A single faulty blade can halt your entire production line. This unexpected downtime costs money and creates delays. A proper inspection routine1 is your first line of defense against these issues.

To inspect an industrial blade, you must check its appearance for defects like cracks or rust, verify its dimensions and tolerances with precision tools, test its hardness, and confirm its sharpness to ensure it meets specifications and fits your equipment perfectly.

A small detail missed during inspection can lead to big problems for clients. It's not just about getting a new blade; it's about making sure that blade performs flawlessly from the very first cut. Ensuring every blade is perfect is a core part of what we do. This commitment protects our clients' machinery and keeps their operations running smoothly. So, let’s walk through the essential checks that I recommend to all my partners.

Why Is A Thorough Blade Inspection So Critical For Your Operations?

Ignoring blade inspections seems like a time-saver. But a damaged or incorrect blade can cause catastrophic machine failure. This leads to costly repairs and even puts your operators at risk.

A thorough blade inspection is critical because it directly impacts production quality, machine longevity, and operator safety. It prevents material waste, reduces equipment strain, and avoids accidents caused by blade failure, saving you significant time and money in the long run.

A detailed inspection is the final quality gate that ensures the precision we manufacture is delivered to your factory floor. I once cooperated with a client from Italy, who runs a large plastics facility. He learned this lesson the hard way. A hairline crack in a new slitting blade, missed during a hasty installation, caused the blade to shatter mid-operation. It damaged the machine and forced a three-day shutdown. After that incident, he implemented the very inspection process I'm about to share with you. He told me it completely changed his maintenance routine and has prevented any similar issues since.

What Are The Non-Negotiable Checks For Every Industrial Blade?

You have a new blade, and you're ready to install it. But you worry if it's truly perfect for the job. Skipping a detailed check can lead to poor cuts or machine damage.

The non-negotiable checks for any industrial blade are a detailed visual inspection2, precise dimensional measurement3, hardness verification4, and a sharpness assessment5. These pillars ensure the blade is free from defects, meets exact specifications, and is ready for optimal performance.

Based on my experience helping countless customers, I have broken down the inspection process into a clear, structured system. It’s what we use internally at PASSION and what I recommend to all our clients. Focusing on these key areas ensures nothing is overlooked.

