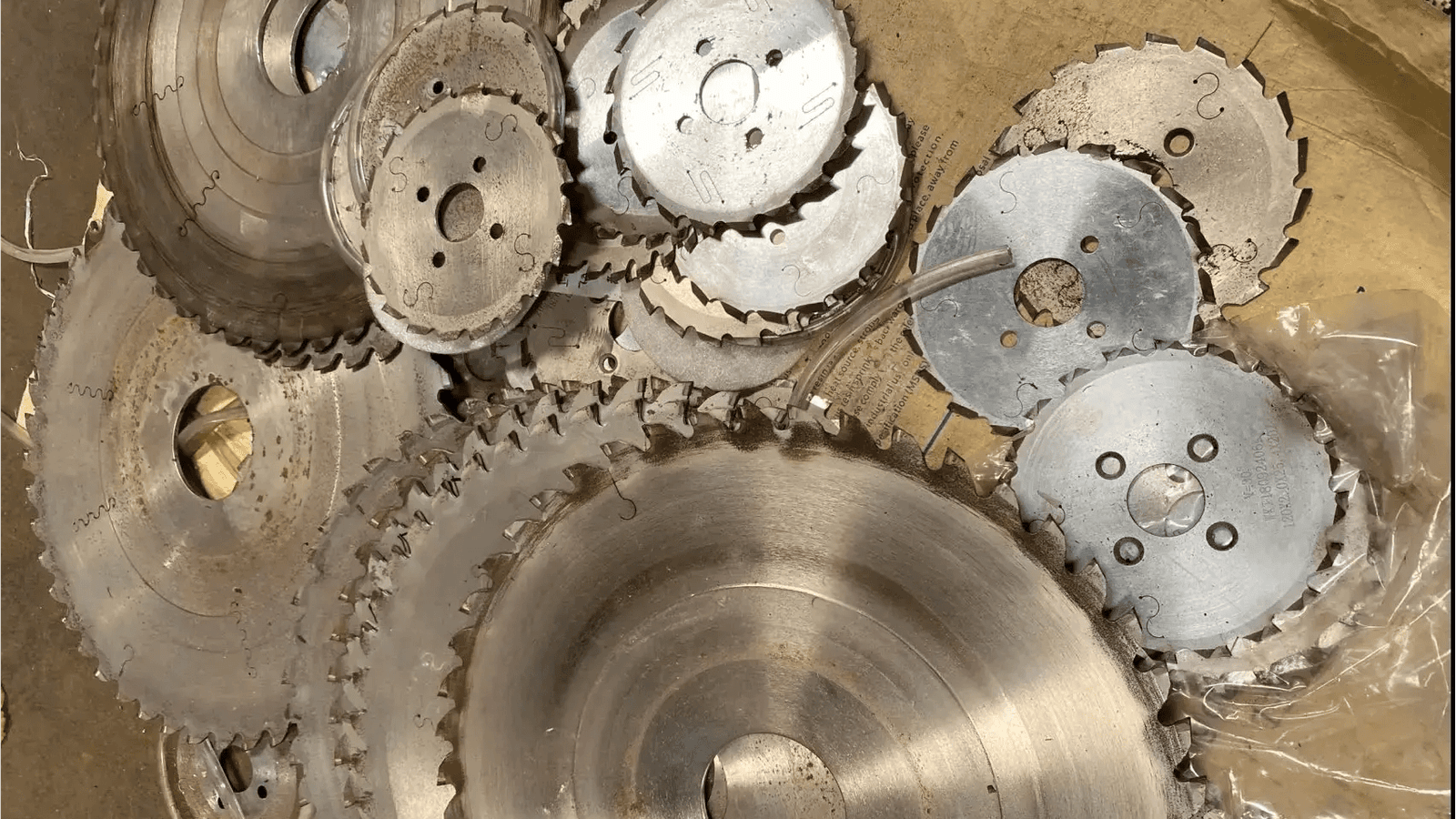

Stacks of used blades piling up? You are worried about waste and high replacement costs. Discover how recycling can turn old tungsten carbide into a valuable new resource for your business.

Discarded tungsten carbide blades are not waste. They are a rich source of valuable metals like tungsten and cobalt1. Through specialized recycling, these old blades are processed into new powder to manufacture high-performance cutting tools2 again, creating a sustainable and cost-effective loop for your business.

