Struggling to find cost-effective industrial blades? You worry that a lower price means poor performance. Carbon steel offers a solution balancing cost and quality for the right applications.

The affordability of carbon steel blades1 comes from two main factors: low raw material costs and a simple, efficient manufacturing process2. Iron and carbon are abundant and inexpensive, and the steel is easy to machine, heat-treat3, and sharpen, reducing production time and overall expense.

Understanding why these blades are so economical is key to deciding if they are right for your operation. It is not just about the price tag. It is about getting the right tool for the job without overspending. Let's break down the factors that make carbon steel a popular choice and explore where its cost-saving benefits truly shine, and where you might need to consider an alternative.

Why Are Low Raw Material Costs The Root Of Carbon Steel's 'Economical' Nature?

High material costs can significantly impact your bottom line. Choosing the wrong blade material based on price alone can be a costly mistake. Let's look at the source.

Carbon steel's low raw material cost is due to its simple composition of iron and carbon. These elements are two of the most abundant and cheapest on Earth. Unlike alloy steels, it does not require expensive additives like tungsten, cobalt, or chromium to achieve its properties.

Carbon steel is fundamentally an alloy of iron and carbon. There are no expensive, rare-earth metals involved. Compare this to high-speed steel (HSS), which needs costly elements like tungsten and molybdenum for heat resistance, or tungsten carbide, which relies on cobalt as a binder. The global steelmaking process for basic carbon steel is also incredibly mature and efficient. This massive scale of production drives the price down even further. For a client in the textile industry in Turkey, this difference was huge. They were using pricier alloy blades for cutting large fabric bolts. I suggested they try our carbon steel blades. Because the raw material cost was so much lower, we could provide them with a blade that reduced their consumable tooling budget by 30% without sacrificing the clean cut they needed.

Raw Material Cost Comparison

| Blade Material | Key Alloying Elements | Relative Raw Material Cost |

|---|---|---|

| Carbon Steel | Iron, Carbon | Low |

| Tool Steel (D2) | Iron, Carbon, Chromium, Molybdenum | Medium |

| High-Speed Steel (HSS) | Iron, Carbon, Tungsten, Vanadium | High |

| Tungsten Carbide | Tungsten, Carbon, Cobalt (binder) | Very High |

How Does Excellent Machinability Lead To Low Manufacturing Costs?

Complex manufacturing processes always drive up blade prices. Extended production times and the need for specialized equipment can make some blades very expensive. Carbon steel simplifies this entire process.

