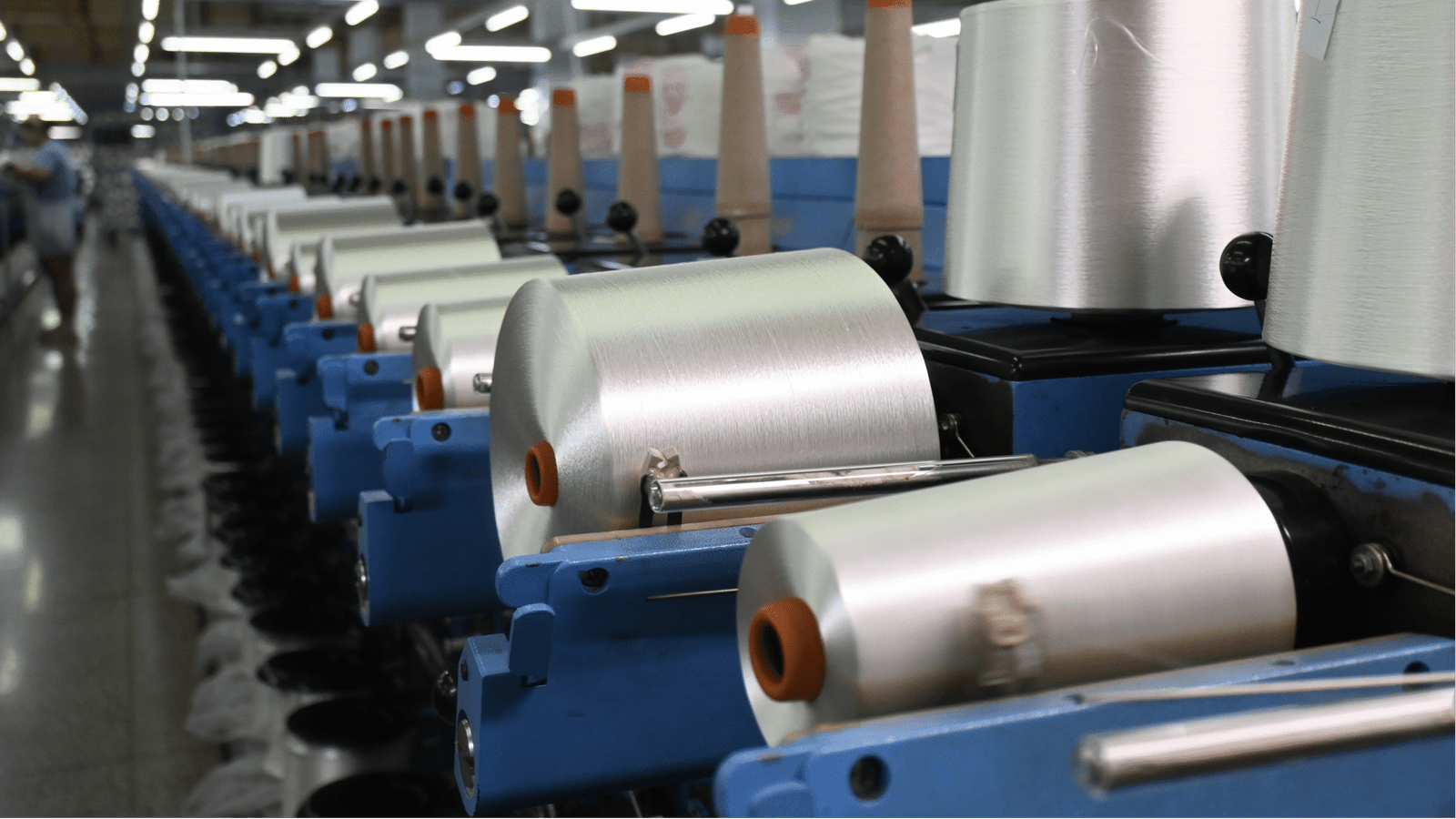

Cutting synthetic fibers causes constant tool wear and poor quality. This downtime and waste hurt your bottom line. The right tool selection makes all the difference.

When selecting tools, focus on four areas. Understand the fiber's unique properties. Choose the right blade material1, geometry, and coating2. Control the cutting process with proper cooling and static elimination. And ensure precise blade installation3 for consistent performance.

I talk with people in the chemical fiber industry every day. A common frustration I hear is how quickly their cutting tools fail. They invest in what they think are good blades, only to see stringing, melting, and rapid wear. This isn't just a tool problem; it's a process problem. But if we break it down, we can find a clear path to a solution. Let's look at why these fibers are so challenging to begin with.

Why Do Synthetic Fibers Wear Down Cutting Tools So Quickly?