Visual Appearance Check

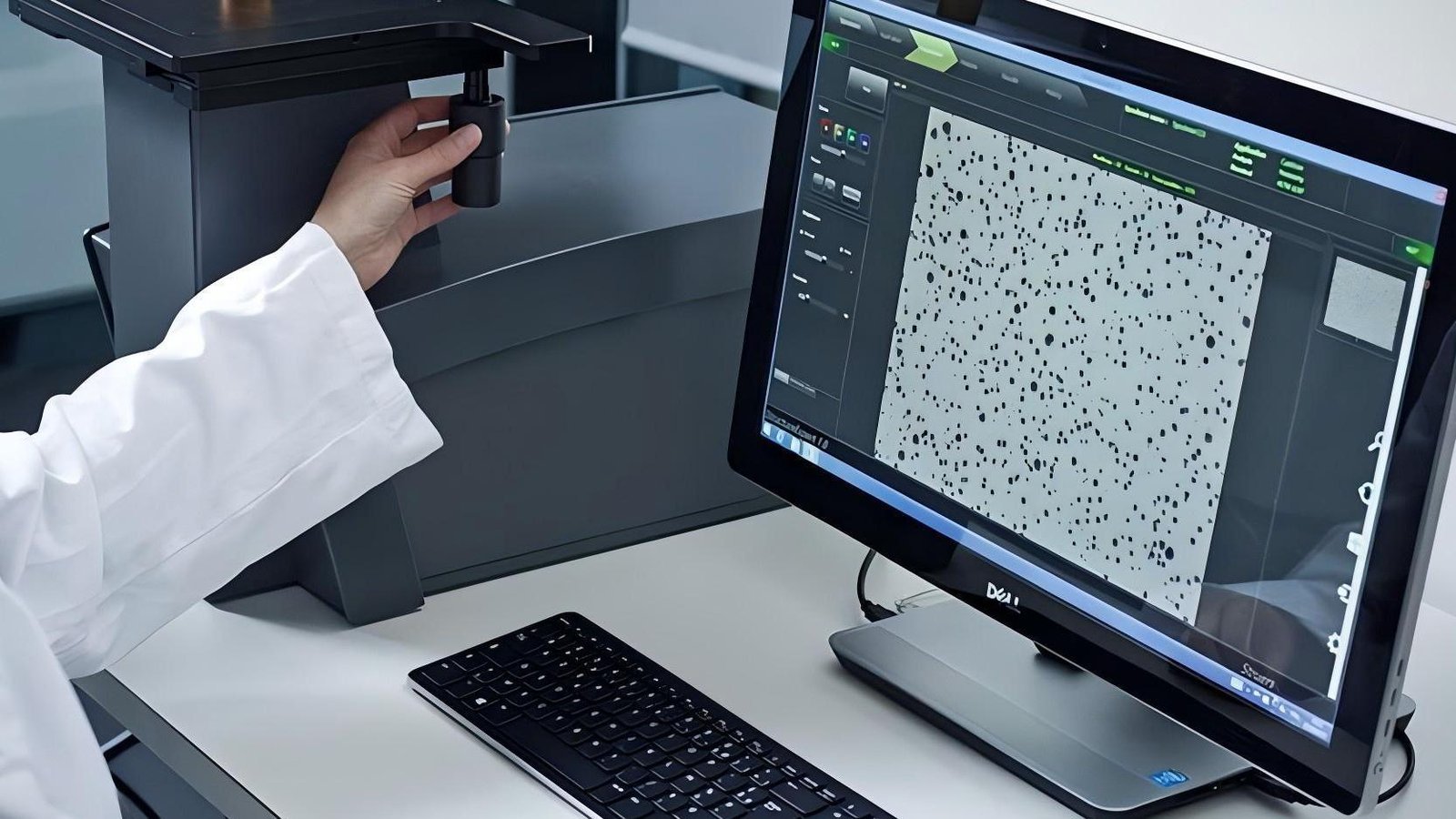

This is your first and simplest step. Look for any visible flaws on the blade's surface. Even a small defect can become a major failure point under the stress of high-speed cutting. Pay close attention to the cutting edge and the mounting holes, as these are critical areas.

