Confused by the wide price range for seemingly identical blades? Choosing a cheap option can lead to costly downtime and material waste. I'll explain what truly drives the price difference.

The price of tungsten carbide blades varies due to the quality of raw materials (virgin vs. recycled), the specific alloy grade, the complexity of the manufacturing process, precision standards, and the application of special coatings. A higher price often indicates superior materials and engineering for better performance.

I get this question all the time from customers. It's frustrating to see two blades that look the same on paper but have vastly different price tags. The truth is, what you can't see is what you're paying for. The differences are hidden in the raw materials, the manufacturing floor, and the microscopic details of the blade's edge. Let's break down these factors one by one so you can see why a higher price can actually save you money in the long run.

Virgin Vs. Recycled Powder: What's The Real Difference In Cost And Quality?

Worried you might be overpaying for a "premium" material? Using the wrong powder can cause your blades to fail prematurely, halting production. The choice between virgin and recycled powder1 is critical.

Virgin tungsten carbide powder is pure and consistent, leading to reliable, high-performance blades. Recycled powder is cheaper but contains impurities and inconsistencies that compromise a blade's strength and lifespan, making it less dependable.

I once had a client who bought a batch of cheap slitter knives for his plastic film converting business. He said they looked exactly like the ones we offered but were 40% cheaper. Within a week, he called me. The blades were chipping and wearing out three times faster than he expected, causing jagged cuts and expensive line stoppages. This is a classic case of what happens when you compare blades based on looks and price alone. The unseen difference was almost certainly the raw material.

We know that the foundation of a great blade is great material. That's why the distinction between virgin and recycled powder is so important.

The Purity Of Virgin Tungsten Carbide Powder

Think of this as cooking with the freshest, highest-quality ingredients. Virgin powder is made from scratch. This process gives us total control over its purity and the size of the microscopic grains.

- High Purity: It's free from contaminants that can create weak spots in the final blade.

- Consistent Grain Size: Uniform grains create a dense, strong structure. This means the blade has predictable hardness and toughness, so it performs reliably every single time. This is what results in a blade that holds its sharp edge longer and resists chipping under stress. It costs more to produce, but the performance and reliability are unmatched.

The Compromise Of Recycled Tungsten Carbide Powder

Recycled powder, or reclaimed powder, is made from scrap tungsten carbide. Old tools, worn-out blades, and manufacturing waste are ground down and reprocessed. While this is great for the environment and lowers costs, it comes with trade-offs.

- Potential Impurities: The recycling process can introduce foreign materials or create inconsistencies in the chemical composition.

- Irregular Grain Structure: The grains are often damaged or non-uniform, which can lead to a less stable internal structure. A blade made from recycled powder might perform well initially, but it is far more likely to fail unexpectedly. The weak points can lead to micro-fractures, causing the edge to dull or chip much faster. It's a gamble that often doesn't pay off in a high-production environment.

| Feature | Virgin Powder | Recycled Powder |

|---|---|---|

| Cost | Higher | Lower |

| Purity | Very High | Variable, Lower |

| Performance | Consistent, Reliable | Inconsistent |

| Blade Lifespan | Longer | Shorter |

| Best For | High-demand, precision applications | Low-demand, non-critical tasks |

So when you see a very cheap blade, you need to pay attention to whether it is made from recycled powder. For us, a blade is a critical component for our customers' success. That's why we primarily use high-grade virgin powder to ensure every cut is precise and every blade lasts as long as possible.

How Do Manufacturing Processes And Precision Standards Affect Blade Costs?

Does a small imperfection in a blade really matter? A blade that isn't perfectly flat or straight can cause machine vibrations and poor cuts. Top-tier manufacturing is expensive but essential for quality.

