Struggling with poor quality after slitting? Burrs, dust, and uneven edges can ruin your final product and increase waste. The key is to identify the root cause of these issues.

Common issues include burrs1, excessive dust2, uneven cuts3, and material deformation. These problems often stem from dull blades, incorrect blade gap4, poor tension control, or using the wrong type of blade for your specific material. Addressing these factors is key to achieving a clean, precise cut.

I often talk with clients who are frustrated by these exact problems. They invest in great material but get poor results. The good news is that most of these issues are preventable. It all comes down to the details of your cutting setup, especially the blades. Let's look at how we can fix this.

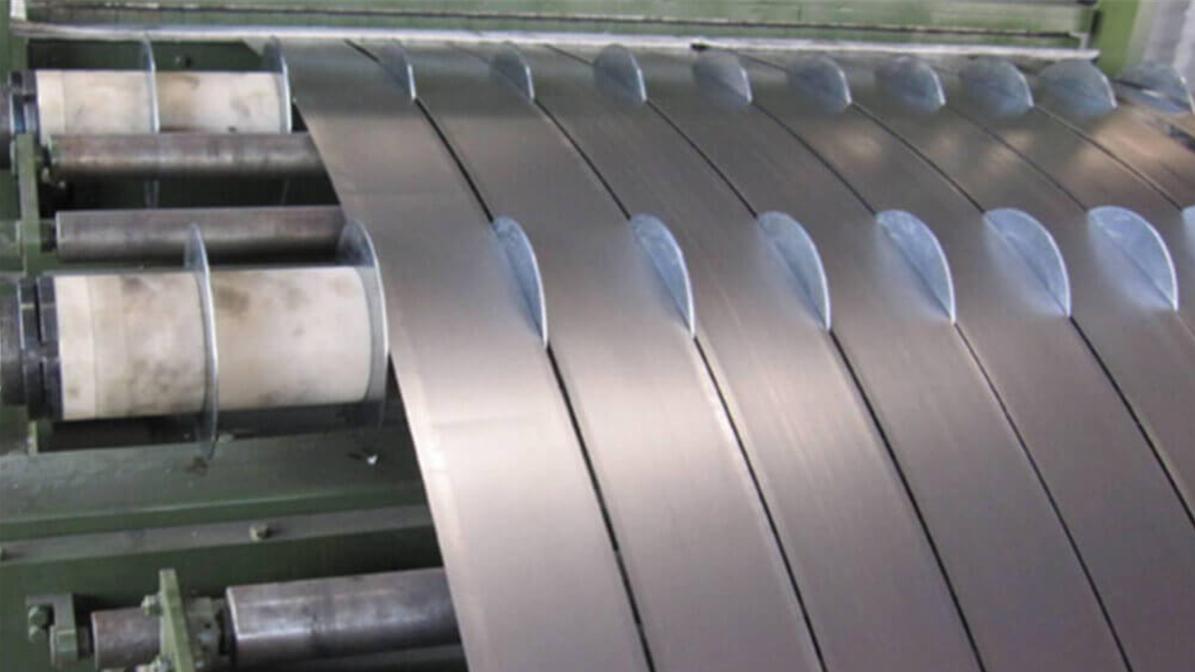

What Is The Role Of Blade Sharpness And Type?

Are your blades causing more harm than good? A dull or incorrect blade can stretch, tear, and create waste. The right, sharp blade ensures a clean cut every time.

Blade sharpness is critical. A dull blade fractures material instead of shearing it, causing burrs and dust. Also, the blade type must match the material. For example, razor blades work for thin films, while rotary shear blades are better for paper and thicker materials. It's not one-size-fits-all.

I remember a client, John from a packaging company in Germany, who was dealing with excessive dust when slitting thin films. His production line was constantly being stopped for cleaning. The problem was his blades. They were dull, which caused them to punch through the film rather than slice it cleanly. This fracturing action created tiny particles of dust. We helped him establish a regular blade sharpening schedule. A sharp blade cleanly shears the material, which drastically reduces dust and burrs.

