Struggling to choose between a conventional industrial machine blade1 and a hot knife2? The wrong decision wastes material and money. Let's find the right tool for your specific cutting needs.

The best choice depends on your material. Conventional industrial machine blades offer high precision for almost any material. Hot knives are perfect for thermoplastics3 like plastics and synthetic fabrics, creating a clean, sealed edge by melting the material as it cuts. This prevents fraying and ensures a smooth finish.

Choosing the right blade is a critical decision in any production line. A poor choice can lead to failed quality checks, damaged equipment, and production delays. To help you avoid these problems, let's explore the details of each cutting method. Understanding their core differences will empower you to make an informed decision that boosts your efficiency and product quality.

Why Is Conventional Mechanical Cutting The Industry Standard For Precision?

Mechanical cutting is the standard because it uses pure force for unmatched accuracy. It cuts without heat, preserving the material's original properties. This makes it ideal for metals, paper, and composites where dimensional stability is essential for high-quality finished products.

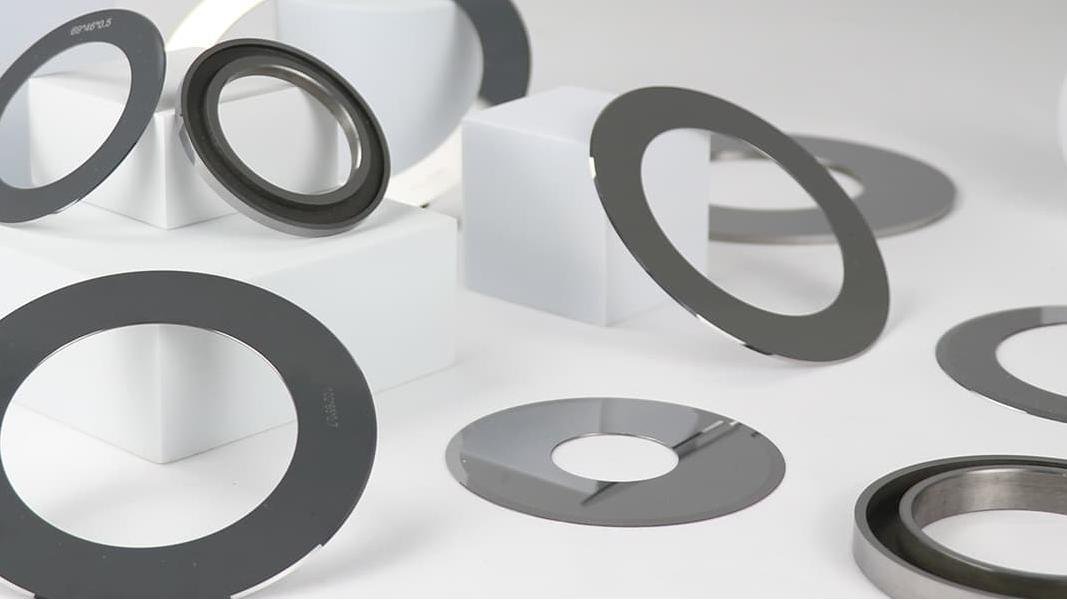

Traditional mechanical cutting is all about pure physical force. The process uses blades to shear, punch, or slice through materials. At PASSION, we manufacture these tools from incredibly hard materials like cemented carbide, SKD11, and high-speed steel (HSS)4. This ensures they have the strength and wear resistance for high-volume production. The main advantage is precision. Because this method does not use high temperatures, the material’s physical and chemical structure remains unchanged. This is crucial for industries where exact dimensions are non-negotiable.

I remember working with a client in the packaging industry in Germany. They were cutting thick, high-grade cardboard for luxury product boxes. Their previous system generated too much heat, which caused slight warping at the edges. This was unacceptable for their premium brand. We switched them to one of our high-chromium steel slitting blades. The result was immediate. The cuts were perfectly clean and precise, with no thermal damage. Their production speed increased, and their quality control rejections dropped to almost zero. This case always reminds me how critical it is to avoid heat when dimensional accuracy is the top priority.

Key Aspects of Mechanical Cutting

- Process: Separation through shearing or compressive force.

- Materials: Suitable for almost all materials, including metals, paper, wood, and composites.

- Main Benefit: High precision and no heat-affected zone.

- Drawback: Can sometimes produce burrs5 or minor tearing on very flexible or soft materials.

