Your slitting knives get dull way too fast. Production stops, cut quality drops, and blade costs add up. The problem is hidden inside the cardboard itself.

The main culprits are abrasive mineral impurities in recycled paper, chemical adhesives that cause corrosion, humidity changes, and uneven hardness between layers. These factors cause extreme abrasive wear, chipping, and dulling, which can cut blade life by 50%.

As a Sales Manager at PASSION, I often hear from clients in the packaging industry who are frustrated with their blade lifespan. They think they have a bad batch of knives, but the issue is often the very material they are cutting. Corrugated board is not just simple paper; it's a complex and surprisingly aggressive material to cut. Let's break down exactly what's in this board that is killing your blades. Once you understand the enemy, we can find the right solution.

Why Do Recycled Fibers Act Like Sandpaper On Your Knives?

Your knives develop grooves and fail prematurely. You're losing up to half of your expected blade life. The recycled paper content in your board is to blame.

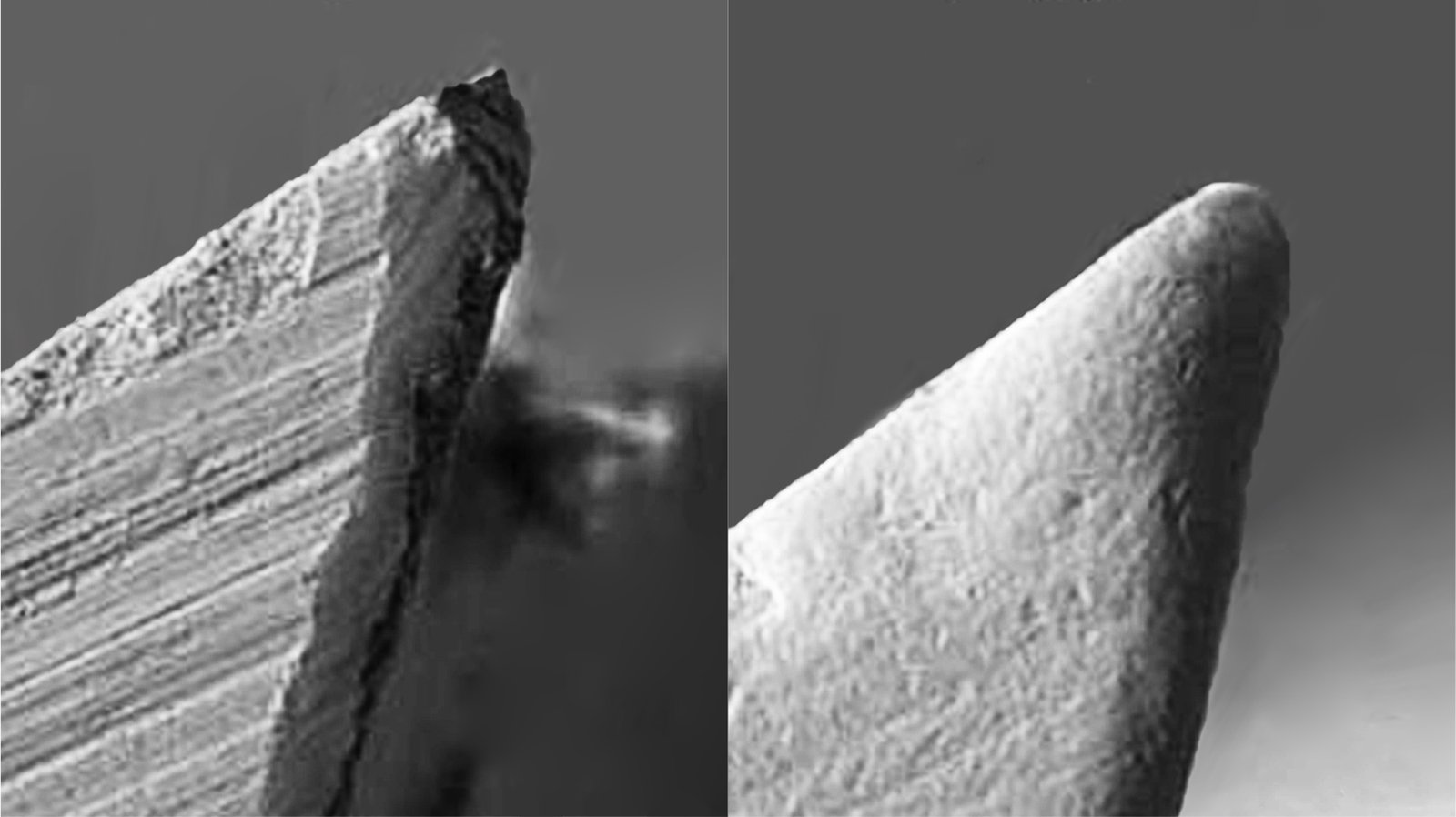

