Dull blades and burn marks1 ruining your woodworking projects? This wastes time, material, and money. The right blade material is the solution to these common problems.

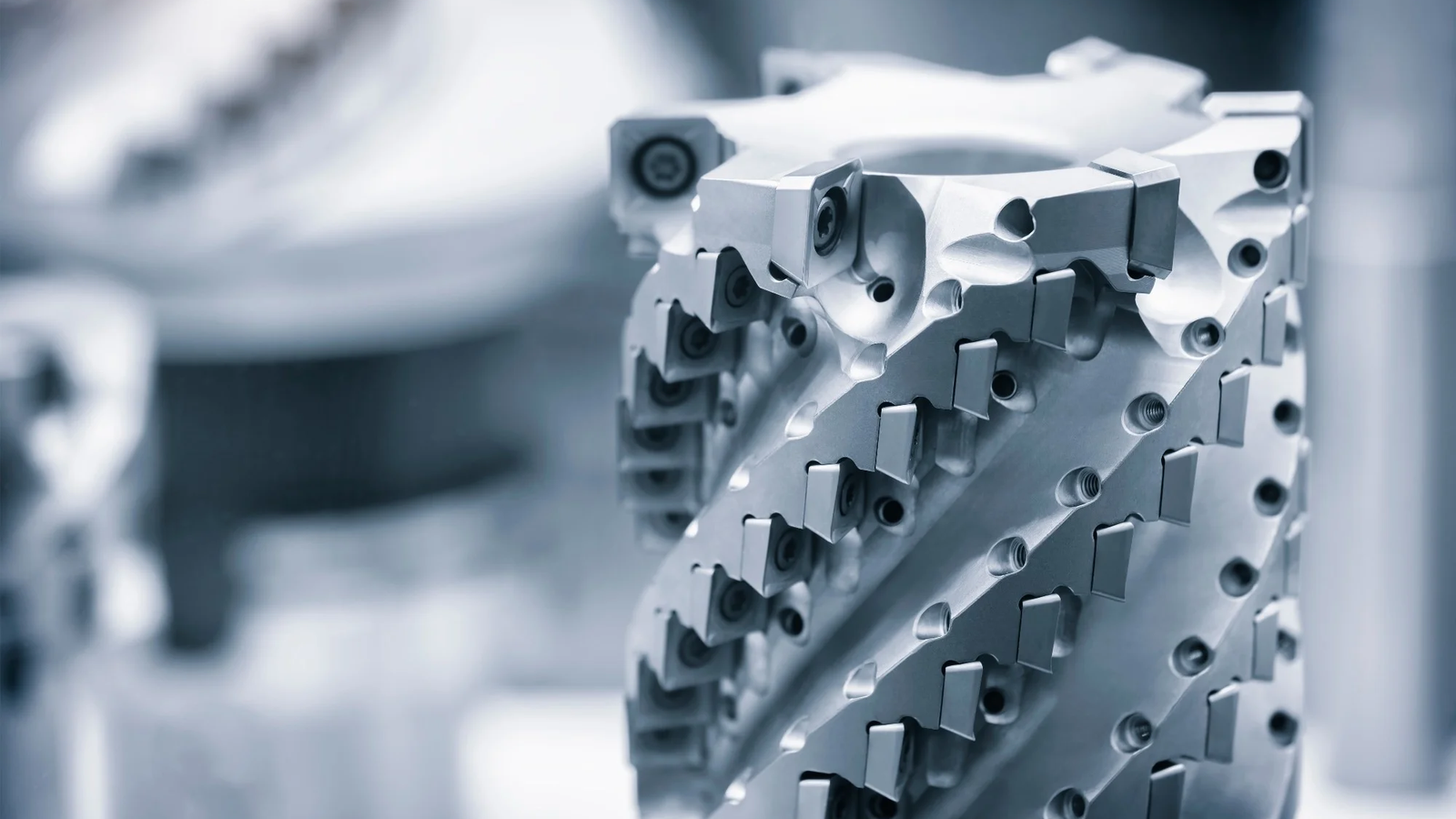

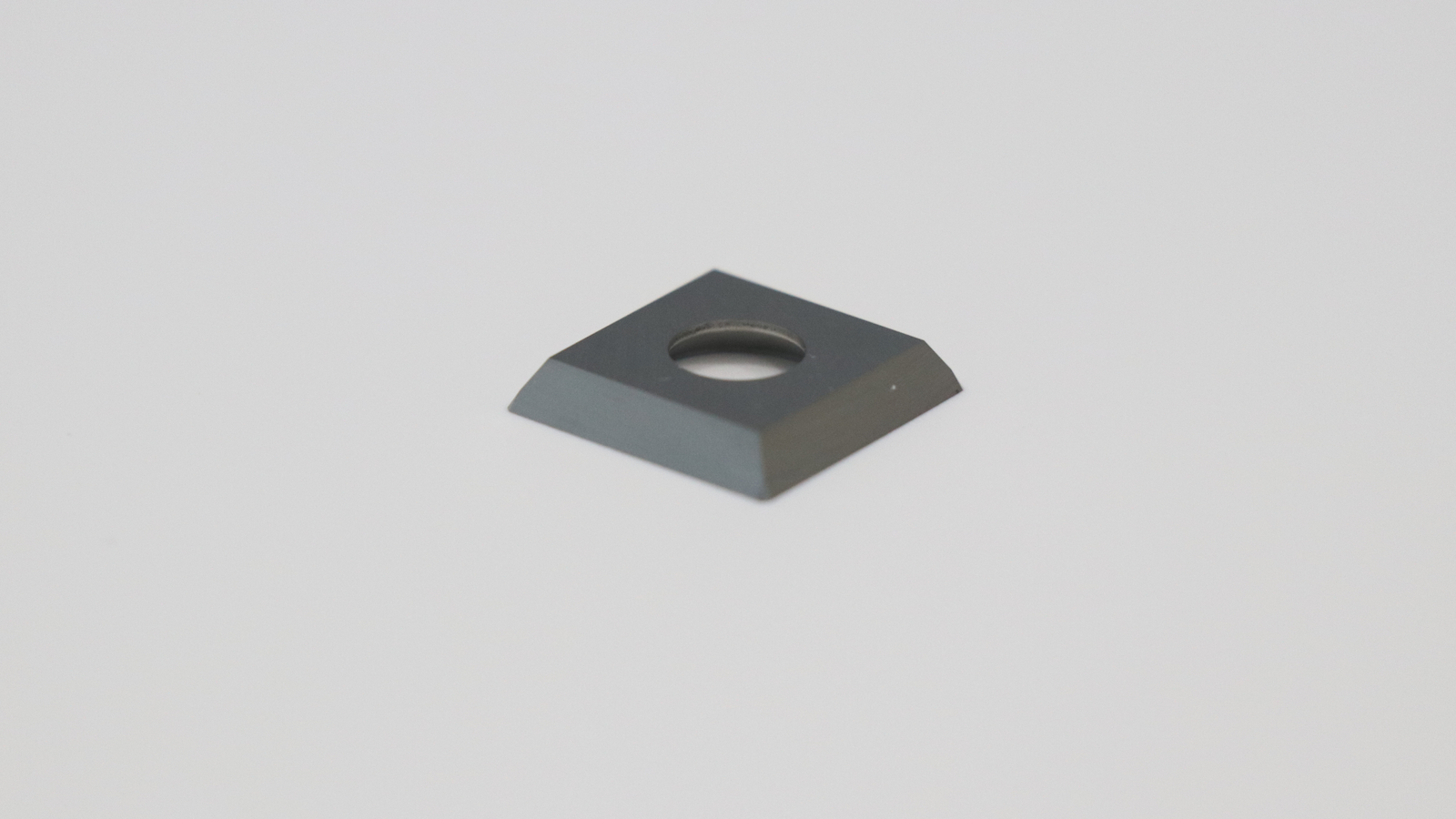

Tungsten carbide blades are the top choice because they can resist heat during high-speed cutting, which prevents burn marks and ensures a clean, precise finish on all types of wood and composite materials.

A while ago, I spoke with Mike, a production manager at a furniture factory in Germany. He had a problem I hear all the time. His standard steel blades were dulling quickly, and worse, they were leaving ugly scorch marks on the wood. He was wasting material and his team was wasting time changing blades. He needed a better solution. His story is a perfect example of why the industry has moved towards tungsten carbide.

So, what exactly makes these blades so special? Let's break it down.

How Do Tungsten Carbide Blades Achieve Such A Long Lifespan?

Constantly changing blades costs you time and money. It slows down your production line. There is a way to drastically reduce this downtime and keep working efficiently.

Tungsten carbide blades last longer because their exceptional hardness resists wear from abrasive materials2 found in wood and glues. They are over twice as hard as high-speed steel, allowing them to stay sharp for much longer, even when cutting tough composite boards.

When we think about cutting wood, we often forget what's inside it. Wood isn't just soft fiber. Natural wood contains abrasive elements like lignin and silicates. These act like fine sandpaper, slowly wearing down a blade's edge. The problem gets much worse with man-made boards like MDF or particleboard. These materials are held together with extremely hard and abrasive glues, like melamine formaldehyde resin. A standard steel blade just can't stand up to this constant friction. This is why Mike had to change his blades so often. For him, tungsten carbide was the answer because it is one of the hardest materials available. Its ability to resist this abrasive wear means it can cut for hundreds of hours before needing to be sharpened. This dramatically increases uptime and lowers the cost per cut.

