Are your packaged products difficult for customers to open? Do you struggle with inconsistent tear lines in your production? A simple change in your cutting tool could be the perfect solution.

Perforating knives1 are essential in the packaging industry because they create precise lines of cuts and holes. These perforations make packages easy for consumers to open and allow manufacturers to manage high-speed production efficiency and consistency.

I remember a client, Omar, a production supervisor in the UK. He was responsible for cutting and punching plastic bags. He used regular straight knives and often had problems with uneven holes and rough edges. His product quality dropped, and customer complaints went up. He came to us for advice. We recommended a specialized perforating blade. The new blade was sharp and precise. It increased his production speed and made the holes much neater. This simple change solved a long-standing quality problem for him. His story shows why understanding these blades is so important. Let's explore what makes them so effective.

How Do Perforating Blades Help Both The Factory And The Final Customer?

Juggling factory efficiency with customer satisfaction is tough. What if one tool could improve both at the same time? This is exactly what perforating blades are designed to do in packaging.

Perforating blades create a win-win situation. For manufacturers, they ensure consistent, high-speed production with accurate cuts. For consumers, they provide easy-to-open packaging with clean tear lines, which improves the overall product experience.

The benefits of perforating blades are clear for both sides of the supply chain. They add value in different ways for the factory and for the person buying the product. Let's break down how they help each group.

For The Manufacturer

For a company that makes packaged goods, efficiency and quality are everything. Perforating blades are critical for achieving both goals.

- Consistency: On a fast production line, every cut must be the same. These blades produce identical perforation patterns on thousands of packages per hour. This level of consistency is impossible to achieve by hand.

- Speed: The perforating blades are designed to work quickly. They fit into automated machinery and cut materials without slowing down the entire packaging process.

- Control: A key function is controlling the cut depth2. If the cut is too deep, the package might break during shipping. If it is too shallow, it will be hard to tear. High-quality blades give operators precise control over this balance.

For The Consumer

The final customer might not think about the blade, but they will notice its result.

- Easy Opening: This is the most obvious benefit. Think of a bag of chips or a box of cereal. The perforation line allows the customer to open the package without needing scissors.

- Neatness: A good perforation creates a clean tear. The package opens along the intended line without ripping or destroying the rest of the packaging.

What Are The Characteristics Of High-Quality Perforating Blades?

Your production line stopped because a blade broke. Now you have costly downtime and inconsistent products. A low-quality blade can create a lot of problems that are hard to fix.

A high-quality perforating blade must be sharp, durable, and precise. It should be made from tough materials, have a consistent tooth profile3 for clean cuts, and maintain its cutting edge for a long time.

When I work with clients, I always say that the blade's quality directly impacts the final product's quality. Choosing a cheaper, lower-quality blade often costs more in the long run. There are several key features to look for in a top-tier perforating blade.

First is the material. The blade needs to be made from high-grade steel that can handle wear. A stronger material means the blade stays sharp longer and does not chip or break easily. This is crucial for safety and continuous operation.

Next is precision manufacturing. The teeth on the blade must be perfectly uniform.

- Tooth Height: Every tooth should be the same height to ensure the cut depth is consistent.

- Tooth Spacing: The distance between each tooth must be exact. This ensures the package tears evenly.

- Sharpness: The cutting edge should be expertly ground. A sharp blade makes a clean cut with little force. A dull blade can crush the material. This was the problem Omar had before he switched to our blades.

Finally, consider the durability. A great blade is one you do not have to change often. It should hold its edge through thousands of cuts. This reduces machine downtime and saves the company money.

| Characteristic | Why It's Important | Impact of Poor Quality |

|---|---|---|

| Material Quality | Ensures blade longevity and strength. | Blade dulls quickly, breaks easily. |

| Precision Teeth | Creates a clean, consistent perforation. | Uneven tears, messy edges. |

| Edge Sharpness | Reduces cutting force, prevents material damage. | Crushed material, higher machine wear. |

| Durability | Minimizes downtime for blade changes. | Frequent stops in production. |

What Are The Common Materials For Perforating Blades?

You replaced a blade last week, but it is already dull. Choosing the right material is essential for performance. Using the wrong material leads to frequent replacements and poor cuts.

Common materials for perforating blades include Carbon Steel for basic tasks, Stainless Steel for food or medical use, and High-Speed Steel (HSS) or Tungsten Carbide for demanding, high-volume applications that require extreme durability.

The choice of material is one of the most important decisions. It affects the blade's lifespan, its performance, and the types of materials it can cut. I always ask my clients what they are cutting and at what speed before I recommend a material. Each type has its own strengths.

Carbon Steel

This is a common and affordable option. Carbon steel is hard and can be sharpened to a very fine edge. It works well for cutting paper and light plastics. However, it can rust, so it is not good for humid environments or food applications.

Stainless Steel

This is the choice for the food and medical industries. Its main advantage is its resistance to rust. This makes it easy to clean. It might not hold an edge as long as high-carbon steel, but its hygienic properties are necessary in certain applications.

High-Speed Steel (HSS)

When durability is key, HSS is a great choice. It can handle high temperatures and abrasion. This makes it perfect for high-speed production lines. It costs more than carbon steel, but its longer life often makes it more cost-effective.