Recycled paper is full of hard mineral impurities like sand, clay, and talcum powder. These tiny particles act like sandpaper, grinding away at the blade's edge. This abrasive erosion causes deep wear grooves and ruins cut quality.

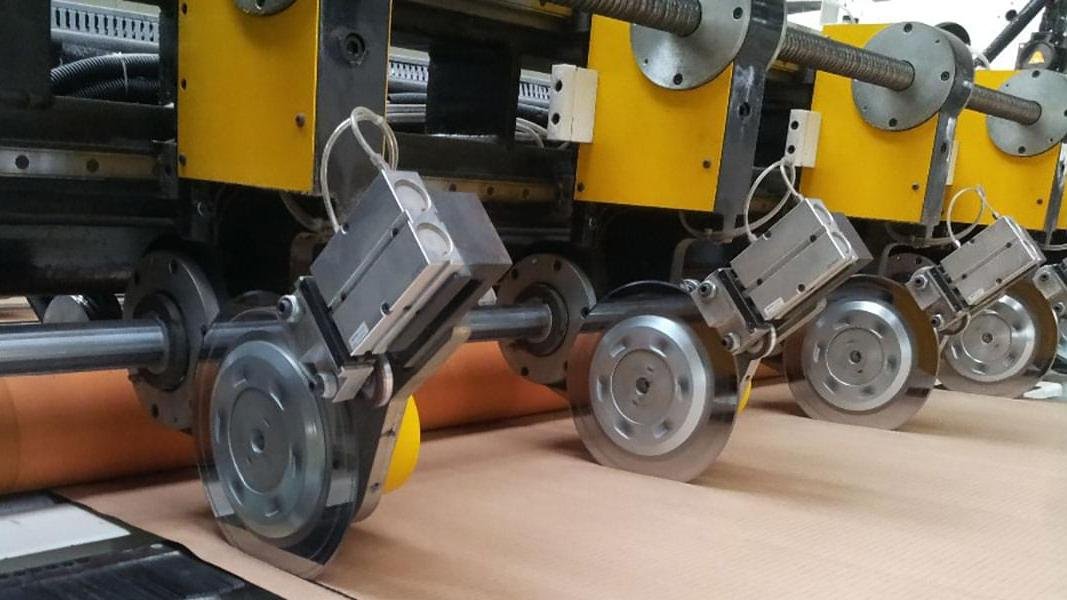

I once worked with a large box manufacturer who saw their blade life drop by 40%. When they sent us the worn knives, we saw clear evidence of abrasive wear under the microscope. The cutting edges were not just dull; they were grooved. We discovered they had recently switched to a new supplier for their linerboard who used a higher percentage of recycled content. This "new" paper was full of tiny mineral contaminants. Their blades were essentially trying to cut through sandpaper all day long. This is a very common problem because most corrugated board is made from recycled fibers to save costs and be more environmentally friendly.

Fighting Abrasive Wear

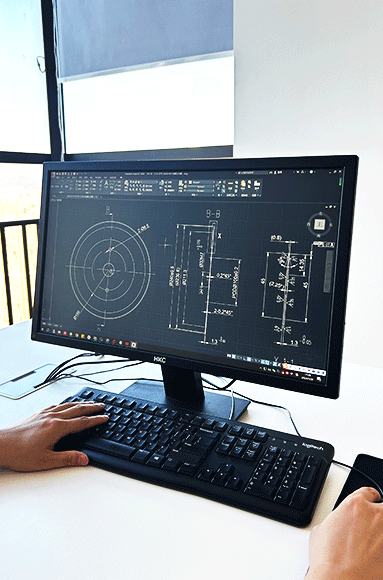

The key to solving this is a two-part approach: controlling what you can in the process and choosing a blade built to resist this specific type of wear.