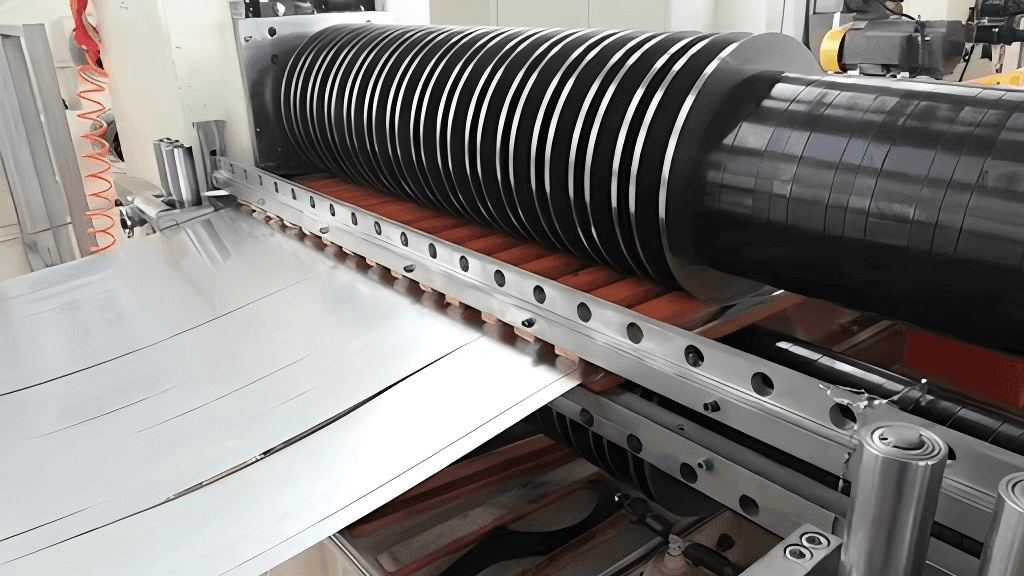

Carbon steel is relatively soft and easy to work with before it is heat-treated. This "machinability" means it can be shaped, ground, and sharpened faster, using less energy and causing less wear on factory tools, which significantly lowers overall production costs.

Machinability is a huge factor in manufacturing costs. In our factory, we can process carbon steel much faster than harder alloys. This means our milling machines, grinders, and other tools experience less wear and tear, and we use less energy. The heat treatment process is also very straightforward—typically a simple quench and temper. This is much less complex and energy-intensive than the multi-stage heat treatments required for HSS or the specialized sintering furnaces needed for tungsten carbide. All these efficiencies add up. I remember working with a paper converting company in Brazil. They were struggling with the high cost of their slitter blades. I discovered their previous supplier used a complex alloy that was difficult to machine. I explained how our carbon steel blades, thanks to their machinability, could be produced more efficiently. We provided them with blades that met their slitting needs for non-abrasive paper stock at a price that was 25% lower.

Manufacturing Step Comparison

| Manufacturing Step | Carbon Steel | High-Alloy Steel (e.g., HSS) |

|---|---|---|

| Initial Shaping | Fast, low tool wear | Slower, high tool wear |

| Grinding | Quick material removal | Slow, requires special grinding wheels |

| Heat Treatment | Simple quench & temper | Complex, multi-stage, high energy |

| Final Sharpening | Easy, fast | More time-consuming |

What Are The Key Advantages Of Using Carbon Steel Blades?

You are likely looking for a blade that is more than just cheap. You need reliable performance without destroying your budget. Carbon steel can offer an excellent balance of benefits.

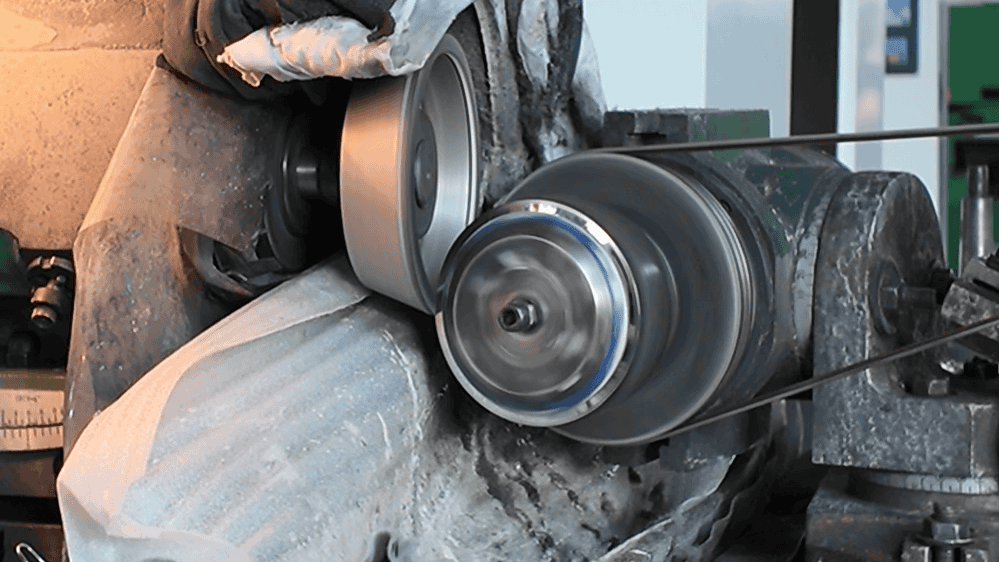

The key advantages of carbon steel blades are their ability to achieve exceptional sharpness4, their ease of re-sharpening5, and their very low initial cost. Their fine grain structure allows for a keen, precise edge, making them highly practical for many general-purpose cutting tasks.

