Inconsistent cuts and product quality are frustrating. This waste costs money and time. Understanding blade tolerance1 is the key. It ensures every cut is precise, protecting your products and equipment.

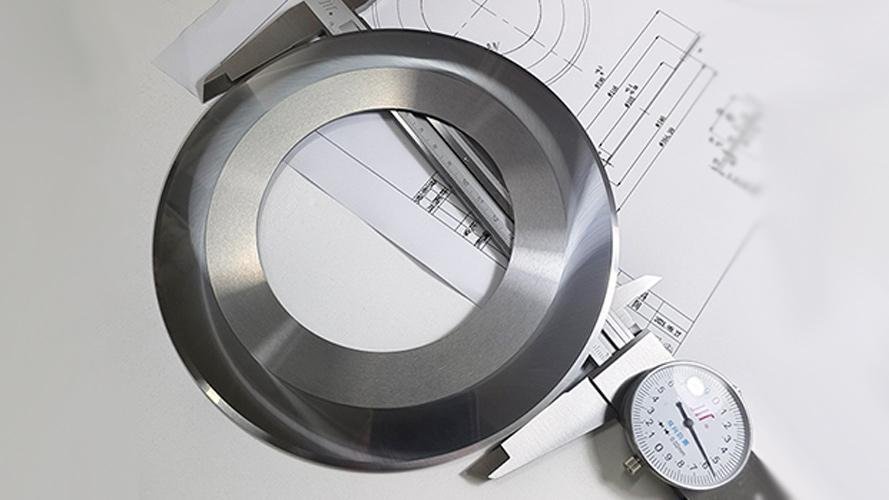

Blade tolerance is a critical parameter measuring manufacturing precision. It directly affects cutting accuracy, blade lifespan, equipment stability, and product consistency. Proper tolerance ensures blades fit perfectly and perform reliably, preventing defects.

A tiny deviation in a blade's size can cause huge problems on a production line. It's a detail many people overlook until something goes wrong. But once you understand how tolerance works, you can avoid these issues completely. Let's explore some common questions I hear from customers to help you get a clearer picture.

Does A Tighter Tolerance Always Mean Better Cost-Effectiveness?

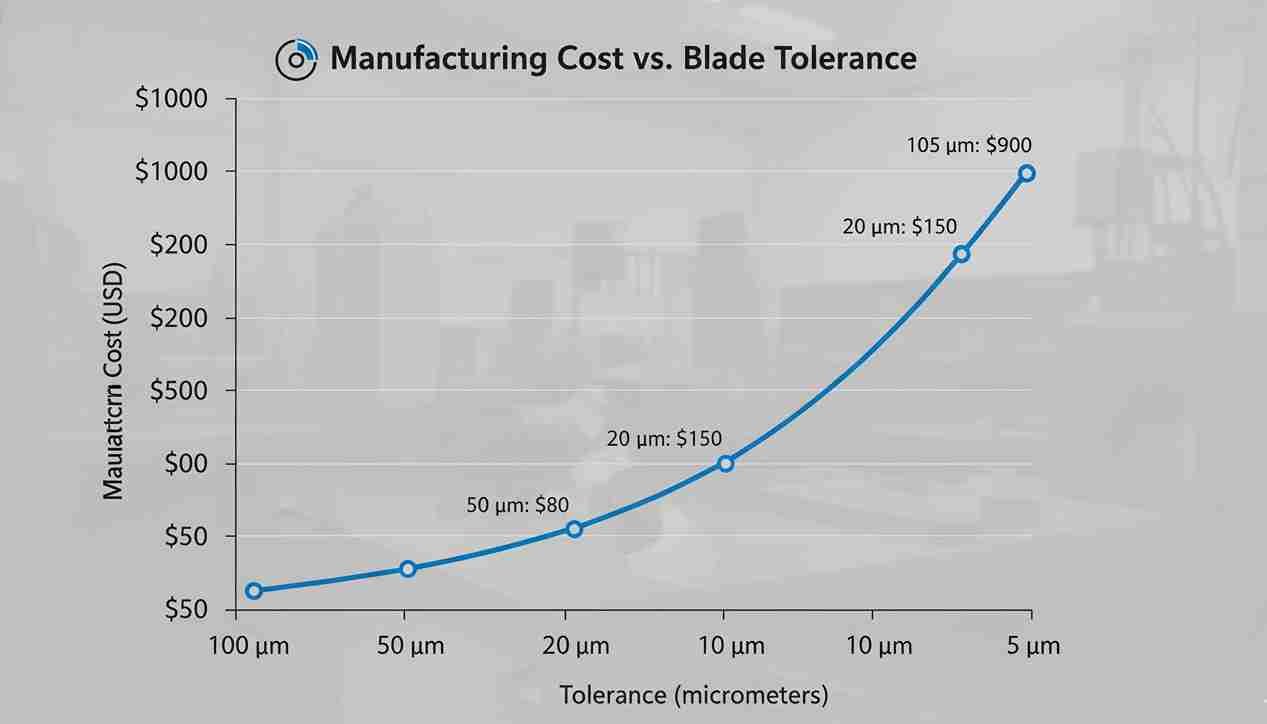

You believe the tightest tolerance is always best. It seems logical to aim for maximum precision. But this can skyrocket costs without adding real value, hurting your budget.

No, a tighter tolerance does not always mean better cost-effectiveness. Extremely tight tolerances require complex manufacturing and stricter quality control, which significantly increases the blade's price. The optimal choice balances necessary precision with a reasonable budget.

