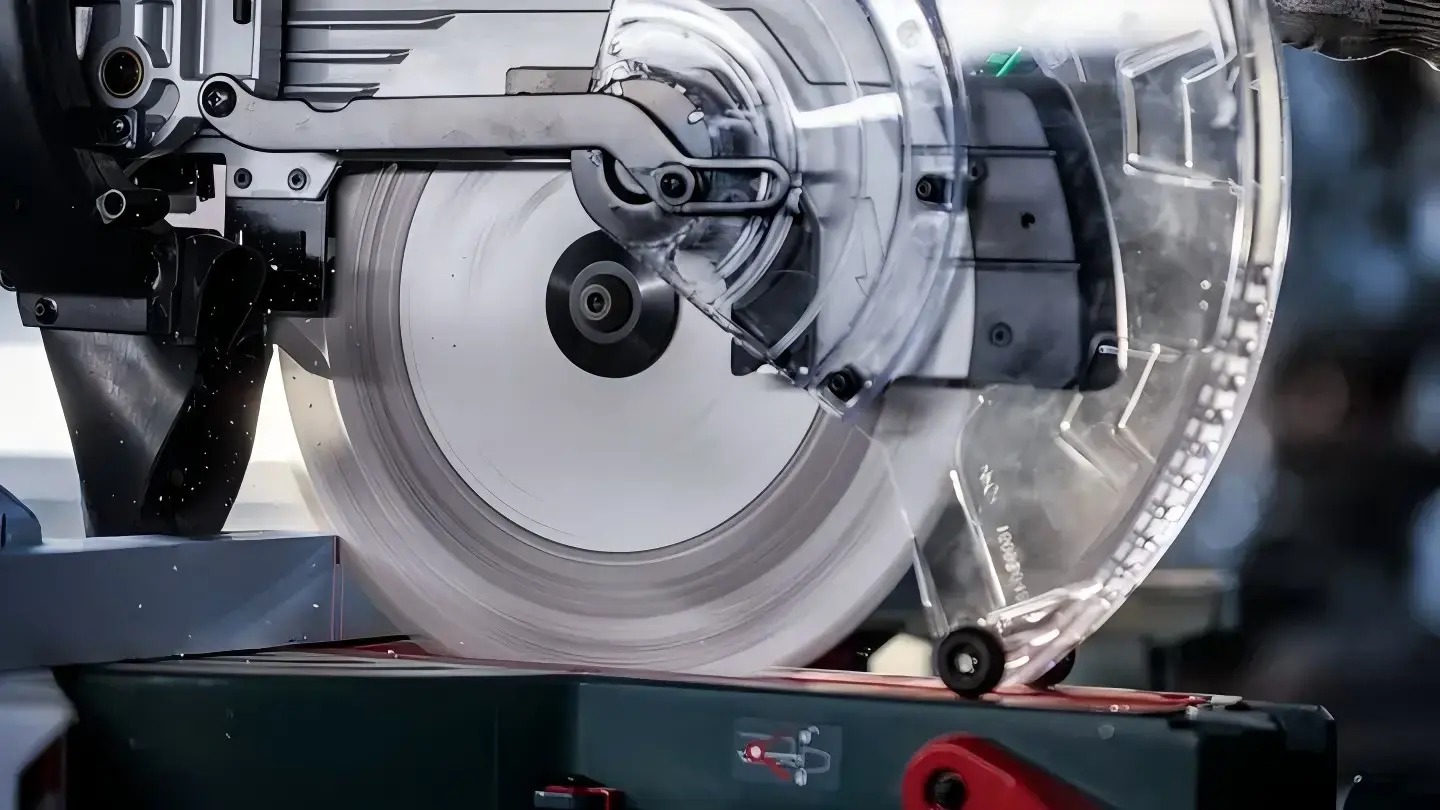

Struggling with slow cutting speed1s and frequent blade changes? This downtime hurts your productivity and profit. The right blade material is the simple solution you need to get ahead.

Tungsten carbide2 and silicon carbide3 blades cut faster mainly due to their superior "hot hardness4." They maintain their strength and sharp edge at extreme temperatures over 1000°C. In contrast, high-speed steel (HSS)5 softens around 600°C, which limits its cutting speed.

Choosing the right blade material can feel complicated. I often explain that it's not just about which material is "best," but which is best for a specific job. High cutting speed is a common goal for many industries I work with, from packaging to metalworking. When speed is the priority, the science points clearly toward carbide materials. Let's break down exactly why these advanced materials leave traditional HSS behind when the machines are running full throttle.