While cost is the headline feature, the performance advantages for specific applications are just as important. The right blade makes all the difference, and sometimes, the simplest solution is the best.

Excellent Sharpness

Because of its simple grain structure, carbon steel can be honed to an incredibly fine, razor-sharp edge. This is a huge benefit in industries where a clean, precise cut is critical, such as in film, foil, and paper converting. A sharp blade reduces material deformation and dust, leading to a higher-quality final product.

Ease Of Maintenance

Carbon steel is not excessively hard, which is an advantage for maintenance. Users can often re-sharpen the blades themselves using standard equipment. This reduces downtime and removes the need to send blades out for specialized servicing. I worked with a food processing plant in Thailand that sliced vegetables. They needed an extremely sharp blade for a clean cut to prevent bruising. Carbon steel was the perfect fit. They got a very sharp blade at a low cost, and their own maintenance team could easily re-sharpen them daily.

Low Initial Investment

The combination of low material and manufacturing costs makes carbon steel blades the king of cost-effectiveness for many applications. They are an ideal choice for high-volume jobs where blades are considered a consumable item or for general-purpose tasks where a premium, long-life blade would be overkill.

What Are The Main Disadvantages To Watch Out For With Carbon Steel Blades?

Carbon steel might seem like the perfect, economical solution. But using it in the wrong application can cause equipment downtime and product quality issues. You need to understand its limitations.

The main disadvantages of carbon steel are its poor corrosion resistance6, low wear resistance7, and poor performance at high temperatures. It rusts easily, wears out quickly against abrasive materials8, and loses hardness when hot, which makes it unsuitable for many demanding industrial environments.

Choosing the wrong material can be far more expensive than buying the right one in the first place. This is where expertise is critical.

Poor Corrosion Resistance

Carbon steel's biggest weakness is rust. It contains no chromium or other elements to protect it from oxidation. In humid environments or when cutting materials with moisture or acidity, these blades will corrode quickly. This can contaminate the product being cut, a major issue in food processing or medical applications.

Lower Wear Resistance

When cutting abrasive materials like fiberglass, composites, or plastics with strengthening fillers, a carbon steel edge will wear down very fast. This leads to frequent blade changes, increased downtime, and poor cut quality. A client in the plastics recycling industry in Poland learned this the hard way. They tried using carbon steel blades in their granulators. The heat and abrasive nature of the material destroyed the blades within hours. We switched them to a D2 tool steel blade. The blade life9 increased by over ten times, saving them a huge amount of money in the long run.

Limited High-Temperature Performance

High-speed cutting operations generate a lot of heat at the blade's edge. Carbon steel loses its temper and hardness at relatively low temperatures. When the edge gets too hot, it becomes soft and fails almost instantly. This makes it unsuitable for high-speed metal cutting, slitting, or any application where friction-generated heat is a significant factor.

Conclusion

Carbon steel blades offer a great, affordable option for sharp, precise cutting in non-corrosive, low-abrasion environments. But for demanding applications, investing in a more durable alloy is often better.

Explore the advantages of carbon steel blades for cost-effective and reliable cutting solutions. ↩

Learn about the efficient manufacturing process that keeps carbon steel blades affordable. ↩

Understanding the heat-treat process is crucial for optimizing blade performance and longevity, ensuring you choose the right tools for your needs. ↩

Find out why sharpness is crucial for achieving clean and precise cuts. ↩

Learn about the maintenance advantages of carbon steel blades for users. ↩

Understand the importance of corrosion resistance in choosing the right blade material. ↩

Learn how wear resistance affects blade longevity and performance. ↩

Understand the limitations of carbon steel when dealing with abrasive materials. ↩

Explore strategies to enhance blade life and reduce operational costs. ↩