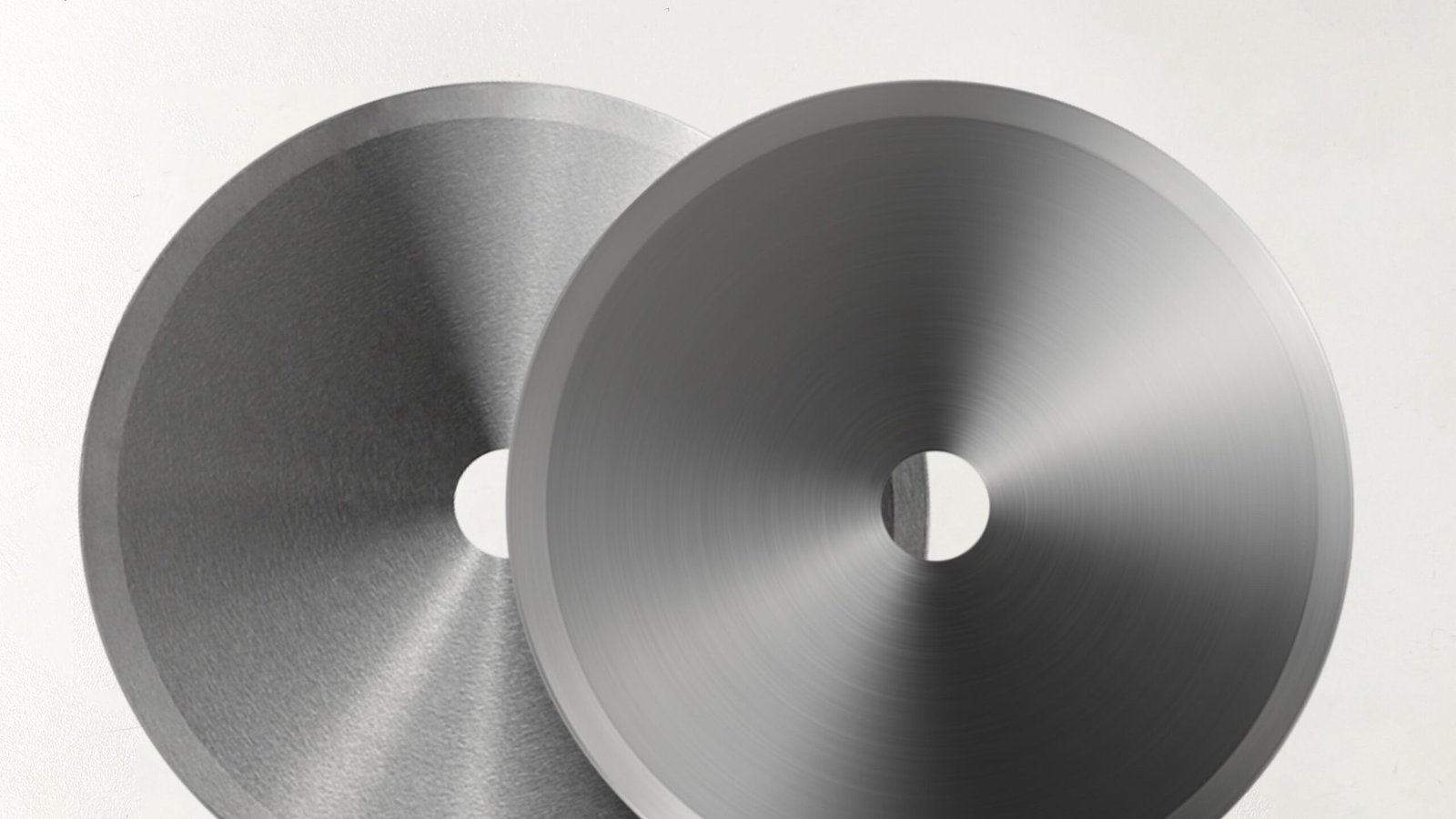

Advanced manufacturing like Cold Isostatic Pressing2 (CIP) and precision grinding creates highly uniform and stable blades. Stricter tolerances (e.g., straightness, parallelism) ensure perfect cuts but require more time and expensive machinery, increasing the cost.