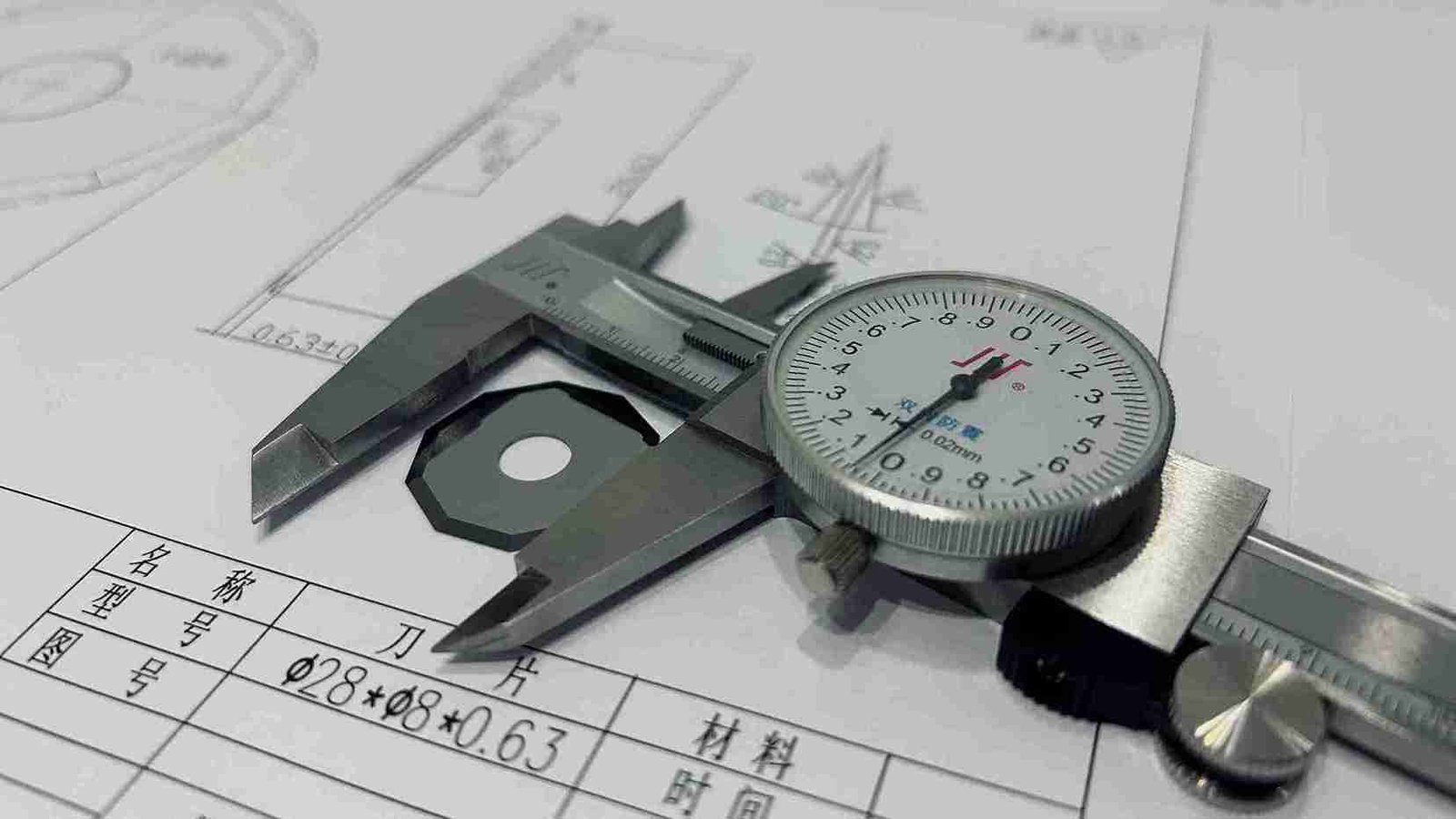

Dimensional Accuracy

Here, precision is everything. A blade that doesn't fit correctly is not just ineffective; it's dangerous. It can cause vibrations that damage your machinery and create an unsafe working environment.

| Parameter | Measurement Tool | Why It's Important |

|---|---|---|

| Outer Diameter/Length | Caliper, Micrometer | Ensures it fits within the machine's allocated space. |

| Inner Hole Diameter | Bore Gauge, Plug Gauge | Guarantees a snug and secure fit on the machine's shaft. |

| Thickness | Micrometer | Affects cutting clearance and stability. |

| Cutting Edge Angle | Protractor, Angle Gauge | Determines cutting performance and blade lifespan. |

Material and Hardness Verification

The blade's material and its hardness determine its durability and performance. It must be hard enough to hold an edge but not so brittle that it shatters. Using a hardness tester can confirm the blade meets the HRC rating required for your specific application.

How Did A Detailed Inspection Save A Client's Production Line?

A client expects a new set of blades to boost efficiency. But without a proper check, they install a slightly mismatched blade. This leads to uneven wear, bad cuts, and production halts.

Implementing a strict, detailed inspection process saved a client's production line by identifying a blade with a minute dimensional error before installation. This simple check prevented a costly machine breakdown, eliminated material waste, and maintained their tight production schedule without interruption.