How Does Hot Hardness Allow For Faster Cutting Speeds?

Are your blades failing when you try to increase production speed? The intense heat generated might be softening the cutting edge. This leads to poor cuts and unexpected tool failure. Hot hardness allows a blade to stay hard even when it gets extremely hot from friction during cutting.

Digging Into "Red Hardness"

When we talk about hot hardness in the industrial blade industry, we often call it "red hardness." This is because metals glow red at the high temperatures where this property becomes critical. If a blade material loses its hardness when it glows red, it cannot cut effectively at high speeds. This is exactly what happens with HSS.

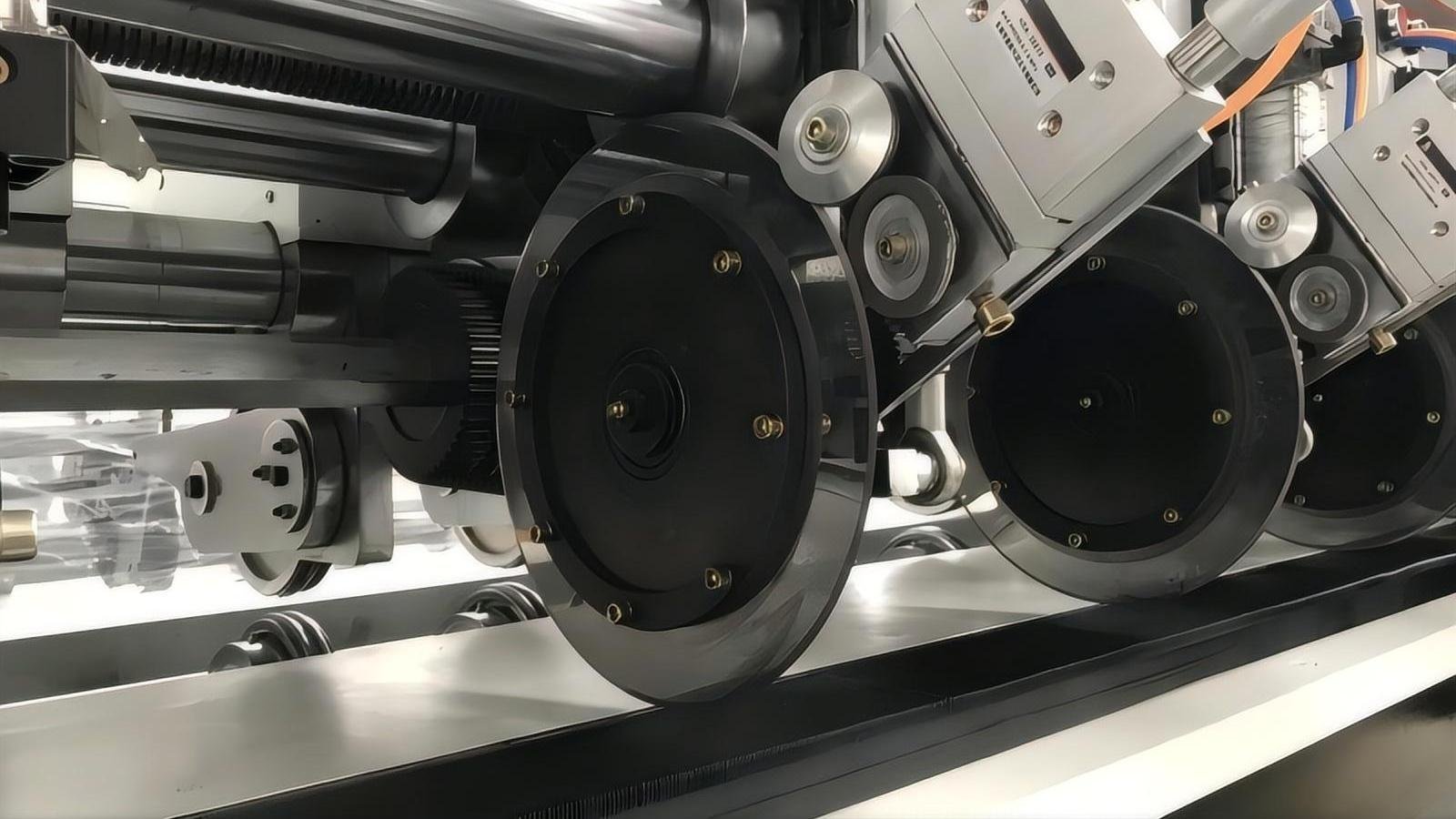

When a machine runs faster, it generates more friction and heat. Tungsten carbide and silicon carbide tooling can handle this intense heat without deforming or becoming dull. This allows you to increase machine RPMs6 and feed rates7 significantly. The blade keeps cutting cleanly, while an HSS blade would have failed long ago. This directly translates to higher output and better efficiency.

