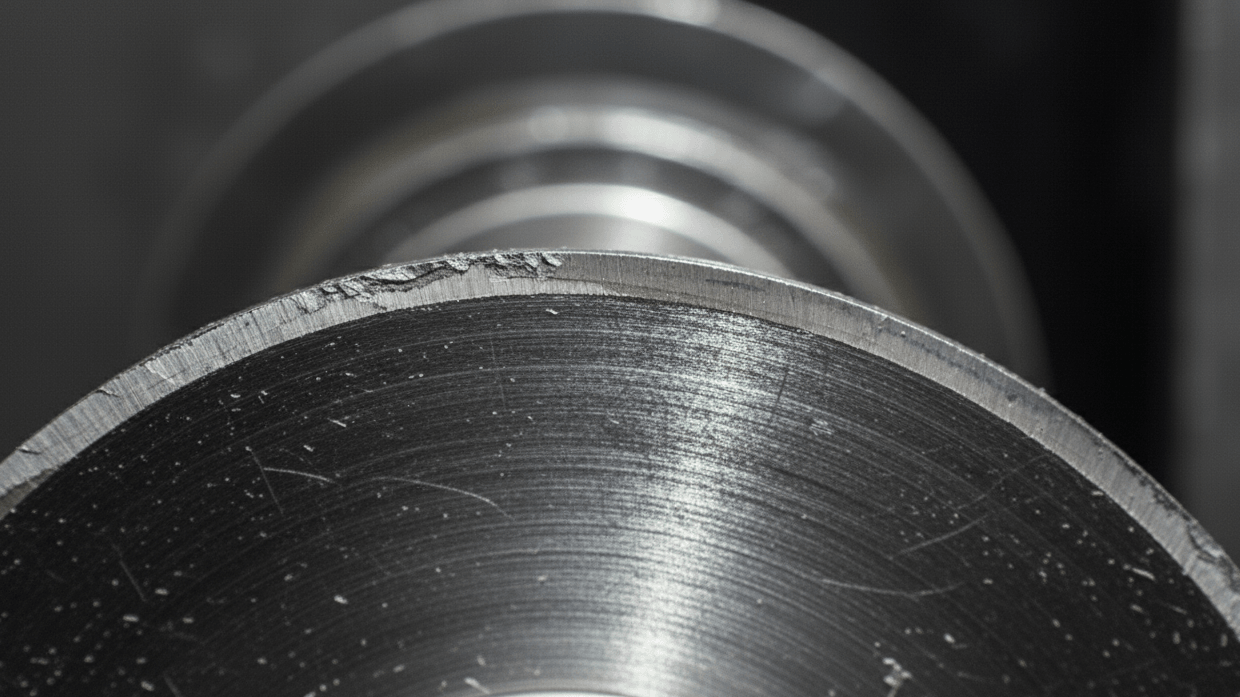

Your tungsten carbide knives keep chipping, causing downtime and waste. You invested in a tough material, but frequent failures are hurting production. The problem might be a blade angle1 that is too small.

An excessively small blade angle on a tungsten carbide circular knife makes the cutting edge too weak. This leads to frequent chipping, cracking, and a significantly shorter blade life. It also causes poor cut quality, like burrs and uneven surfaces, increasing your overall production costs.

Choosing the right blade is about more than just the material. I’ve seen many companies struggle with blade performance, and often, the issue lies in the small details of the blade's design. The geometry of the cutting edge is just as important as the grade of tungsten carbide you choose. Many factors contribute to blade performance, and the angle is one of the most critical. You might be wondering why your blades keep failing even when you buy the best. Understanding these details can save you a lot of time and money, so let's explore this further.

Why Do Tungsten Carbide Circular Knives Always Chip? Is It A Material Issue Or An Angle Issue? How Can I Determine The Cause?

You are frustrated with expensive blades chipping constantly. This costs you money in replacements and lost production time, and you are not even sure what the real problem is. Let's pinpoint the real cause.

Chipping in tungsten carbide knives is often caused by an incorrect blade angle rather than a material flaw. To find the cause, first check the blade angle. If it's too small for your application, it is likely the problem. If the angle is correct, then examine your material specs.

Tungsten carbide is extremely hard, but it is also brittle. I often tell my clients to think of it like glass—it resists wear exceptionally well, but it can shatter under the wrong kind of stress. An angle that is too small creates a very thin, sharp edge that lacks the structural support to handle the forces of cutting. During operation, your blade experiences friction, side pressure, and impacts. These forces concentrate on the weakest point: the cutting edge. If the angle is too acute, the edge simply can't take the pressure and chips away.