When Is A Hot Knife The Superior Cutting Solution?

Are frayed edges and material tearing ruining your flexible materials? This common issue can halt production lines. A hot knife2 offers a perfect, sealed finish every time.

A hot knife2 is superior when cutting thermoplastics3 like synthetic fabrics, ropes, and foam. Its heated blade melts the material, creating a smooth, sealed edge. This process entirely prevents fraying or unraveling, which is a major advantage over mechanical cutting for these specific materials.

Hot knife cutting works on a completely different principle. It uses an electric heating element, often made of a nickel-chromium alloy, to raise the blade's temperature to several hundred degrees. When the hot blade touches the material, it causes localized melting, which separates it. The most significant benefit is the edge finish. As the hot knife2 cuts, it also seals the edge. This is perfect for thermoplastic and flexible materials like plastic films, foams, and synthetic fabrics. The sealed edge prevents delamination, fraying, or chipping, which is vital for the appearance and durability of the final product.

A few years ago, a client from Brazil who manufactures large banners from synthetic woven fabrics contacted me. They were using mechanical cutters, but the edges were constantly fraying. This meant they had to add an extra step to sew or seal the edges, which was slow and costly. We recommended they integrate a hot knife2 cutting system. The heated blade sliced through the fabric and sealed the edges in a single pass. The difference was incredible. They eliminated an entire production step, saved on labor, and produced a much cleaner, more durable final product. It's a great example of how heat, when used correctly, can be a powerful ally.

Key Aspects Of Hot Knife Cutting

- Process: Separation through localized melting.

- Materials: Primarily used for thermoplastics like plastic films, foams, and synthetic textiles.

- Main Benefit: Produces a smooth, burr-free, and sealed edge.

- Drawback: Lower precision and can cause thermal deformation, making it unsuitable for high-tolerance parts.

How Do You Choose The Right Tool For Your Material?

Choosing between mechanical force and thermal energy can be confusing. Making the wrong call leads to production issues. Let's compare them directly to simplify your decision-making process.

To choose, consider your material and desired edge finish. For precision on rigid materials like metal or paper, use a machine blade1. For a sealed, fray-free edge on thermoplastics3 like plastic film or synthetic fabric, use a hot knife. Your priority dictates the right blade.

The simplest way to think about this is to decide if heat is your "ally" or your "enemy." In mechanical cutting, heat is a byproduct generated from friction—an enemy you want to minimize to maintain material integrity and precision. In hot knife2 cutting, heat is the primary tool—an ally that allows for a clean, sealed cut. This fundamental difference dictates which materials and applications each method is suited for.

I once advised a company in the automotive sector. They were producing interior panels made of a composite material—a thermoplastic fabric layer bonded to a rigid backing. They needed the precision of a mechanical cut for the overall shape but struggled with frayed edges on the fabric layer. The solution was a hybrid approach. We helped them set up a process using a mechanical punch for the main shape and a secondary pass with a custom-shaped hot knife just to seal the fabric edge. It shows that sometimes, the best solution isn't just one or the other, but understanding how to use both technologies to your advantage.

Direct Performance Comparison

| Feature | Mechanical Cutting | Hot Knife Cutting |

|---|---|---|

| Core Principle | Mechanical Force (Shear, Compression) | Thermal Energy (Melting) |

| Role of Heat | Unwanted byproduct ("Enemy") | Primary tool ("Ally") |

| Applicable Materials | Nearly all materials (metals, wood, paper, plastics) | Primarily thermoplastics (plastics, foams, synthetics) |

| Cut Surface | Precise, but may have burrs | Smooth, sealed, and fray-free |

| Chips/Dust | Generates chips or dust | Virtually no chips or dust |

| Precision | Very High | Lower, with risk of thermal deformation |

| Energy Consumption | Generally Lower | High due to continuous heating |

Conclusion

The best cutting method depends entirely on your material and production goals. Mechanical blades offer precision and versatility, while hot knives provide perfectly sealed edges for thermoplastics.

Explore the versatility and applications of machine blades in various industries. ↩

Learn how hot knives can improve cutting efficiency and edge quality for thermoplastics. ↩

Understand the properties of thermoplastics and why they require specific cutting methods. ↩

Learn about the properties and applications of high-speed steel in cutting tools. ↩

Learn about burrs in cutting processes and effective methods to eliminate them. ↩