The type of blade is just as important. You cannot use the same blade for slitting paper and slitting steel coil. The material properties dictate the best tool for the job.

Blade Selection Guide

| Material Type | Recommended Blade Type | Why It Works Best |

|---|---|---|

| Thin Plastic Films | Razor Blade | Provides a clean, scissor-like cut without stretching the delicate material. |

| Paper & Cardboard | Rotary Shear Blade | Offers durability and a smooth shearing action suitable for fibrous materials. |

| Metal Coils | High-Strength Alloy Blades | Designed to withstand high pressure and abrasion from hard materials. |

Choosing the correct, sharp blade is the first and most important step to solving many common slitting problems.

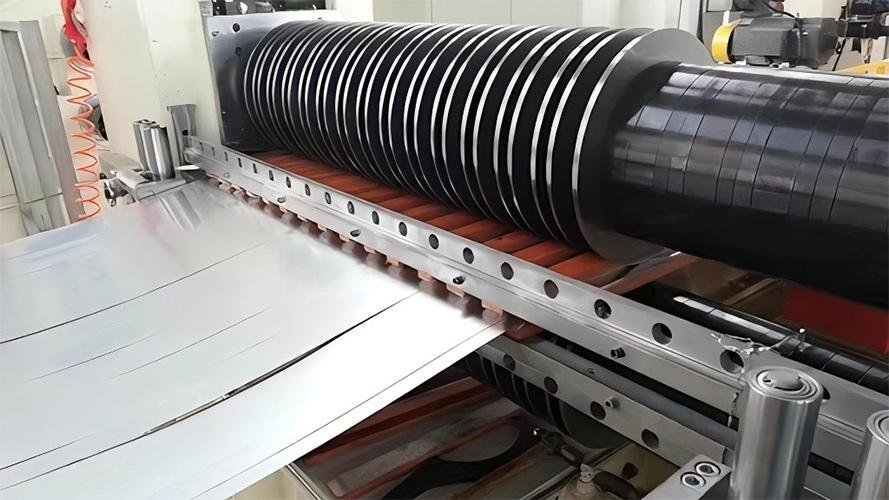

Why Is Blade Clearance And Overlap So Important?

Is your setup crushing or tearing your material? The wrong gap settings can cause wrinkles, burrs, and damaged edges. Perfecting clearance and overlap is essential for a flawless finish.

Blade clearance, the horizontal gap between blades, and overlap, the vertical intersection, control the cut's quality. Too much clearance tears the material, causing burrs. Too little crushes it. Incorrect overlap can lead to incomplete cuts or material stress, causing wrinkles and damage.

Many operators I've worked with think "tighter is better," but that's not always true. The ideal setup is a balance. The clearance should typically be a small percentage of the material's thickness. If the gap is too wide, the material gets pulled between the blades and tears, leaving a rough, burred edge. If the gap is too tight, the blades will pinch and crush the material, which can cause work hardening on metal edges or fractures in brittle materials.

Overlap is just as sensitive. If the blades don't overlap enough, they won't cut all the way through the material. This is a common cause of "angel hair," where thin, thread-like slivers of material are left behind. If they overlap too much, they create excessive pressure on the material near the cut, which can cause it to wrinkle or deform. The best way to find the perfect setting is through trial cuts before a full production run.

Understanding Setup Parameters

| Parameter Setting | Resulting Problem | How To Identify It |

|---|---|---|

| Clearance Too Large | Burrs, Rough Edges | The material edge feels fuzzy or has small slivers hanging off. |

| Clearance Too Small | Crushed Edges, Work Hardening | The edge looks shiny, compressed, and may have micro-cracks. |

| Overlap Too Small | Incomplete Cut, "Angel Hair" | The material isn't fully separated or thin slivers form. |

| Overlap Too Large | Wrinkling, Material Stress | The material shows signs of folding or buckling near the cut edge. |