- Process Control: While you can't always control your paper source, you can improve internal processes. Better filtration and cleaning systems for the paper can help remove some of these abrasive particles before they ever reach the slitting knife.

- Blade Technology: The most direct solution is to use a blade that is tougher than the abrasives. Standard steel blades will not last. At PASSION, we recommend tungsten carbide blades1 with specialized coatings for these conditions.

| Coating Type | Key Benefit | Best For |

|---|---|---|

| TiB₂ | Excellent hardness and low friction | High-volume cutting of highly abrasive board |

| CrN | High corrosion resistance and good toughness | Abrasive conditions with chemical exposure |

| DLC | Diamond-Like Carbon, extremely hard and slick | The most extreme abrasive environments |

For that client, we supplied a set of blades with a DLC coating2. The result was immediate. Their blade life went back to normal, and the cut quality improved because the sharp edge was maintained.

How Do Adhesives and Dust Create a Blade-Killing Combination?

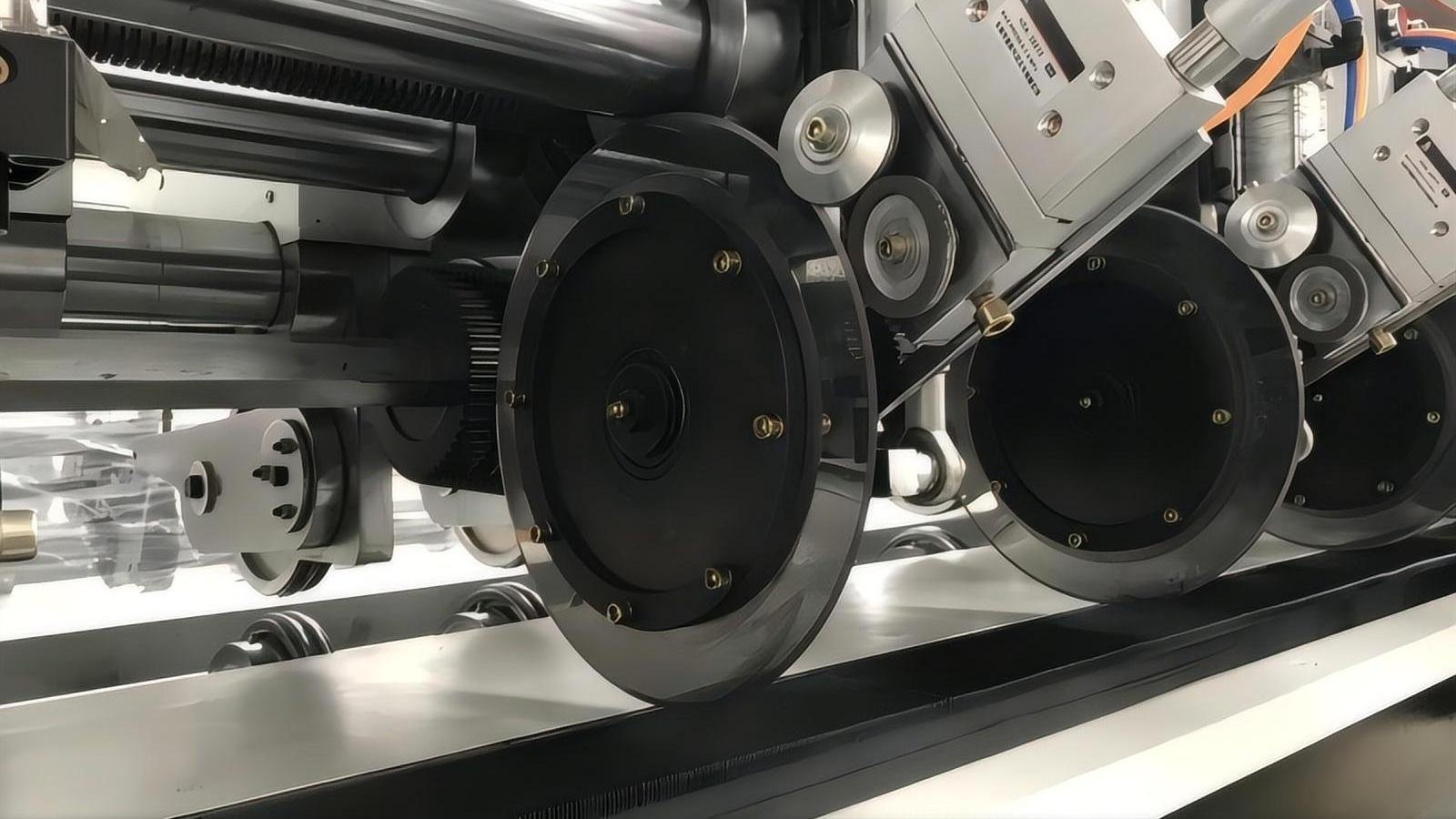

You notice a sticky, hard gunk building up on your blades. This buildup causes friction, bad cuts, and forces you to stop the line for cleaning.