Tungsten Carbide

For the toughest jobs, tungsten carbide is the top choice. It is an extremely hard material that holds a sharp edge much longer than any steel. It is ideal for cutting abrasive materials. The initial cost is high, but the blades last many times longer than HSS blades. This leads to big savings in downtime.

| Material | Best For | Pros | Cons |

|---|---|---|---|

| Carbon Steel | General purpose, paper | Affordable, sharpens easily | Prone to rust, wears faster |

| Stainless Steel | Food, medical use | Corrosion resistant, hygienic | Softer, needs more sharpening |

| High-Speed Steel | High-volume production | Durable, heat resistant | More expensive than basic steel |

| Tungsten Carbide | Very abrasive materials | Extremely long lifespan | High initial cost, can be brittle |

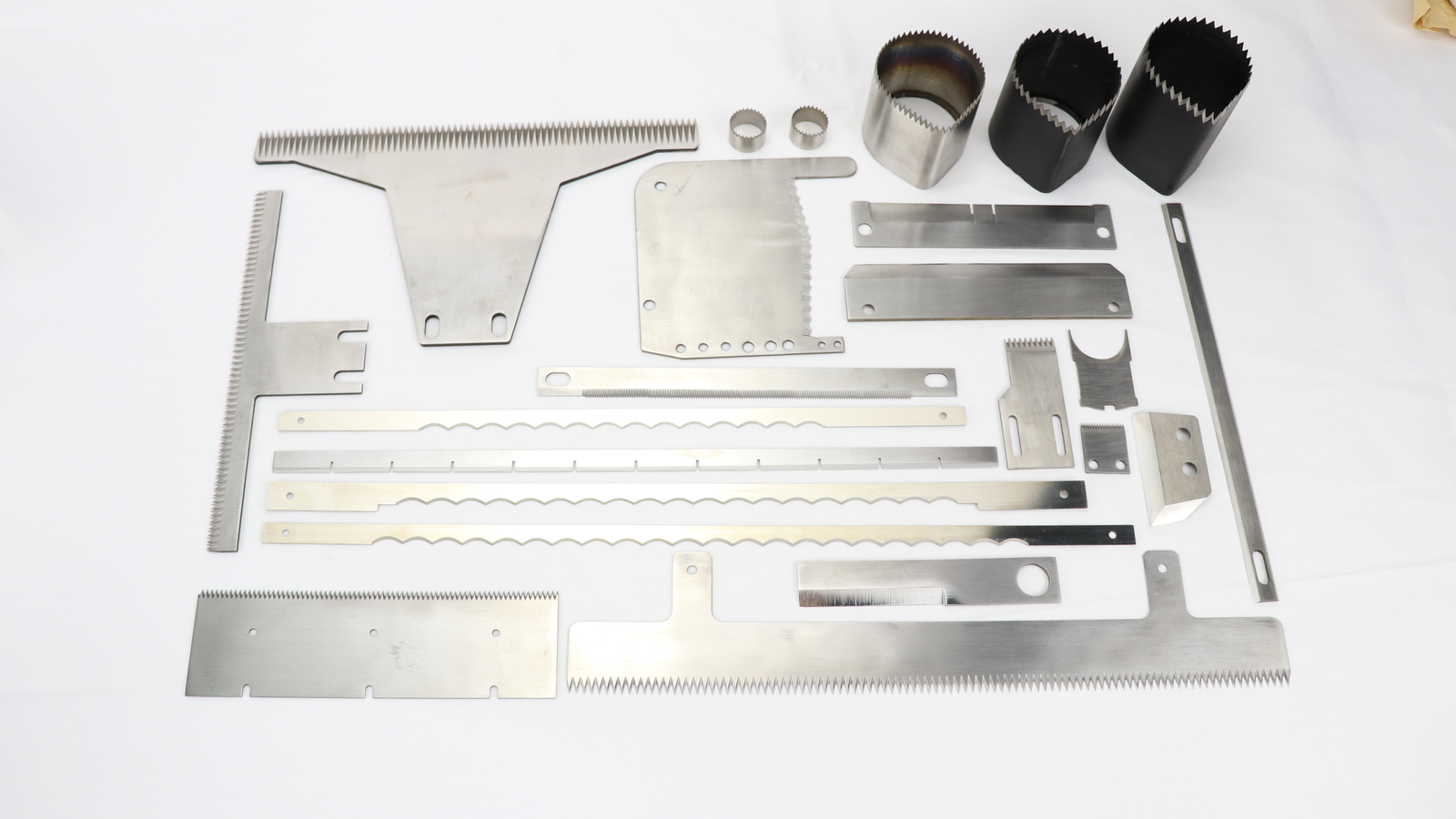

What Are The Common Tooth Profiles For Perforating Blades?

Does your perforation tear cleanly or does it rip unevenly? The shape of the teeth on your blade makes all the difference. Choosing the wrong tooth profile can ruin your packaging.

Common tooth profiles include standard profiles for all-purpose tearing and micro-perforations4 for very fine lines. The choice depends on the material and the desired tear effect for the final product.

The 'tooth profile' is about the shape and spacing of the cutting teeth. This is not just a technical detail. It decides exactly how the package will tear. I often tell my clients to think of it like the tread on a tire. You need the right tread for the right road. In the same way, you need the right tooth profile for the right material.

Let's look at some of the most common profiles.

Standard Perforation

This is the most common type. It has uniform cuts and lands (the uncut spaces). The ratio of the cut length to the land length decides how easily the material tears. For example, a 3 TPI (Teeth Per Inch) profile gives 3 cuts and 3 lands per inch. This creates a sturdy but easy-to-tear line. It is perfect for coupon tear-offs or box lids.

Micro-Perforation

This profile has many very small teeth and lands packed closely together. For example, a 72 TPI profile creates a very fine line of tiny holes. This is often used for breathable films for fresh vegetables or for high-security paper applications. It allows air to pass through but keeps the package strong. It gives a very clean, straight tear.

Conclusion

Perforating knives are vital in the packaging industry. They offer huge benefits to manufacturers through production efficiency and to consumers by creating simple, easy-to-open packaging for products we use every day.