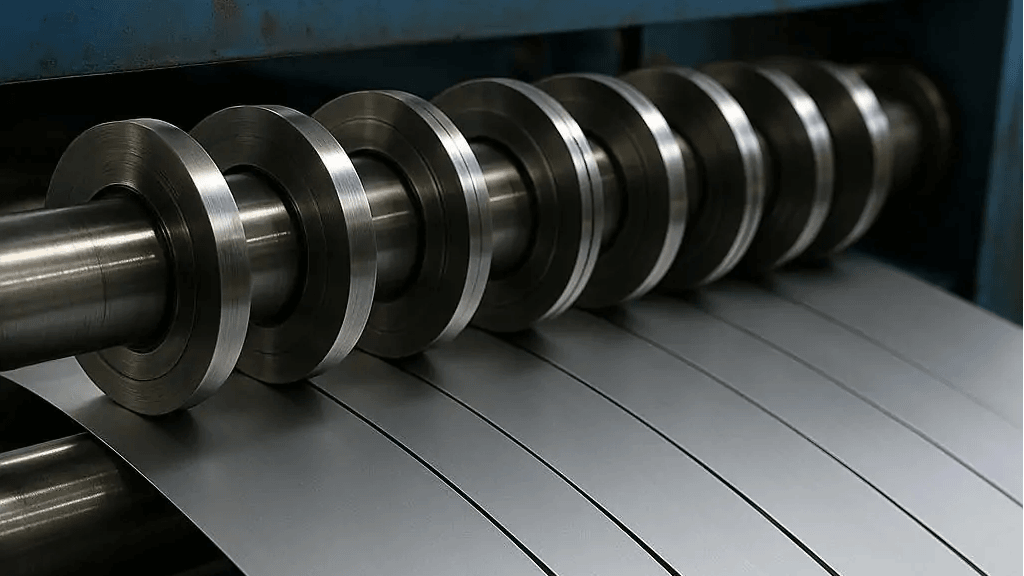

How Does Blade Precision Affect The Final Cut?

Are your slit widths inconsistent? Poor blade precision leads to wasted material and products that are out of spec. High-precision blades guarantee consistent, accurate results every time.

Blade precision, including concentricity5 and parallelism6, is vital for accuracy. If blades are not perfectly round or parallel, the gap between them will vary as they rotate. This leads to inconsistent slit widths, uneven edges, and potential material deformation, causing major quality control problems.

Think of concentricity like this: if a blade isn't perfectly centered on the shaft, it will wobble as it spins. This wobble changes the clearance and overlap with every rotation, leading to a wavy cut and inconsistent strip widths. I worked with a client in the textile industry, Maria, who faced this exact issue. Her fabric strips varied in width, causing problems in her next production step. The root cause was low-quality blades with poor concentricity. Once we supplied her with high-precision blades, the problem disappeared.

Parallelism is about how flat and parallel the blade faces are. If a blade is not perfectly flat, it will apply uneven pressure during the cut. This can cause the cut to be slanted instead of straight and leads to premature, uneven wear on the blade itself. Investing in blades with tight manufacturing tolerances is not a cost; it's an investment in quality and consistency.

Key Blade Precision Metrics

| Metric | What It Means | Impact If Incorrect |

|---|---|---|

| Concentricity | How perfectly centered the blade's hole is. | A non-concentric blade wobbles, causing inconsistent cut width and vibration. |

| Parallelism | How parallel the blade's faces are to each other. | Poor parallelism creates uneven pressure, leading to slanted cuts and blade wear. |

| Runout | The total wobble of the blade when mounted and rotating. | High runout results in wavy cuts and can damage machine bearings. |

Conclusion

To solve slitting issues, focus on three key areas: blade sharpness and type, correct clearance and overlap settings, and overall blade precision. Mastering these guarantees a better final product.

Understanding burr formation can help you prevent them and improve product quality. ↩

Learn effective strategies to minimize dust and enhance your production environment. ↩

Identifying the causes of uneven cuts can lead to better cutting techniques and improved results. ↩

Understanding blade gap can help you optimize your cutting setup for better results. ↩

Learn how concentricity affects cutting quality and blade performance. ↩

Understanding parallelism can help you select better blades for consistent cuts. ↩