Think of it like building a high-performance car engine. You can have the best metal alloys, but if the parts aren't machined to exact specifications, the engine will run poorly or even break down. The same is true for industrial blades. An excellent raw material is just the starting point; the manufacturing journey it goes through is what truly defines its quality and, therefore, its price. Many of our customers in the packaging and paper industries tell us that switching to a high-precision blade reduced machine maintenance costs significantly.

The Art Of Manufacturing A Blade

Creating a top-tier tungsten carbide blade is a multi-stage process where every step counts. Cheaper blades often come from factories that cut corners on these critical steps.

- Powder Mixing and Pressing: We carefully blend the tungsten carbide powder with a binder like cobalt. Then, instead of simple die pressing, we use Cold Isostatic Pressing (CIP). This involves applying equal pressure from all directions, which creates a "green" part that is incredibly dense and uniform. This step prevents internal weak spots.

- Sintering: The pressed part is heated in a vacuum furnace to just below its melting point. This fuses the particles together into a solid, hard mass. Doing this in a vacuum is crucial because it removes all air and prevents oxidation, which could weaken the blade. Cheaper processes might not use a full vacuum, leading to a less durable product.

- Precision Grinding: After sintering3, the blade is ground to its final shape and dimensions. This is where precision becomes paramount. We use computer-controlled (CNC) grinding machines that cost millions of dollars. These machines can achieve microscopic levels of accuracy, creating an edge that is not just sharp, but perfectly straight and smooth.

Why Precision Tolerances Matter

When we talk about "precision" or "tolerances," we mean specific measurements like thickness, flatness, and parallelism. For a premium blade, these tolerances might be as small as ±0.001mm.

- Thickness & Parallelism: If a long slitter knife isn't perfectly parallel along its entire length, the cutting gap will be inconsistent. This leads to burrs, uneven cuts, and puts stress on the blade and machine bearings.

- Flatness & Straightness: A blade that isn't perfectly flat or straight will wobble at high speeds. This vibration not only ruins the cut quality but also causes premature wear on the blade and the machine itself.

Achieving these tight tolerances requires more machine time, highly skilled operators, and frequent quality control checks. All of this adds to the cost. A low-cost blade might have tolerances that are 5 or 10 times looser. It might look fine to the naked eye, but in a high-speed industrial machine, that small difference has a huge impact on performance and operational costs.

Are Coatings And Customization Worth The Extra Cost For Industrial Blades?

Do you really need a special coating or a custom-sized blade? Sticking with a standard, uncoated blade can cause issues like material buildup and inefficiency. These upgrades are not just features; they're solutions.

Coatings like TiN or TiAlN increase a blade's surface hardness and reduce friction, extending its life and improving cut quality, especially with sticky materials. Customization creates the perfect blade for a specific task, justifying the higher unit cost.

A few years ago, I collaborated with a food processing company in the United States that was cutting sticky granola bars. Their standard uncoated blades were getting gummed up with sugar and residue, forcing them to stop the line for cleaning every hour. It was a major bottleneck. We suggested a blade with a mirror polish and a specialized non-stick coating. The extra cost per blade seemed high at first. However, they soon found that they could run the line for a full 8-hour shift without stopping. The return on investment was huge. This is a perfect example of how "extras" like coatings and custom solutions aren't just costs—they are investments in efficiency.

The Power 0f Surface Coatings

A coating is a micro-thin layer of ceramic material applied to the blade's surface. It's not just for looks; it fundamentally changes how the blade interacts with the material it's cutting.