Your new blades work great at first, but then dull quickly on synthetic fibers. This constant replacement cycle costs valuable time and eats into your profits. Let's understand why.

Synthetic fibers have four tough traits. High toughness resists clean cuts. Low thermal conductivity traps heat at the blade's edge. Melting sensitivity causes material to stick to the tool. And electrostatic sensitivity attracts abrasive dust, which accelerates wear.

When I help my customers troubleshoot, we always start here. Understanding these four core challenges is the key to finding a lasting solution. They all work together to make cutting difficult.

Four Key Characteristics

- High Toughness: Unlike materials that snap cleanly, synthetic fibers stretch and pull before they are severed. This action causes continuous abrasive wear on the cutting edge instead of a clean slice. It’s more like tearing than cutting, which is very hard on a blade.

- Low Thermal Conductivity: When you cut metal, a lot of heat escapes with the discarded chips. Synthetic fibers are great insulators, which means the heat generated during cutting gets trapped right at the tool’s edge. This leads to very high localized temperatures, very quickly.

- Melting Sensitivity: That intense heat is a big problem because these fibers melt at relatively low temperatures. The material turns into a sticky, viscous fluid that clings to the tool, forming what we call a built-up edge. This ruins the cut quality and increases the force needed to cut.

- Electrostatic Sensitivity: High-speed friction creates a lot of static electricity. This static charge acts like a magnet, pulling in dust and small particles from the surrounding environment. This speeds up tool wear and can also disrupt how the fiber material feeds into the machine.

| Fiber Characteristic | Impact on Cutting Tools |

|---|---|

| High Toughness | Prevents clean cuts, causing pulling and abrasive wear. |

| Low Thermal Conductivity | Traps heat at the cutting edge, leading to rapid temperature spikes. |

| Melting Sensitivity | Material melts and sticks to the tool, degrading cut quality. |

| Electrostatic Sensitivity | Attracts abrasive dust, accelerating tool wear and causing jams. |

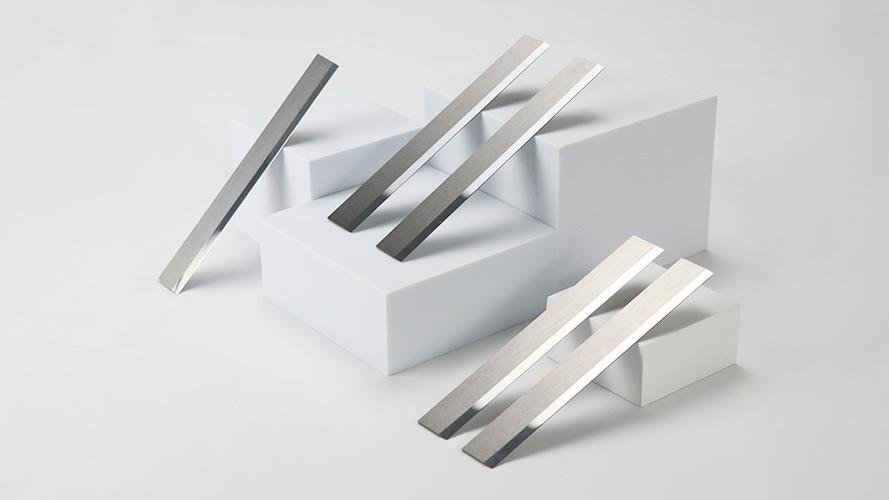

How Can the Right Tool Design Overcome Fiber Cutting Challenges?

Knowing the problems is the first step, but finding the right cutting tool is the real challenge. The wrong choice means you are back to constant wear and poor cuts.

The solution lies in precision design. Choose a fine-grain carbide substrate for a balance of hardness and toughness. Use a very sharp, polished edge to cut cleanly and reduce heat. Apply a specialized DLC coating to stop melted fibers from sticking to your blade.

At PASSION, we focus on engineering the entire tool, from the inside out. I once worked with a client whose PET fiber slitting line was struggling. They used standard high-speed steel blades and got terrible results—"whitening" and "adhesion" on the cut fibers. The root cause was heat. The steel blades couldn't handle the friction, and temperatures at the edge shot past 250°C, melting the fiber. We fixed it by focusing on these three areas.

The Right Material Matters Most

The foundation of a good tool is its material. For that client, we switched them to a fine-grain cemented carbide blade. Carbide's high wear resistance and ability to handle heat solved the melting issue immediately. It provides the perfect balance of hardness to resist wear and toughness to prevent chipping.

| Material Option | Best For | Downside |

|---|---|---|

| Fine-Grain Carbide | Balanced wear resistance and impact toughness. | Higher initial cost than steel. |

| Ceramic | High-speed cutting and abrasive materials. | Brittle, requires very rigid and stable machines. |

| Powdered HSS | Cost-effective needs and complex tool shapes. | Lower heat and wear resistance than carbide. |

Smart Geometry for a Cleaner Cut

The shape of the cutting edge is just as important. We use large front angles and extremely sharp edges. This design reduces the force needed to cut, which means less material deformation and less heat generated in the first place. We also polish the edge to a mirror finish to reduce friction and give melted material nothing to hold onto.

