Struggling with inconsistent cuts or premature blade wear? The problem might not be the edge, but the mounting holes. Understanding their role is key to improving performance and saving money.

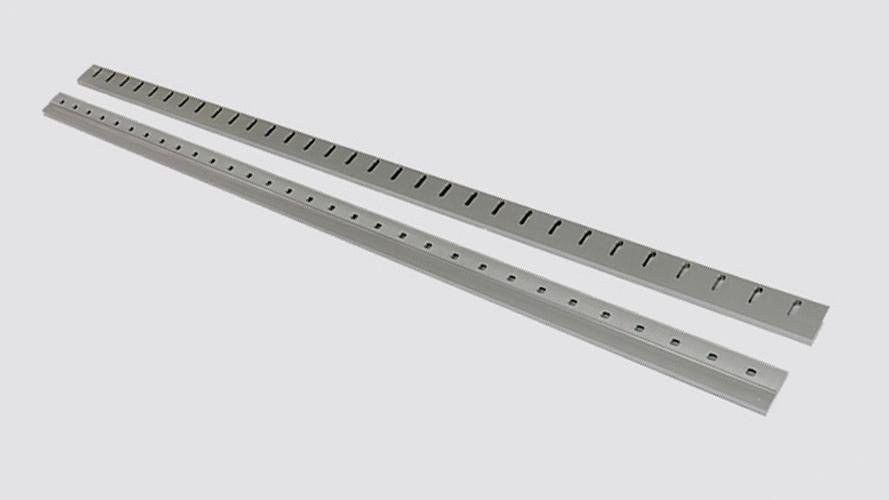

The mounting holes on a guillotine shear blade1 are critical because they ensure precise positioning, stability, and even force distribution. They act as the foundation for the entire cutting process. Poorly made or worn holes lead to misalignment, vibration, poor cut quality, and potential equipment damage.

It seems simple enough. The holes are just there to bolt the blade onto the machine. A guillotine shear blade is only as good as its mounting, and the holes are the direct connection between the blade's power and the machine's stability. Let’s explore why they deserve your full attention.

What Types Of Mounting Holes Do Guillotine Shear Blades Have?

Are you choosing a new blade but feel confused by the different mounting hole options? Picking the wrong type can cause a poor fit, instability, and even damage your machine.

Guillotine shear blades feature several types of mounting holes, including round, oval, threaded, and countersunk. Each design serves a specific function for alignment, fastening, or adjustment. Choosing the correct type ensures a perfect and secure match with your specific cutting machine.

When we manufacture a blade, the mounting holes are just as important as the cutting edge. They must perfectly match the machine's design to function correctly. I've worked with many customers to find the exact hole configuration they need. The choice depends entirely on the machine's model and the cutting application. Here is a simple breakdown of the most common types.

A Guide To Common Hole Types

| Hole Type | Description | Primary Use |

|---|---|---|

| Round Hole | The most common type, a simple circular hole. | Standard fastening, providing precise location and stability. |

| Oval/Slotted Hole | An elongated hole that allows for minor adjustments. | Machines that require fine-tuning of the blade position. |

| Countersunk Hole | A cone-shaped opening that allows the screw head to sit flush or below the surface. | Prevents interference with the material being cut. |

| Threaded Hole | A hole with internal threads to accept a bolt directly. | Secures the blade without needing a nut on the other side. |

| Custom Hole | Uniquely shaped holes designed for specific, non-standard machines. | Proprietary or highly specialized cutting equipment. |

Choosing the right type isn't just about fit. It’s about functionality. A countersunk hole2 is essential in applications where the material must slide smoothly over the blade surface. An oval hole3 can be a lifesaver when you need to make tiny adjustments to the blade clearance. At PASSION, we have the technology to create any hole type with extreme precision, ensuring our blades integrate perfectly with your equipment.

How Do Mounting Holes Directly Impact Cutting Precision?

Are you getting angled cuts, burrs, or inconsistent results from your shear? You checked the blade sharpness and clearance, but the problem persists, costing you time and valuable material.

Mounting holes are the blade's primary positioning reference. An error as small as 0.02mm in hole location can cause blade misalignment4 and uneven clearance. This directly leads to skewed cuts, burrs, and material tearing, destroying the cutting precision required for high-quality products.

Think of the mounting holes as the anchor points for the entire cutting operation. If these anchors are even slightly out of place, the blade will not sit parallel to the other blade or the machine bed. This tiny misalignment creates a domino effect. The clearance between the top and bottom blades becomes uneven along the cutting length. One end might be perfect, but the other might be too tight or too loose. This is where cutting problems begin.

I remember working with a client, Esteban from Mexico, who runs a precision sheet metal fabrication shop. He was getting inconsistent cuts on thin stainless steel sheets. His team had tried everything—sharpening the blades, adjusting the clearance—but the problem remained. He sent me one of his blades from another supplier. Our engineers inspected it and found that the mounting holes were off-center by just 0.05mm. It was a tiny error, but on a 2-meter blade, it was enough to cause the blade to flex and twist during the cut. We manufactured a new blade for him, paying extreme attention to the hole location and tolerances. The problem disappeared immediately. Esteban’s story shows that precision isn't just about the blade's edge; it starts with how the blade is mounted.

What Are The Risks Of Using Blades With Damaged Or Poorly Made Holes?

Have you ever been tempted to reuse a blade with slightly worn mounting holes just to save a little money? This small compromise can lead to serious failures, risking your machine and operators.

Using blades with damaged or low-quality holes creates stress concentration5 points. During a high-impact cut, this can cause the blade to crack or the bolts to shear. This leads to poor cut quality, a much shorter blade life, and significant safety hazards in the workplace.

When a blade cuts through metal, it experiences immense force. This force is transferred from the blade, through the mounting holes, and into the machine frame. If the holes are perfectly round, smooth, and correctly sized, the stress is distributed evenly around each bolt. However, if a hole is worn, oval-shaped, or has a rough surface, it creates a point of weakness. All that cutting force focuses on that one weak spot. This is called stress concentration.

This is a dangerous situation. It’s like having a small crack in your car's windshield. At first, it’s not a big deal. But over time, every bump in the road puts stress on that crack until it suddenly spreads across the entire windshield. The same thing happens with a damaged mounting hole. Each cut sends a shockwave of force into that weak point. Eventually, a microscopic crack can form. This crack can grow with each cut until the blade fails completely, often snapping near the hole. A broken blade can damage your machine’s blade holder and create a massive safety risk for anyone nearby. For this reason, you should always inspect mounting holes for wear or damage before installing a blade. It is a small step that prevents big problems.

Conclusion

Mounting holes are not just for attachment; they are vital for precision, safety, and performance. Always inspect them carefully to ensure your cutting operations run smoothly and efficiently.

Learn about the essential features that contribute to effective cutting performance. ↩

Understanding their function can enhance material handling during cuts. ↩

Discover how oval holes can improve blade adjustments and performance. ↩

Identifying causes can help prevent costly production errors. ↩

Understanding stress concentration can help prevent blade failures. ↩