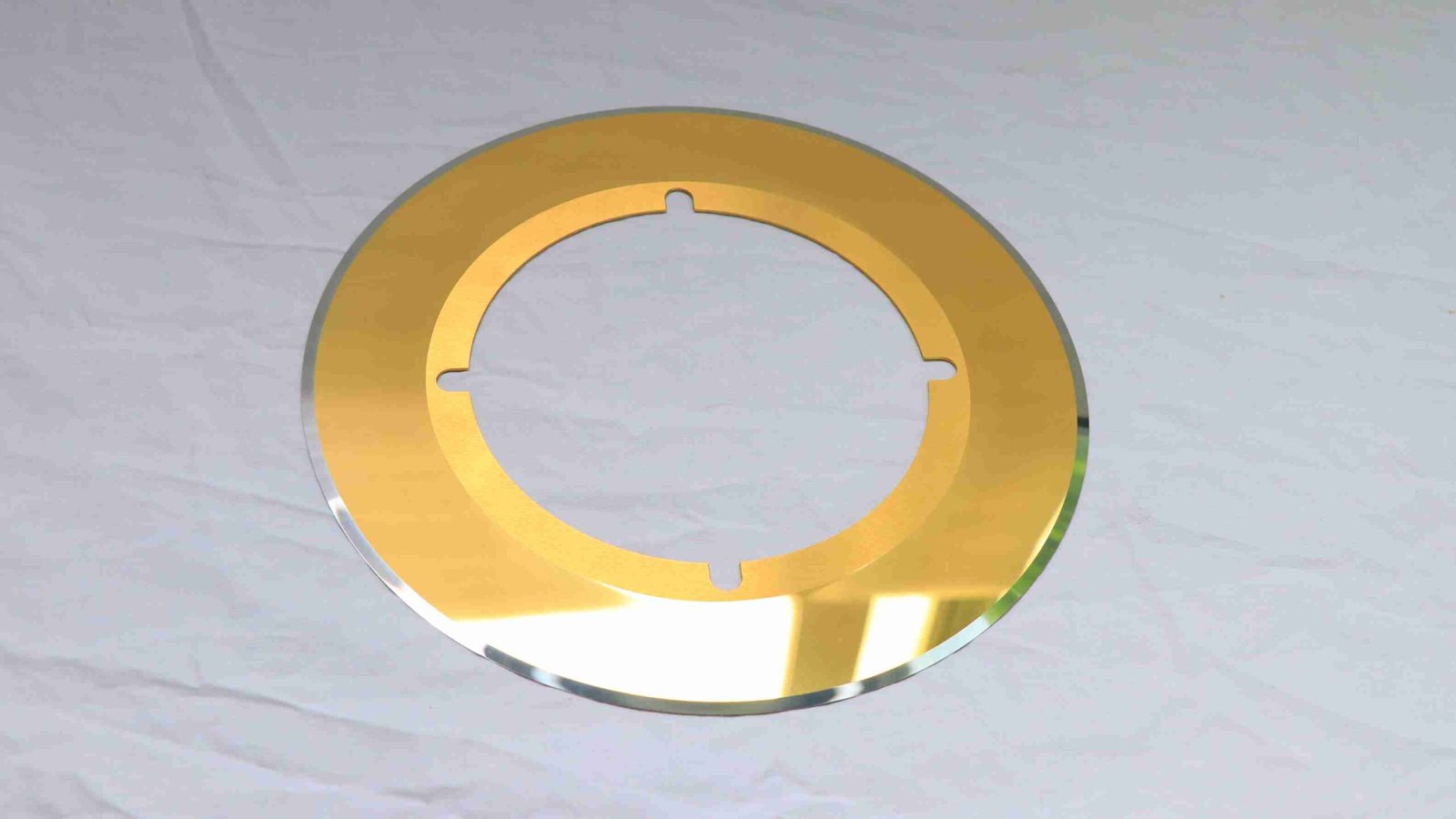

- Increased Hardness: Coatings like Titanium Nitride (TiN, a gold color) or Titanium Aluminum Nitride (TiAlN, a dark violet color) are significantly harder than the blade material itself. This ultra-hard layer protects the cutting edge from abrasive wear, making it last much longer.

- Reduced Friction: These coatings are also extremely smooth, which lowers the coefficient of friction. This means the blade glides through material more easily. Less friction means less heat buildup, which is a major cause of edge degradation. For materials like plastic films or adhesives, this also prevents them from melting and sticking to the blade.

