Struggling with CNC blade selection? The wrong choice can ruin jobs and raise costs. I'll show you how to pick the perfect blade by focusing on what truly matters.

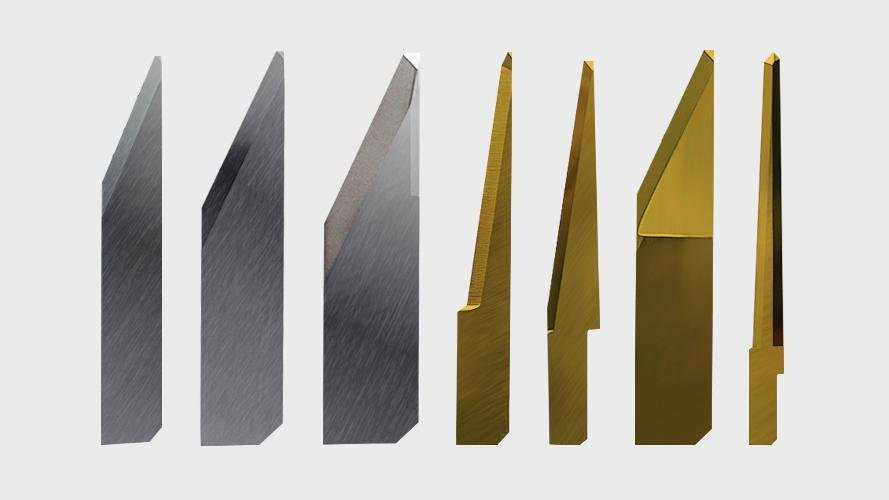

Choosing the right CNC blade goes beyond standard dimensions. You must match the blade material1 (like carbide2 or PCD3) and coating4 (like TiN5 or DLC6) to your specific workpiece material and cutting conditions. This ensures optimal performance, extends tool life, and reduces long-term production costs.

So, we know the basics are about more than just size. But how do these factors play out in the real world? It's one thing to know the theory, but seeing it in action makes all the difference. Let's break down the most critical elements you need to consider, one by one.

How Does Blade Material Impact Your CNC Cutting Performance?

Is your blade wearing out too fast? Using the wrong material leads to breakage and rough finishes. I'll help you match the blade material to your job for better results.

The blade material is critical. Use standard carbide inserts for most metalworking. For finishing high-hardness materials, choose ceramic or CBN. If you're cutting non-ferrous metals like aluminum, PCD inserts will deliver the best performance and longevity. Matching the material to the workpiece is key.

Let's look closer at this. The material isn't just a label; it defines the blade's core properties—how it handles heat, shock, and abrasion. Your choice here has a direct impact on your machine's efficiency and your final product's quality. I remember a client in Brazil working in the food processing equipment industry. They were machining stainless steel parts and their carbide blades were wearing down incredibly fast, causing constant production stops.

Material Selection Breakdown

We analyzed their process. They needed both toughness and heat resistance. We suggested switching to a specific grade of carbide with a higher cobalt content for increased toughness. This simple change dramatically reduced their tool changes and improved their uptime. This shows that a small adjustment in material can solve a big production problem. It all starts with understanding what you are cutting.

Here's a simple guide:

| Material | Best For | Key Property |

|---|---|---|

| Carbide | General Metalworking (Steel, Iron) | Versatility & Toughness |

| Ceramic/CBN | Hardened Steel, Cast Iron (Finishing) | Extreme Hardness & Heat Resistance |

| PCD | Aluminum, Copper, Composites | High Wear Resistance & Speed |

Why Is The Right Coating On Your Blade So Important?

Do your blades seem to dull quickly? The wrong coating, or no coating at all, leads to rapid wear and overheating. A proper coating acts like armor for your blade.

Coatings are essential for performance. They provide wear resistance, reduce friction, and dissipate heat from the cutting edge. Common types like TiN (Titanium Nitride) and TiAlN (Titanium Aluminum Nitride) allow for higher speeds and extend the tool's life significantly, especially in demanding applications.

Think of a coating as a specialized shield. It's a micro-thin layer, but it completely changes how the blade interacts with the workpiece. It can make a good blade great. A customer I worked with in Germany was in the business of manufacturing molds from hardened steel. Their uncoated carbide tools were struggling with the high temperatures generated during high-speed machining. This led to a poor surface finish on their products.

Coating Function And Selection

I recommended they try a blade with an AlCrN (Aluminum Chromium Nitride) coating. This coating is known for its excellent high-temperature oxidation resistance. The result was immediate. They could increase their cutting speeds, and the tool life more than doubled. The finish on their molds was perfect. Choosing the right shield for your blade is just as important as the blade itself. It prepares the tool for the specific battle it's about to face.

Here’s a quick overview of common coatings:

| Coating | Primary Benefit | Ideal Use Case |

|---|---|---|

| TiN | General Purpose, Wear Resistance | Lower-speed cutting, drills |

| TiAlN | High-Temp Resistance | High-speed dry machining |

| AlCrN | Superior Oxidation Resistance | Machining hardened steels, molds |

| DLC | Low Friction | Non-ferrous materials (Aluminum) |

How Do Your Machine Settings Affect Blade Choice?

Are your cuts inconsistent even with a good blade? Your machine settings might be the problem. A mismatch can lead to chatter, breakage, and poor-quality parts. Let's fix that.

You must match the blade to your machine's capabilities. A high-power, rigid machine can use tougher blade grades for aggressive cuts. Less stable machines need sharper geometries to reduce cutting forces. Your cooling method—flood coolant, MQL, or dry—also directly influences the ideal blade and coating choice.

It's a common mistake to think a high-performance blade will work perfectly on any machine. The entire system has to work together. Your machine's power, rigidity, and cooling system are part of the equation. I once assisted a client in Turkey who ran a small shop making parts for the textile machinery industry. They bought an advanced, coated blade but saw terrible results. They experienced chatter and chipping on the blade.

Aligning Blade With Machine

Their problem wasn't the blade; it was their machine. It was an older, less rigid model. The high-performance blade was designed for aggressive cutting forces that their machine couldn't handle. We switched them to a blade with a sharper cutting edge and a specific geometry designed to reduce tool pressure. Instantly, the chatter disappeared and their part quality improved. The best blade in the world will fail if it's not the right blade for your specific machine and setup.

Let's break down the key machine factors:

| Machine Factor | Implication for Blade Choice |

|---|---|

| High Power/Rigidity | Use tougher blade grades for higher material removal rates. |

| Low Power/Rigidity | Use sharp, positive rake blades to reduce cutting forces. |

| Flood Coolant | Allows for higher speeds; coating choice less critical for heat. |

| Dry/MQL | Requires coatings with high heat resistance (e.g., TiAlN). |

Conclusion

Choosing the right CNC blade is simple. Look past standard sizes and focus on matching the material, coating, and operating conditions to your job. This guarantees efficiency and quality.

Understanding blade material is crucial for optimizing cutting performance; find detailed resources on this topic. ↩

Discover the benefits of carbide blades and how they can improve your machining processes. ↩

Learn about PCD blades and their applications for non-ferrous metals to enhance your machining efficiency. ↩

Explore the significance of blade coatings and how they can extend tool life and improve performance. ↩

Find out how TiN coating can enhance the performance of your CNC blades in various applications. ↩

Learn about DLC coating and how it can reduce friction and improve the performance of your tools. ↩