I remember a client, Mark from a packaging company, who insisted on the tightest possible tolerances for a simple cardboard cutting application. He thought it would guarantee the best results. However, the blades were very expensive. After we talked, I explained that his machine and material didn't require that level of precision. We switched to a standard, high-quality PASSION blade with a slightly wider but still very precise tolerance. His costs went down by 30%, and the cutting quality was exactly the same. The key is to find the sweet spot. Over-specifying tolerance is a common mistake that wastes money. We need to consider the application's unique needs to find the right balance between performance and cost.

Finding The Balance

| Factor | Extremely Tight Tolerance | Optimal Tolerance |

|---|---|---|

| Cost | Very High | Moderate |

| Performance | Highest Precision | Sufficient for Application |

| Manufacturing | Long & Complex | Standard & Efficient |

| Best For | Aerospace, medical devices | Most industrial uses |

How Do Tolerances Directly Impact Your Cutting Quality?

Your products have rough edges or uneven cuts. You're facing customer complaints and high rejection rates. This waste costs you money in lost materials and hurts your brand's reputation.

Tolerance directly controls the blade's dimensional consistency. If a blade's thickness, diameter, or flatness is out of spec, it can wobble or be misaligned. This leads directly to poor cutting quality, including burrs, angled cuts, and material damage.

Think about how a blade sits in a machine. It's held by a holder or an arbor. If the blade's inner diameter tolerance is wrong, it will not sit securely. If it's too loose, it will vibrate during rotation. We call this 'runout2'. This vibration3 causes wavy cuts and rough edges. If the blade's thickness is inconsistent, the clearance between blades in a slitting operation will be wrong. This can crush or tear the material instead of cutting it cleanly. I often use a simple analogy: it's like trying to write with a pencil lead that is loose in the pencil. You cannot draw a straight line. The same principle applies to industrial cutting. A precision fit equals precision performance every time.

Key Tolerance Parameters And Their Impact

| Tolerance Parameter | Impact Of Poor Control | Result On Product |

|---|---|---|

| Thickness | Inconsistent blade gap | Crushed edges, incorrect slit width |

| Outer/Inner Diameter | Poor fit on arbor, runout | Vibration, wavy cuts |

| Flatness/Parallelism | Blade wobbles during rotation | Angled cuts, burrs |

Can The Wrong Tolerance Damage Your Equipment?

You are experiencing unexpected machine downtime. Bearings wear out fast, and you hear unusual noises. These repairs are costly and halt production, and you worry about damaging your expensive machinery.

Yes, the wrong tolerance can definitely damage your equipment. A blade that fits too tightly can stress the shaft during installation. A loose-fitting blade causes vibrations that lead to premature wear on bearings, holders, and other machine components.

I worked with a client, a large film manufacturer in Germany. They had frequent breakdowns on their slitting machines. The main issue was bearing failure4. They were buying cheap blades from a local supplier to save on costs. When I visited, I measured their blades. The inner diameter had a very wide tolerance range. Some blades were so loose they rattled on the shaft. Others were too tight and had to be forced on. This imbalance and vibration put immense stress on the machine's bearings, causing them to fail every few months. We replaced their blades with PASSION blades, which have strict tolerance control. The vibrations disappeared immediately. Their machine uptime increased by over 20%, and they have not had a bearing failure since. This shows that investing in quality blades is really an investment in the health of your machinery.

How Tolerance Protects Your Machinery

| Blade Fit Issue | Immediate Effect | Long-Term Damage |

|---|---|---|

| Too Loose (ID) | Vibration, runout, noise | Bearing wear, shaft damage, holder fatigue |

| Too Tight (ID) | Difficult installation | Shaft deformation, stress cracks in blade |

| Uneven Thickness | Unbalanced rotational force | Increased stress on entire drive system |

How Do You Determine The Right Tolerance For Your Application?

You know tolerance is important, but you are not sure how to choose the right one. Choosing the wrong tolerance can lead to poor quality, machine damage, and wasted money.

To determine the right tolerance, first consult your machine's manual for specifications. Then, consider the material being cut and the required finish quality. For high-precision jobs, tighter tolerances are needed. For general cutting, a standard tolerance is often sufficient.

Choosing the right tolerance is about matching the blade to the system. My first step is always to ask about your setup. What machine are you using? What does the manufacturer recommend? We always start there. Next, we discuss the material. Cutting thin film requires much tighter thickness and flatness tolerances than cutting thick cardboard. Then, we talk about the final product. Does it need a perfect, mirror-like edge, or is a standard clean cut okay? This helps us balance precision with cost. At PASSION, we have standard tolerance grades, but we also specialize in creating custom solutions. We can work with you to analyze your process and define the perfect tolerance that gives you the best performance without overspending. It's a partnership to find the most efficient solution.

Key Factors For Choosing Tolerance

| Factor | What To Consider | Example |

|---|---|---|

| Machine Specs | Check the original equipment (OEM) manual. | A slitter requires H7 tolerance for the inner diameter. |

| Material Type | Is it thin/delicate or thick/robust? | Thin plastic film needs tight flatness to avoid wrinkles. |

| Quality Needs | Is the cut edge visible? Is it a functional edge? | Medical tubing requires a perfectly burr-free cut. |

| Budget | Balance the blade's cost with its performance. | For rough cutting, a standard tolerance blade works well. |

Conclusion

Choosing the right blade tolerance is vital for quality, efficiency, and cost. It protects your machines and ensures perfect cuts. At PASSION, we help you find that perfect balance.

Understanding blade tolerance is crucial for ensuring precision in cutting and maintaining product quality. ↩

Learn about runout and its impact on machining accuracy and product quality. ↩

Explore the effects of vibration on cutting quality and how to mitigate its impact. ↩

Understanding the causes of bearing failure can help prevent costly downtime and repairs. ↩