I have seen many companies treat their used blades as simple scrap metal. This is a big mistake. You are missing out on a huge opportunity. It is more than just waste management. It is a smart, strategic move for your business. Understanding the true value hidden in these discarded blades is the first step. It will change how you view your old tools. And it will open up new ways to save money and operate more sustainably. Let's look closer at why these old blades are so important.

What Makes Discarded Tungsten Carbide Blades So Valuable?

Tossing out old blades feels like throwing away money. You might suspect they are valuable but you are not sure exactly why. Let me explain the rare metals inside that make recycling so profitable.

The value comes from their material composition. Tungsten carbide blades are primarily made of tungsten and cobalt, both rare and expensive metals. Even after a blade is dull, these core materials remain intact and can be extracted and reused, retaining significant economic value for remanufacturing.

The secret to a blade's value is in what it is made of. It is not just steel. High-performance industrial blades are made from tungsten carbide, a composite material. This means it is a mix of different elements, mainly tungsten and cobalt.

The Core Components

Tungsten is an incredibly dense and hard metal. It gives the blade its strength and ability to hold a sharp edge even at high temperatures. Cobalt acts like a glue, or a binder. It holds the tungsten carbide grains together, providing toughness and preventing the blade from chipping or breaking under pressure. Both of these metals are rare and expensive to mine from the earth. Their unique properties are what make these blades perform so well in tough industrial cutting applications.

A Case From Brazil

I remember working with a large paper processing client in Brazil. They were using thousands of slitter blades every year and simply tossing the used ones into a scrap bin. They saw it as a disposal cost. I asked them to send me a few old blades for analysis. We created a report showing them the exact weight of tungsten and cobalt they were throwing away each month. The value was shocking to them. We helped them partner with a recycler. Now, that scrap bin generates a steady revenue stream for their facility. They turned a cost into a profit, just by changing their perspective on "waste".

How Are Old Tungsten Carbide Blades Actually Recycled?

Are you wondering how old, dull blades can become new again? The process might seem complex and mysterious from the outside. I will walk you through the simple, scientific steps that transform scrap into treasure.

The recycling process involves several key stages. First, blades are collected and sorted. Then, they are crushed into a fine powder. Following this, chemical processes like the zinc process or acid leaching separate the tungsten carbide and cobalt binder. The result is pure powder ready for new blade production.

Recycling tungsten carbide is a well-established industrial process. It is highly efficient and turns old tools back into high-quality raw material. The journey from a worn-out blade3 back to a usable powder is fascinating.

From Blade To Powder: The Journey

The process starts with collecting and sorting the blades to remove any contaminants. Then, the real work begins. The hard blades are put into powerful crushing machines that break them down into smaller pieces and then grind them into a fine powder. This powder is a mix of tungsten carbide and the cobalt binder. The goal is to separate these two valuable components. Specialized chemical methods are used to achieve this separation cleanly and efficiently, resulting in pure powders that are just as good as powders made from freshly mined ore.

| Step | Action | Outcome |

|---|---|---|

| 1. Collection | Gather and sort used carbide blades. | A pure batch of scrap material. |

| 2. Crushing | Grind blades into a fine powder. | Increased surface area for chemical reactions. |

| 3. Separation | Use chemical processes to dissolve binder. | Separated tungsten carbide and cobalt. |

| 4. Reclamation | Purify and process the materials. | High-quality tungsten and cobalt powders. |

Is Recycling Tungsten Carbide Blades A Global Trend?

Do you feel like you are the only one focusing on sustainability? You might be unsure if recycling industrial blades is a common practice for companies around the world. Let me assure you, this is rapidly becoming the standard for leading companies everywhere.

Yes, it is a major global trend. Leading industrial nations in Europe, North America, and East Asia have mature recycling systems. The push for green manufacturing and resource independence is driving more countries to adopt these practices, creating a global circular economy for tungsten carbide.

The shift toward recycling is not happening in just one or two countries. It is a worldwide movement. Companies are realizing that it is both good for the planet and good for their profits. This powerful combination is driving rapid adoption.

The Global Push For Sustainability

Many factors are pushing this trend forward. Governments are creating stricter environmental regulations. Customers are demanding more sustainable products from their suppliers. And companies themselves understand the risk of depending on a few countries for rare raw materials. Recycling provides a secure, local source of tungsten and cobalt. It makes the entire supply chain stronger and more resilient. This is a key reason why recycling has become a strategic priority for so many businesses. It is about building a more sustainable and stable future.