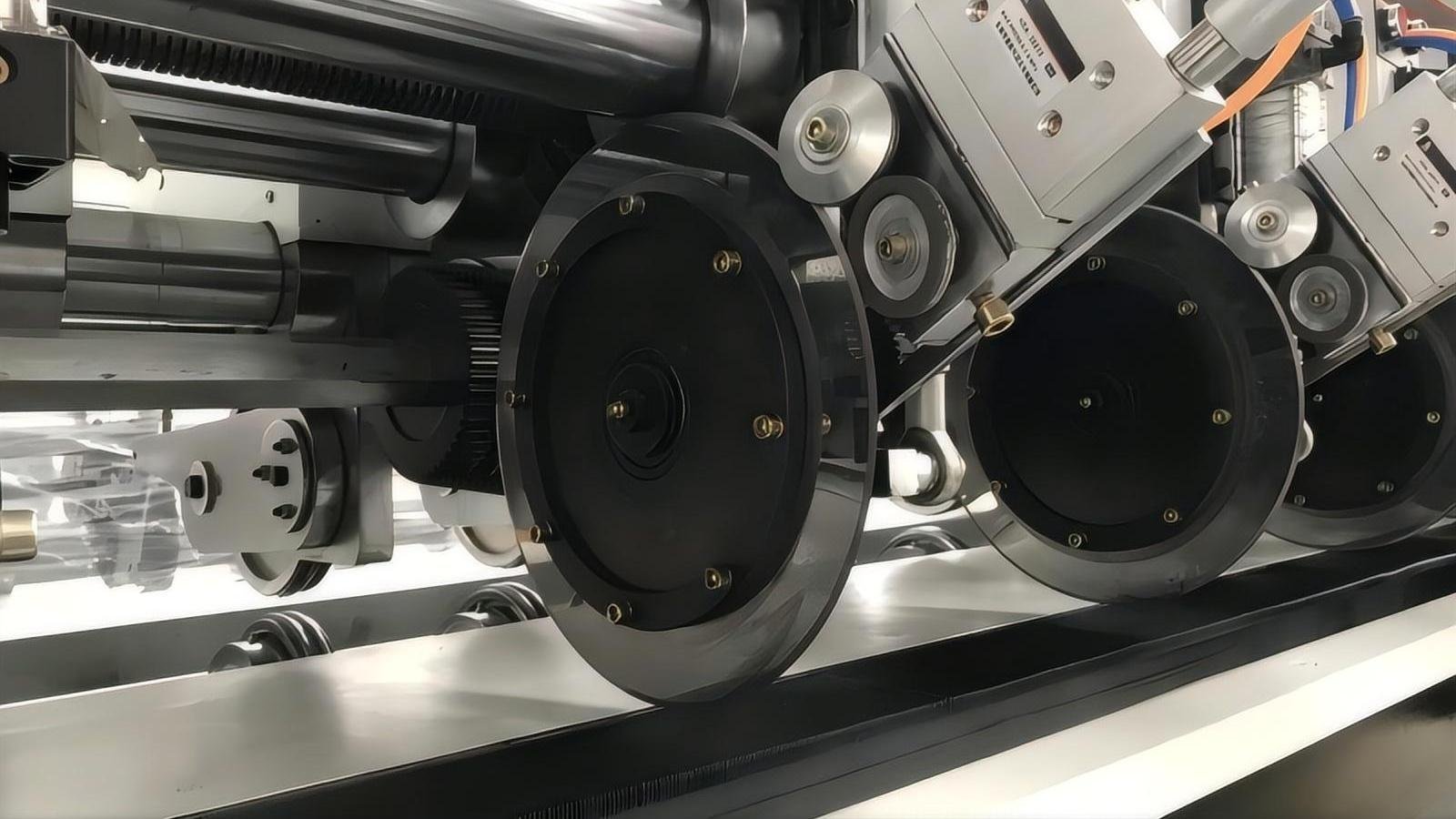

I remember my Mexican client Macaria, who runs a packaging company. They were cutting corrugated cardboard, a surprisingly abrasive material. Their slitter machine was using a set of 20 circular blades, and they were experiencing frequent "dusting" and frayed edges, which was causing their products to fail quality control. They blamed blade quality, but I suspected something else.

The Problem On-Site

Later, it was discovered that their team installed new blades without taking any measurements throughout the entire process. They believed that as long as the blades could be fitted onto the shaft, it meant the installation was successful. The problem was that the cumulative tolerance stack-up6 across 20 blades was creating gaps and overlaps, leading to poor cuts.

My Recommended Solution

I walked their maintenance manager through a simple inspection routine for each new blade before installation. Using a digital micrometer to check the thickness and a bore gauge for the inner hole of every single blade.

| Inspection Step | Action Taken | Result |

|---|---|---|

| 1. Unboxing | Laid out all new blades on a clean surface. | Immediately identified one blade with a visible surface scratch. |

| 2. Thickness Check | Measured each blade's thickness at three points. | Found two blades that were 0.02mm outside the required tolerance. |

| 3. Inner Hole Check | Used a bore gauge to confirm the inner diameter. | All PASSION blades were perfect, but found issues in their old stock. |

| 4. Matched Set | Assembled a perfectly matched set of 20 blades. | The machine ran smoothly, and the cut quality was flawless. |

By implementing this pre-installation check, the client eliminated their quality issues almost overnight. They realized that the small amount of time spent on inspection saved them hours of downtime and thousands of dollars in wasted material. It was a powerful lesson in how "Precision in Every Cut" really begins with precision in every check.

Conclusion

In summary, a systematic inspection of appearance, dimensions, and hardness is essential. This simple process ensures blade performance, protects your machinery, and guarantees the safety of your operators.

Exploring effective inspection routines can enhance your production efficiency and reduce unexpected failures. ↩

Visual inspections are crucial for identifying defects early, ensuring safety and performance in operations. ↩

Dimensional measurement ensures blades fit perfectly, preventing dangerous vibrations and machine damage. ↩

Learning about hardness verification can help you select blades that maintain their edge and performance. ↩

Understanding sharpness assessment methods can ensure optimal cutting performance and reduce material waste. ↩

Understanding tolerance stack-up can help you avoid issues that lead to poor cuts and machine failures. ↩