A Protective, Non-Stick Coating

Think of a coating as a non-stick pan for your tool. For synthetic fibers, a Diamond-Like Carbon (DLC) coating is the best choice. It has an incredibly low friction coefficient and is chemically inert, so the melted fiber simply doesn't stick. This prevents built-up edges and keeps the cut quality high for much longer.

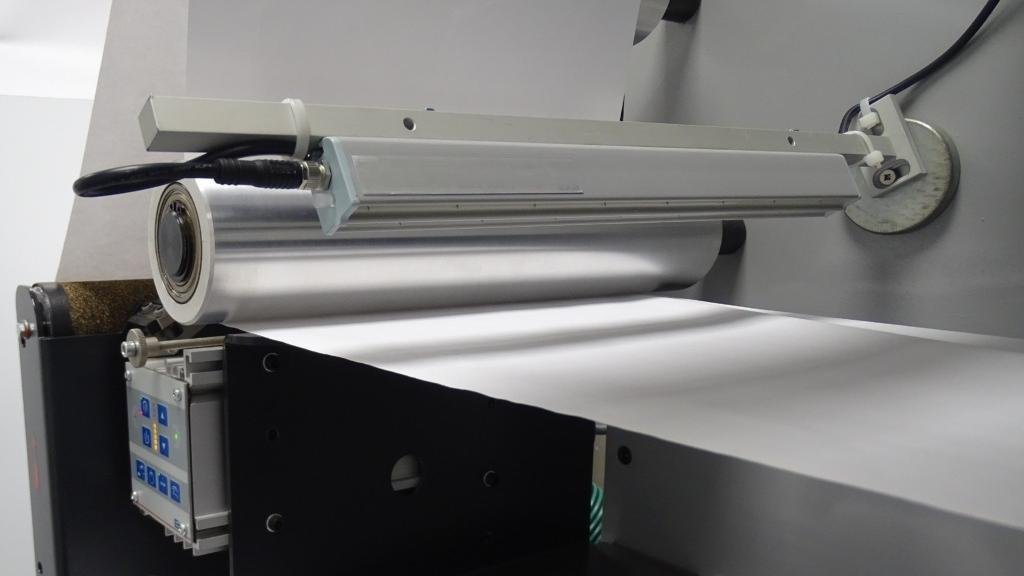

What Process Controls Are Crucial for Consistent Fiber Cutting?

You might have the perfect tool, but your results are still inconsistent. This unpredictability can ruin production runs and create a lot of expensive waste. Let's fix that.

It’s about managing the environment. First, control the temperature at the cutting zone, preferably with ionized air to also neutralize static. Second, keep the area clean. Third, and most important, ensure precise tool installation. Even tiny misalignments can destroy a tool's performance.

A great tool is only part of the equation. Sustainable performance comes from building a reliable process around it. These are the final steps I walk my clients through to ensure they get the best possible results and tool life.

Keep It Cool and Static-Free

Managing heat is everything. In the client case I mentioned, adding an air cooling device was a key part of our solution. I often recommend ionized air because it does two jobs at once. It cools the cutting edge to prevent melting, and the ions neutralize any static electricity. This stops dust from clinging to everything and helps the fiber feed smoothly without tangling or misaligning.

Manage the Workspace

A clean and controlled environment is not a luxury; it's a necessity. Keep the cutting area free of dust and debris that can cause extra abrasion. Controlling the humidity in the room can also help reduce static buildup naturally. For high-speed lines, installing active static eliminators near the machine ensures the fiber moves exactly where it needs to, every single time.

Installation is Critical

This is the one thing people overlook the most. You can invest in the best blade in the world from a company like PASSION, but it will fail if it's not installed perfectly. Ensure the tool mounting is parallel, concentric, and has the exact clearance it needs. A tiny error can cause the blade to wear unevenly, chip, or produce a poor cut. This single step can undermine all your other hard work.

Conclusion

Success in fiber cutting requires a complete system. It's about combining the right tool design, smart process controls, and precise maintenance to achieve clean, efficient cuts every single time.

Choosing the right tool material can significantly enhance cutting performance and tool longevity. ↩

Coatings can improve tool performance and lifespan by reducing friction and preventing material buildup. ↩

Proper installation ensures optimal tool performance and longevity, preventing premature wear. ↩