Mexico's Competitive Edge

A great example is a food processing client of mine in Mexico. They wanted to expand their exports to Europe and the United States. They knew their customers in those markets cared deeply about sustainability. I shared some reports with them showing how their European competitors were using blade recycling as a key part of their Corporate Social Responsibility (CSR) marketing. They immediately saw the opportunity. They started a recycling program and featured it prominently on their website and in sales presentations. It worked. It became a powerful tool that helped them win new contracts with large, eco-conscious international partners.

Why Should My Business Care About Recycling Blades?

Business costs are rising constantly. At the same time, environmental pressures from customers and regulators are growing. You need practical solutions that help both your budget and the planet. Let me show you how blade recycling delivers powerful economic and ecological benefits.

Recycling offers significant dual benefits. Economically, it reduces the cost of raw materials for new blades and can even generate revenue from scrap. Environmentally, it drastically cuts energy consumption and CO2 emissions compared to mining new tungsten, conserving natural resources and reducing your company's carbon footprint.

Thinking about recycling is not just about being "green." It is one of the smartest financial decisions a manufacturing business can make. The benefits directly impact your bottom line while also helping you build a better, more responsible company brand.

Saving Money and the Planet

The economic case is very clear. When you sell your used blades for recycling, you get money back for something you used to throw away. Also, using recycled materials to make new blades is cheaper than using virgin materials from a mine. This helps keep the prices of your new blades stable. On the environmental side, the benefits are even bigger. Mining and processing tungsten ore requires a massive amount of energy. Recycling uses far less energy, which means dramatically lower carbon dioxide emissions.

| Metric | Mining Virgin Ore | Recycling Blades |

|---|---|---|

| Energy Use | Very High | Up to 70% Less |

| CO2 Emissions | High | Very Low |

| Resource Impact | Depletes Natural Resources | Conserves Resources |

| Cost | Volatile & High | Stable & Lower |

How Can I Start A Blade Recycling System In My Facility?

You understand the benefits and you want to start recycling. But you might not know where to begin. The process can seem complicated or time-consuming. Here is a simple, step-by-step guide to get your system running smoothly and efficiently.

Establishing a system is straightforward. Start by designating a safe collection area for used blades. Partner with a reputable blade manufacturer4 or a specialized recycling company. They will guide you on sorting, storage, and logistics for pickup. Regular communication ensures the process is efficient and hassle-free.

Setting up a successful program is easier than you think. It is mostly about creating simple routines and working with the right partner. A little bit of organization upfront will create a smooth process that runs almost by itself.

A Simple 3-Step Plan

You can get started with these three basic steps:

- Designate & Educate: First, set up dedicated, clearly labeled, and safe collection bins in the areas where blades are changed. It is very important to train your staff on why this is being done and how to correctly segregate the used carbide blades from other scrap metal.

- Find a Partner: Next, contact your blade supplier. At PASSION, we often help our customers with this. You can also contact a certified local metal recycler. Ask them about their buy-back programs and what kinds of blades they accept.

- Establish a Process: Finally, work with your partner to agree on a regular collection schedule. This could be monthly, quarterly, or whenever you fill a bin. Make sure you understand their requirements for documentation and how and when you will be paid.

From Clutter To Cash In Thailand

I have a client in Thailand in the corrugated packaging industry. Their biggest complaint was the clutter and safety hazard from piles of old blades in their maintenance workshop. I helped them design a simple collection system. We provided them with special, heavy-duty bins for their cutting floor. Then, we connected them with a local logistics partner who picked up the bins quarterly. The workshop became safer and much more organized. Better yet, they turned a messy housekeeping problem into a new source of profit.

Conclusion

Recycling your discarded tungsten carbide blades is not waste disposal. It is a smart business strategy that saves you money, protects the environment, and builds a stronger, more responsible company.

Discover the economic significance of tungsten and cobalt in industrial applications. ↩

Find out what makes high-performance cutting tools effective and valuable. ↩

Learn about the fate of worn-out blades and their transformation in recycling. ↩

Get tips on selecting a reliable blade manufacturer for recycling partnerships. ↩