- Corrosion Resistance: The coating acts as a barrier, protecting the blade from rust or chemical reactions, which is essential in food processing or medical applications.

The Cost of Customization and Small Batches

Most blade manufacturers are set up for mass production of standard sizes. This is the most cost-effective way to operate.

- Tooling & Setup: When a customer needs a blade with a unique angle, a special set of holes, or a non-standard length, we have to create new molds or tooling. Our CNC machines must be reprogrammed and calibrated for the new design. This setup process takes time and expertise.

- Economies of Scale: For a large production run of 1,000 blades, these setup costs are spread out, so the cost per blade is low. For a custom order of just 10 or 20 blades, that same setup cost is divided among a much smaller number, so the price per unit is naturally higher.

While a custom blade costs more upfront, it's often the only way to solve a specific cutting challenge. Using the "wrong" standard blade can be far more expensive in the long run due to material waste and lost productivity.

Is Heavier Weight Indicative Of Higher Quality For Tungsten Carbide Blades?

Many buyers assume a heavier blade must be better, right? This is a dangerous oversimplification that can lead you to buy the wrong blade. A blade's weight tells you about its composition, not its quality.

No, a heavier weight does not mean higher quality. Weight is determined by the blade's alloy grade—specifically, its density and cobalt content4. The "best" blade has the right grade for your application, which could be heavier or lighter depending on the required hardness and toughness.

This is one of the most common myths I have to correct. A customer will call and say, "I have a blade from another supplier, and it's heavier than yours. Why is yours more expensive?" It's a fair question, but it's based on a flawed assumption. Weight is simply a physical property, not a measure of performance. The critical factor is the blade's grade, which dictates its behavior. It’s like comparing two cars based on their weight. A heavy luxury sedan isn't "better" than a lightweight sports car; they are just built for different purposes. The same is true for blades.

Understanding Material Grades And Density

Tungsten carbide is not a pure metal; it's a composite material, an alloy. It's made of hard tungsten carbide particles held together by a softer, tougher metallic binder, which is usually cobalt. The percentage of cobalt determines the grade of the alloy.

- Low Cobalt Grades (e.g., YG6, 6% Cobalt): These grades are extremely hard and wear-resistant. Since tungsten carbide is much denser than cobalt, these blades are heavier. They are perfect for cutting abrasive materials where holding a sharp edge is key.

- High Cobalt Grades (e.g., YG12, 12% Cobalt): Adding more cobalt binder makes the alloy tougher and more resistant to impact. It's less likely to chip or crack if it hits a hard spot. However, since cobalt is less dense than tungsten carbide, these tougher blades are actually lighter than their harder counterparts of the same size.

So, a heavier blade is likely a harder grade with less cobalt, while a lighter blade is a tougher grade with more cobalt. Neither is universally "better."

Matching The Grade To The Application

The most important decision is choosing the grade that matches your cutting needs.

- Cutting Paper or Fiberglass? These are highly abrasive. You need a very hard, wear-resistant blade. A low-cobalt, heavier grade like YG6 or YG8 would be the best choice.

- Cutting Metal or Wood with Nails? These applications involve impact and shock. You need a tough blade that won't shatter. A high-cobalt, lighter grade like YG12 or YG15 would be more suitable because it can absorb the shock without fracturing.

Judging a blade by its weight is a shortcut that leads to the wrong destination. Instead of asking "How heavy is it?", the right question is "What grade is it, and is that the right grade for my job?". That is where our expertise at PASSION comes in. We help you choose the right composition for optimal performance, regardless of its weight.

Conclusion

Blade prices reflect real differences in materials, manufacturing, and precision. A cheaper blade is not a bargain

Learn about the potential issues with recycled powder that can affect blade quality. ↩

Learn about this advanced technique that enhances blade density and performance. ↩

Explore how sintering contributes to the durability and strength of blades. ↩

Learn about the role of cobalt in determining blade toughness and durability. ↩