| Material | Softening Temperature (Approx.) | Performance Implication |

|---|---|---|

| High-Speed Steel (HSS) | ~600°C | Limited to lower speeds to manage heat. |

| Tungsten Carbide (TC) | >1000°C | Excellent for high-speed continuous cutting. |

| Silicon Carbide (SiC) | >1200°C | Superior performance in extreme heat applications. |

This ability to withstand extreme temperatures is the main reason you can push carbide blades much faster.

Why Does Overall Hardness Matter More Than Just Sharpness?

Is a freshly sharpened blade dulling almost immediately on a tough job? A sharp edge means nothing if it cannot last. That frequent downtime for blade changes is a production killer.

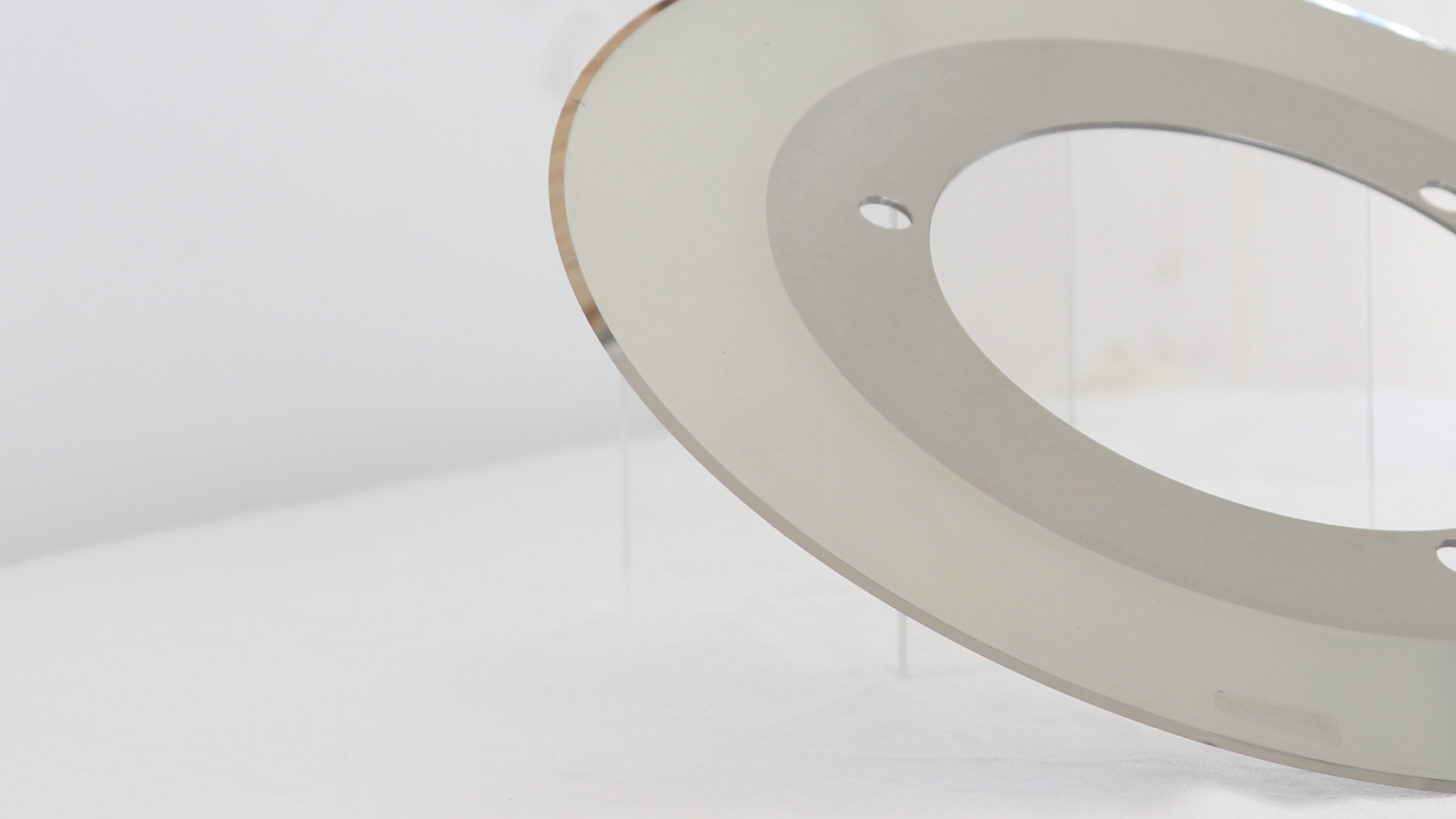

While HSS is quite hard, tungsten and silicon carbides are on another level. This superior base hardness means they resist abrasive wear much better. Their cutting edges stay sharp for far longer under high-speed stress, providing more consistent cuts and dramatically reducing downtime.

Edge Retention Is Key To Productivity

A sharp blade is only useful if it stays sharp. This property is called edge retention8. A material with higher hardness has better edge retention, because it can better resist the abrasive forces that try to wear the edge down. Imagine trying to scratch a diamond with a piece of steel; it just won't work. The same principle applies here.

I remember working with a client, who runs a large packaging plant in Europe. He was using HSS blades on his film-cutting lines and had to change them three times per shift. This was causing major bottlenecks. After discussing his process, I recommended tungsten carbide blades. He was hesitant about the initial cost, but decided to try them. The result? He now changes blades once every two weeks. His line speed increased by 30%, and the cut quality is perfect. This is a real-world example of how superior hardness directly boosts productivity by keeping the edge sharp for longer.

| Material | Hardness (Vickers HV) | Key Advantage |

|---|---|---|

| High-Speed Steel (HSS) | ~800-900 HV | Good balance of toughness and hardness. |

| Tungsten Carbide (TC) | ~1500-2400 HV | Extreme hardness and wear resistance. |

| Silicon Carbide (SiC) | ~2500-3500 HV | Among the hardest materials available. |

This data shows why a carbide edge simply lasts longer, allowing for faster and more continuous operation.

What Role Does Thermal Stability Play In Continuous Cutting?

Have you noticed your cutting accuracy decreasing during long, continuous jobs? Your blade might be expanding from heat. This subtle change can ruin precision and waste valuable material.