The Enemies Of A Sharp Edge

| Feature | Tungsten Carbide (WC) | High-Speed Steel (HSS) |

|---|---|---|

| Hardness (HRA) | 90 - 93 | ~65 - 70 |

| Lifespan vs HSS | 10x - 20x longer | Baseline |

| Best For | Abrasive materials, composites, long runs | Natural softwoods, general purpose |

What Is "Red Hardness" And Why Does It Prevent Burn Marks On Wood?

Do you see ugly scorch marks on your cut edges? This friction burn is a clear sign your blade is failing under heat. It’s a common but fixable problem.

"Red hardness" is a material's ability to stay hard even when it gets red-hot from cutting friction. Tungsten carbide excels here, maintaining its hardness at 800°C. This prevents the cutting edge from softening and dulling, which eliminates the friction that causes burn marks.

High-speed cutting creates a huge amount of friction, and friction creates heat. This heat is focused on the tiny cutting edge of the blade. A traditional steel blade will begin to soften when it gets too hot. A soft edge is a dull edge. Once the blade is dull, it stops cutting cleanly and starts rubbing against the wood. This rubbing action creates even more friction and more heat, which quickly leads to the black scorch marks Mike was seeing on his furniture parts. This was his biggest frustration. Tungsten carbide solves this problem completely. It has excellent "red hardness3," which is just a technical way of saying it stays incredibly hard even at extreme temperatures. So, while a steel blade is softening and failing, a carbide blade continues to cut cleanly. It breaks the cycle of dulling, rubbing, and burning. The result is a smooth, clean surface, even after long and fast cuts.

The Science Behind A Clean Cut

The process is a vicious cycle for steel blades.

- High Speed: Normal operation creates friction and heat.

- Steel Softens: The blade edge loses its hardness due to the heat.

- Edge Dulls: A soft edge can no longer hold its sharpness.

- Blade Rubs: The dull edge plows and rubs instead of slicing.

- More Friction: Rubbing creates intense heat, burning the wood.

Tungsten carbide's red hardness keeps it sharp at stage 2, preventing the rest of the cycle from ever starting.

How Does The Material Itself Guarantee A Cleaner, More Precise Cut?

Are your cuts fuzzy with tear-out? Do your joints not fit together perfectly? The problem might not be your machine, but the stability and sharpness of your blade's cutting edge.

Tungsten carbide's fine grain structure and high stiffness allow us to grind an extremely sharp and stable cutting edge. This sharp edge cleanly severs wood fibers instead of tearing them. Its rigidity also prevents flexing during the cut, ensuring perfect dimensional accuracy4 for projects like cabinets.

A quality cut is about more than just avoiding burns. It's about precision. Think about cutting a tomato with a sharp knife versus a dull one. The sharp knife slices through cleanly, while the dull one crushes and tears it. It's the same with wood fibers. Because tungsten carbide is so hard, we can grind it to an incredibly sharp and fine edge. This edge slices through wood fibers cleanly, leaving a smooth surface with no splintering or "tear-out." The material is also extremely stiff, or rigid. This means the blade won't flex or bend, even when cutting through dense hardwood. This rigidity ensures that every cut is perfectly straight and dimensionally accurate. For someone like Mike, who makes high-quality furniture, this is critical. His cabinet doors need to fit perfectly and his joints need to be seamless. The switch to our carbide blades gave him the precision his final products required, reducing assembly time and improving the overall quality.

Cutting Vs. Tearing

- Sharp Carbide Edge: Acts like a scalpel. It cleanly severs individual wood fibers. This results in a smooth, almost polished surface that is ready for finishing.

- Dull or Soft Steel Edge: Acts like a blunt instrument. It tears and rips the fibers apart. This creates a fuzzy, splintered surface that requires extra sanding and rework. The high rigidity5 of carbide ensures this sharp edge is delivered consistently through the entire cut.

Conclusion

Tungsten carbide blades offer unmatched longevity, heat resistance, and precision. They are a smart investment for any serious woodworker looking to improve both efficiency and quality.

Learn about the causes of burn marks and how to prevent them for cleaner cuts in your woodworking. ↩

Gain insights into abrasive materials and their effects on blade wear to make informed choices. ↩

Learn about red hardness and its significance in maintaining blade performance during high-temperature cutting. ↩

Explore the concept of dimensional accuracy and its role in ensuring high-quality woodworking projects. ↩

Explore the benefits of high rigidity in cutting tools for maintaining precision during cuts. ↩