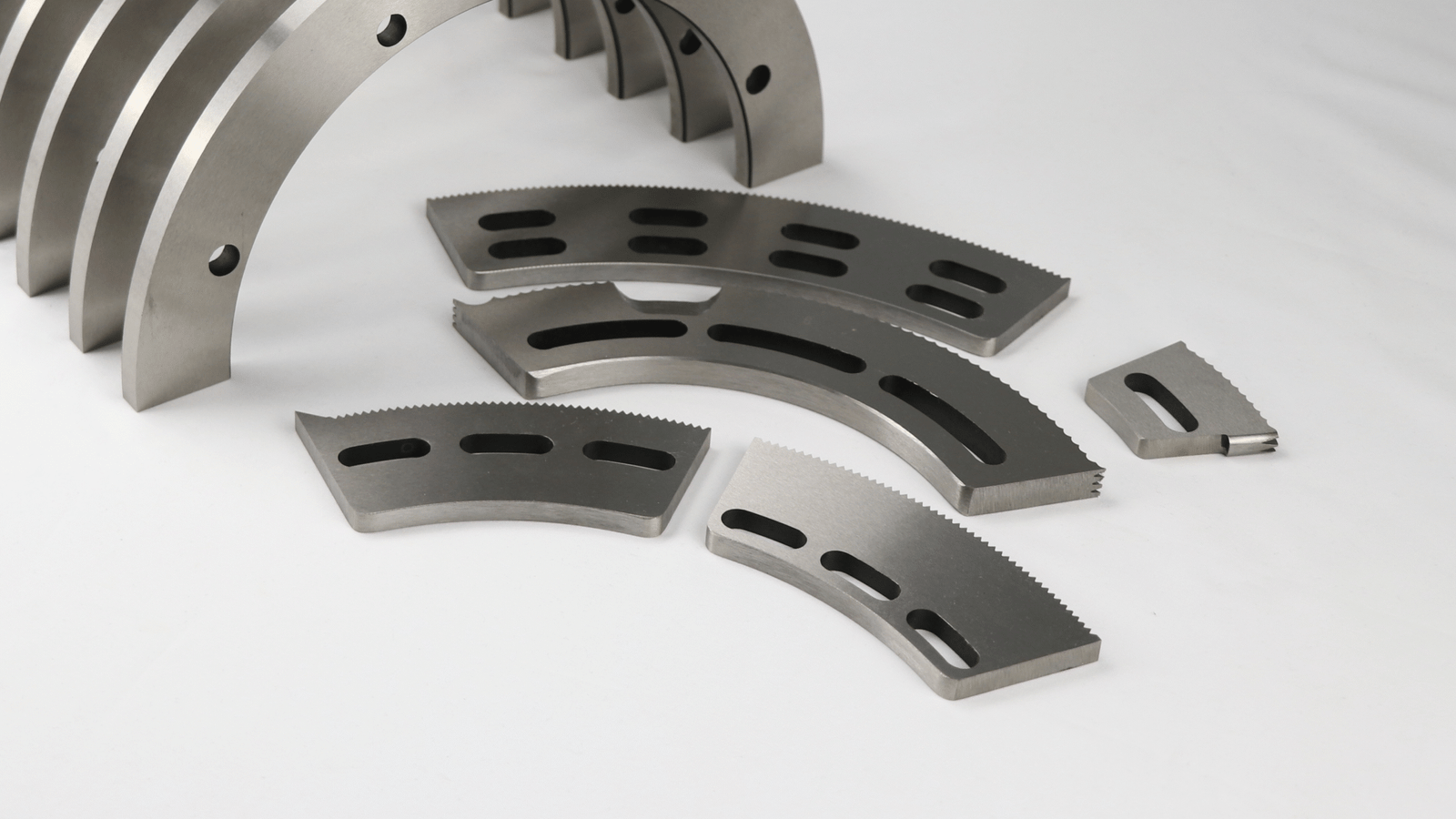

The best slotter knives are made from high-quality materials like D2 and SKD-11 tool steels5. These materials offer excellent wear resistance and the ability to hold a sharp edge for a long time.

The material of the blade is its foundation. It determines how sharp the blade can get and, more importantly, how long it can stay sharp. In our work, we've found that you can't compromise on material quality. A blade made from cheap, soft steel will become dull very quickly, forcing you to stop production for frequent blade changes. This is why we rely on proven, high-performance tool steels. For Ethan, who was dealing with very abrasive board material, we recommended tungsten carbide knives. This material is exceptionally hard and wear-resistant, making it perfect for tough jobs. While it's a bigger initial investment, the long-term benefit of fewer blade changes and consistent quality makes it a smart choice for many high-volume producers.

Comparing High-Performance Materials

Not all blade materials are created equal. The best choice for your operation depends on your production volume, the type of board you are cutting, and your budget.

- High-Carbon Tool Steel (D2, SKD-11): These are the workhorses of the industry. They contain high amounts of carbon and chromium, which creates a very hard and wear-resistant steel. They offer a great balance of toughness and edge retention, making them a fantastic choice for most corrugated board applications. They can be re-sharpened multiple times, offering a good service life.

- Tungsten Carbide: This is a premium material. It is a composite made of tungsten carbide particles held in a metal binder. It is much harder than tool steel and can hold its edge for an extremely long time, especially when cutting abrasive materials. The main trade-off is that it is more brittle, so it can chip if handled improperly, and it comes at a higher price point.

| Material | Key Feature | Best For |

|---|---|---|

| D2 / SKD-11 | High wear resistance, good toughness | High-volume, general-purpose corrugated cutting. |

| Tungsten Carbide | Extreme hardness, longest life | Demanding environments and abrasive board materials. |

Conclusion

In short, a slotter knife uses a rotational cut. A perfect result depends on a precise blade gap, lasting sharpness, and the right high-quality material for the job.

Learn about the cutting techniques that enhance the quality of your corrugated board cuts. ↩

Discover the importance of blade alignment for achieving clean cuts in production. ↩

Find out how to prevent common cutting problems that lead to waste. ↩

Explore how adjusting the blade gap can drastically improve your cutting results. ↩

Explore the advantages of these materials for high-performance cutting. ↩