Thermal stability refers to how little a material expands or changes shape when it gets hot. Carbide materials have a very low coefficient of thermal expansion. This means the blade’s precise geometry remains stable even at high speeds, ensuring every cut is as accurate as the first.

Why Blade Shape Consistency Matters

In many industries I serve, like plastics, textiles, and paper, precision is everything. If a blade expands even a fraction of a millimeter because of heat buildup, it can cause the cut to go out of tolerance. This can lead to rejected products and wasted material.

HSS expands more than carbide when it gets hot. In long, continuous cutting applications, this expansion can alter the blade's cutting angle and clearance, leading to a drop in cut quality. Since carbide blades are far more stable, they hold their exact shape. This geometric stability ensures that the cutting action remains consistent from the beginning of a production run to the end. For operations that run 24/7, this stability is not just a small bonus; it is essential for maintaining product quality and minimizing scrap. It allows for a "set it and forget it" process, which is what every production manager wants.

| Material | Thermal Expansion (10⁻⁶/K) | Implication for Precision |

|---|---|---|

| High-Speed Steel (HSS) | ~12.0 | Higher expansion can affect tolerance in long runs. |

| Tungsten Carbide (TC) | ~5.0 - 6.0 | Very stable, maintains shape under heat. |

| Silicon Carbide (SiC) | ~4.0 - 4.5 | Extremely stable, ideal for high-precision tasks. |

This stability is the final piece of the puzzle, guaranteeing that the speed you gain from carbides doesn't come at the cost of precision.

Conclusion

Carbide blades excel due to superior hot hardness for speed, overall hardness for durability, and thermal stability9 for precision. This combination ensures faster, longer, and more accurate cutting operations.

Find strategies to enhance cutting speed and improve productivity in manufacturing. ↩

Explore the advantages of Tungsten carbide blades for cutting, including speed and durability. ↩

Learn how silicon carbide blades outperform others in high-temperature applications. ↩

Understand the significance of hot hardness in maintaining cutting efficiency. ↩

Discover the drawbacks of HSS blades and why they may not be suitable for high-speed cutting. ↩

Understand how RPMs impact cutting performance and productivity. ↩

Learn how adjusting feed rates can enhance cutting efficiency and output. ↩

Explore the key factors that influence edge retention and tool longevity. ↩

Learn about the importance of thermal stability in maintaining cutting precision. ↩