The combination of paper dust and starch-based adhesive, heated by the friction of cutting, forms a hard bonding layer on the blade. This buildup increases friction, causes overheating, and can lead to chemical corrosion, drastically accelerating wear.

Buildup seems like a simple cleaning issue, but it's more serious than that. I had a customer who was struggling with this exact problem. Their machine operators had to stop and scrape the blades every few hours. The problem is that this buildup is not just dust. It's a mix of paper fibers, dust, and the starch paste used to glue the corrugated board layers together. The friction from cutting generates heat, which basically bakes this paste into a hard, cement-like deposit on the blade. This deposit does two bad things. First, it increases drag and friction, which generates even more heat and makes the blade dull faster. Second, some adhesives can be slightly acidic or alkaline, which causes slow chemical corrosion and weakens the steel of the blade edge.

Strategies to Prevent Buildup

A blade that stays clean will always cut better and last longer. You can fight buildup with the right blade choice and maintenance.

- Blade Finish: A blade with a highly polished, mirror-like surface finish will have less for the adhesive to stick to. We often recommend a fine-grind finish for customers dealing with sticky materials.

- Non-Stick Coatings: Certain coatings, like those with a low coefficient of friction, can significantly reduce how much material adheres to the blade. This means less cleaning and more consistent cutting performance.

- Regular Cleaning: Even with the best blade, a scheduled cleaning routine is essential. Using the right cleaning agents that can dissolve the starch paste without harming the blade material is key.

For my customer, the solution was a PASSION blade with a mirror-finish and a scheduled cleaning protocol3. The buildup was reduced by over 80%, which meant they could run the line for a full shift without stopping.

Why Do Inconsistent Board Conditions Cause Blades to Chip and Crack?

Your blades are suddenly chipping or cracking, but the wear doesn't look that bad. These sudden failures are unpredictable and cause major downtime on your production line.

Corrugated board has multiple layers with different hardness levels. Also, changes in humidity and temperature alter the board's properties. This creates fluctuating stress and thermal shock on the blade edge, leading to micro-chipping and fatigue cracks.

Many people think of cardboard as a uniform material, but it's not. A blade cutting through corrugated board is facing a constantly changing environment. It slices through the top liner, then the wavy medium, then the bottom liner. Each layer has a different density and hardness. I explain this to my clients like this: imagine you are chopping wood, and you suddenly hit a hidden knot. The shock can damage your axe. The blade experiences this same shock thousands of times a minute. This alternating stress creates microscopic cracks that can grow into a larger chip. On top of this, environmental changes matter. When humidity drops, the board gets drier and harder. When it rises, it gets softer. This constant change in friction causes thermal stress, which further weakens the blade and makes it brittle over time.

Building a Resilient Cutting Edge

To survive these conditions, a blade needs to be tough and resilient, not just hard.

| Challenge | Root Cause | Recommended Blade Characteristic |

|---|---|---|

| Micro-Chipping | Alternating stress from different layers | High toughness (impact resistance) |

| Thermal Fatigue/Cracking | Fluctuating friction from humidity changes | Good thermal shock resistance |

| Accelerated Wear | Hard pigments (e.g., TiO₂) in coated papers | High abrasive wear resistance (e.g., carbide) |

At PASSION, we don't believe in a one-size-fits-all blade. For customers cutting a wide variety of board, especially coated or printed stock with hard pigments, we recommend specific tungsten carbide grades. These grades are engineered to have the right balance of hardness for wear resistance and toughness to absorb the shock of cutting through inconsistent layers without chipping.

Conclusion

The board you cut directly impacts blade life. Understanding its abrasive, chemical, and physical challenges is key. At PASSION, we engineer blades to overcome these specific problems for longer life.