Distinguishing Between Angle And Material Issues

I remember a client, Adam, from a packaging company in Germany. His brand-new tungsten carbide knives were chipping within hours of installation. He was convinced the material we sent him was defective. I asked him to send photos and describe his process. He was cutting thick, recycled cardboard with a blade that had an 8-degree angle. The edge was just too fragile for the inconsistencies and pressure of that material. We redesigned a knife with a 12-degree angle. The chipping stopped immediately. It was a simple geometry fix that solved a major production headache.

You can often diagnose the issue yourself by looking at the blade.

| Symptom | Probable Cause: Angle Issue | Probable Cause: Material/Operational Issue |

|---|---|---|

| Micro-chipping along the edge | The blade angle is too small, making the edge too fragile for the cutting force. | High-frequency vibrations in the machine. |

| Large, irregular cracks | This is less likely the primary cause of a large crack. | An internal flaw in the carbide, or a sudden, severe impact (like hitting metal). |

| Edge rolling or deforming | This is not typical for small angle issues; it points away from it. | The carbide grade is too soft for the material being cut, or excessive heat is generated. |

| Consistent, predictable chipping | The blade angle is consistently too small for the standard operating pressure. | A machine setup issue, like improper blade alignment or excessive side pressure. |

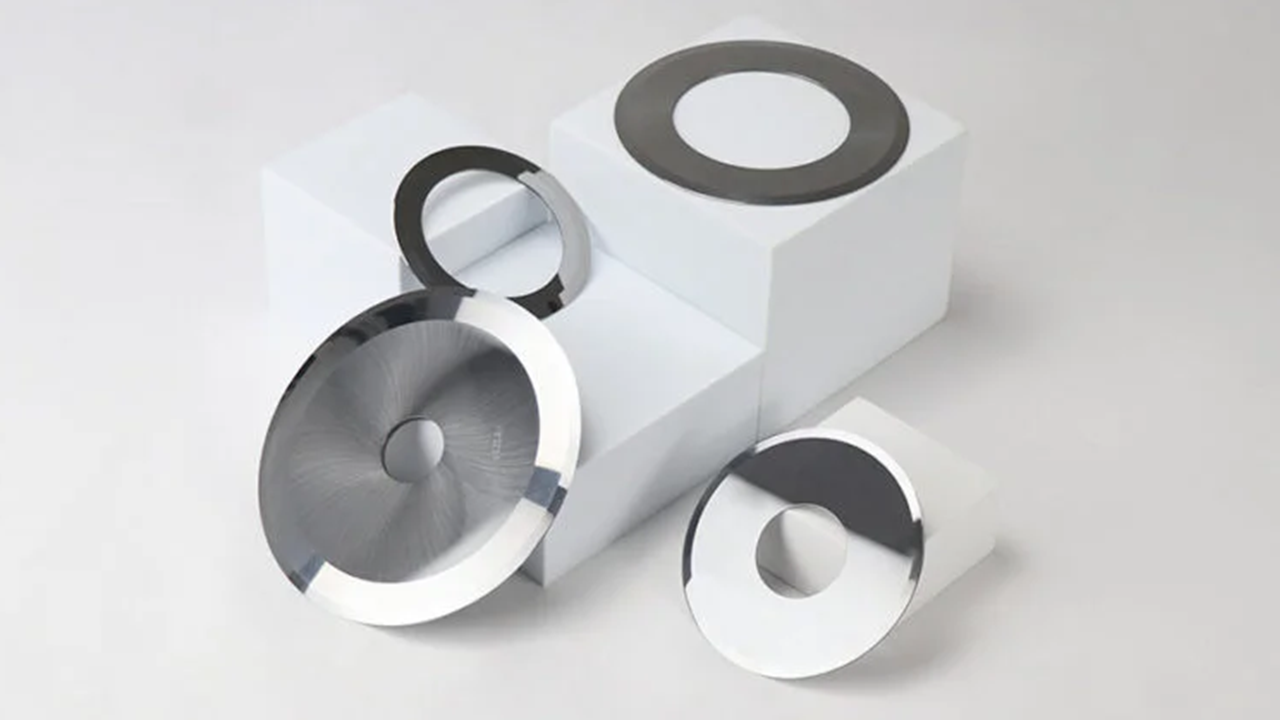

Can A Chipped Tungsten Carbide Circular Knife Be Reground? Will Regrinding Affect Its Performance?

You have a box of expensive chipped blades sitting in a corner. Throwing them away feels like a waste, but you worry that regrinding2 them will just make them weaker. Let me assure you, that is not the case.

Yes, a chipped tungsten carbide circular knife can usually be reground. A professional regrinding service removes the damaged material and shapes a new, sharp edge. If done correctly, regrinding will not hurt performance and can even improve it by applying a more suitable angle.

Regrinding is a standard practice that can save you a lot of money. It is much more than just simple sharpening. The process involves carefully removing enough blade material to get below any chips or micro-cracks, creating a fresh, undamaged surface from which to shape a new edge. We see regrinding as an opportunity to optimize your blade. If your original blade failed because of an incorrect angle, we can correct it during the regrinding process. This means you get back a blade that performs even better than it did when it was new.

The Regrinding Process

Quality regrinding requires specialized equipment. We use precision CNC machines with diamond grinding wheels to ensure accuracy and avoid overheating the blade. Overheating can create thermal stress and cause new micro-cracks, which will lead to failure.

- Inspection: We first inspect the blade to see how deep the chips are and if it can be saved.

- Rough Grinding: We remove the damaged material to create a clean foundation.

- Finish Grinding: We carefully shape the new cutting edge to the precise, optimized angle.

- Polishing: We polish the edge to ensure it is perfectly smooth for clean cutting and maximum life.

Impact on Performance

A professionally reground blade is essentially a new blade, just with a slightly smaller diameter. Its performance and lifespan will be restored to their full potential. The only risk comes from poor-quality regrinding services that might use the wrong equipment or rush the job. That is why working with a trusted blade manufacturer like us is so important. We understand the material and the geometry, ensuring you get a blade back that not only works but works better for your specific application.

How Do I Choose The Correct Blade Angle For My Application?

You know the angle is important, but you have no idea where to start. Guessing can lead to more broken blades, poor-quality cuts, and a lot of frustration. There is a logical way to find the perfect angle.

Choosing the correct angle involves balancing sharpness and strength. Start with the material you are cutting. Softer materials can use smaller angles for more sharpness. Harder materials need larger angles for more strength. Also consider your machine speed3 and cutting pressure4.

Finding the optimal blade angle is not guesswork; it’s a science that balances two competing needs: sharpness and durability. A smaller angle makes the blade sharper, which gives you cleaner cuts with less force. However, it also makes the edge weaker. A larger angle makes the edge stronger and more resistant to chipping, but it may require more force to cut and might not produce as clean of an edge. The goal is to find the "sweet spot" that gives you the best cut quality and the longest blade life for your specific situation.

Key Factors Influencing Blade Angle Selection

When I work with a new client, I always start by asking about their process. To recommend the right angle, I need to understand these key factors:

- Material Properties: Is the material soft like film, fibrous like textiles, or hard like plastic? Abrasive materials like fiberglass or recycled cardboard also require stronger edges.

- Material Thickness: Cutting a thin film requires a much different approach than slicing through a thick metal sheet. Thicker materials mean more force on the blade.

- Machine Speed and Impact: High-speed operations generate more heat and impact force. A clean shear cut is gentle on the blade, while a hard chop cut is very aggressive.

Here are some general guidelines we use as a starting point:

| Material Type | Typical Angle Range | Key Consideration |

|---|---|---|

| Soft Films, Thin Paper | 10° - 15° | Maximize sharpness for a clean cut without tearing. |

| Cardboard, Corrugated | 12° - 20° | Balance sharpness with strength to handle thickness and impurities. |

| Textiles, Non-wovens | 15° - 25° | Avoid material flagging and ensure a clean shear. |

| Hard Plastics, Metals | 20° - 35°+ | Prioritize strength and heat resistance to prevent chipping and premature wear. |

These are just starting points. The best way to find your perfect angle is to talk to an expert.

Conclusion

Selecting the right blade angle is crucial for tungsten carbide knives. It prevents chipping, extends blade life, and ensures high-quality cuts, ultimately lowering your production costs and boosting efficiency.

Understanding blade angle is key to optimizing cutting efficiency and reducing wear. ↩

Find out how regrinding can restore and enhance blade performance. ↩

Discover how machine speed impacts cutting efficiency and blade wear. ↩

Explore how cutting pressure influences blade wear and cutting efficiency. ↩