Your blades are failing too soon, and you think it's just wear and tear. But a hidden enemy, chemical reaction, is likely costing you money, time, and production quality.

A blade's chemical properties1 determine its resistance to rust, heat, and chemical attack. This stability directly impacts its sharpness, cutting precision, and overall lifespan, especially in humid, high-temperature, or chemical-rich environments. Choosing the right material chemistry prevents premature failure and reduces maintenance costs.

When I talk to my clients, they often focus on mechanical properties like hardness and toughness. These are absolutely critical, and we spend a lot of time perfecting them. But these features are only half of the story. The invisible world of chemistry plays an equally important role in determining whether a blade succeeds or fails. The way a blade's material reacts—or doesn't react—with its environment is key to its performance. Let's explore why the chemical side of your blade matters just as much.

How Does A Blade's Material Recipe Affect Its Chemical Defense?

Ever wonder why two blades with similar hardness perform so differently? It's frustrating when one blade lasts for months while another fails in weeks. The secret is in the recipe.

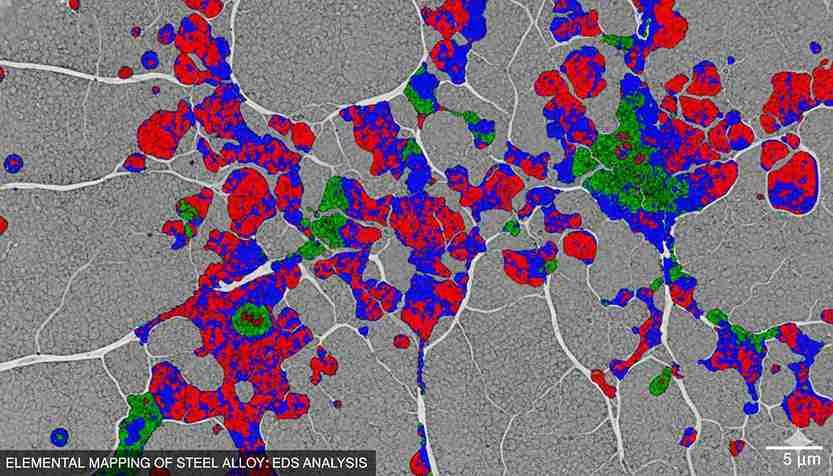

A blade’s material recipe, or its chemical composition, dictates its core strengths. Elements like chromium provide corrosion resistance2, tungsten and molybdenum offer heat stability, and cobalt adds toughness. This unique blend determines if a blade will survive its specific cutting environment, making it the foundation of performance.

The final product is only as good as its ingredients. The choice of blade material is the first and most critical step, and it all comes down to chemistry. The mix of elements in the steel or carbide determines its inherent ability to stand up to chemical challenges. It's not just about being hard; it's about being chemically resilient. I’ve seen countless cases where a super-hard blade failed quickly simply because its chemical makeup wasn't right for the job.

Key Elements And Their Roles

Think of steel as a base recipe that we enhance with different "spices" or alloying elements. Each element adds a unique property that contributes to the blade's chemical defense. For example, carbon is essential for hardness, but too much can make the blade brittle and more prone to fracture. Chromium is the hero of corrosion resistance; it forms an invisible, protective "skin" on the blade's surface. Molybdenum and tungsten are crucial for blades that work in high heat, as they help the steel keep its strength and structure when temperatures rise.

Comparing Common Blade Materials

The choice of base material is just as important. Different materials have fundamentally different chemical structures, which dictate how they behave.

| Material Type | Key Chemical Properties | Best For... |

|---|---|---|

| Carbon Steel | High hardness due to carbon. Prone to rust without protective coating. | Dry cutting applications where cost is a major factor. |

| Stainless Steel | Contains >10.5% Chromium. Excellent corrosion resistance. | Humid or wet environments like food processing, medical. |

| High-Speed Steel (HSS) | Rich in Tungsten, Molybdenum. Retains hardness at high temperatures. | High-speed cutting where friction generates a lot of heat. |

| Tungsten Carbide | Extremely hard and chemically inert. Excellent corrosion and wear resistance. | Abrasive materials, chemical fibers, adhesives. |

| Ceramic | Chemically inert to almost everything. Non-metallic. No rust. | Cutting chemically aggressive materials like film and fiber. |

Choosing the right material isn't just a technical decision; it's a business decision. The right chemical makeup leads to longer blade life, less downtime, and better product quality.

Why Is Resisting Corrosion And Oxidation Crucial For Blade Longevity?

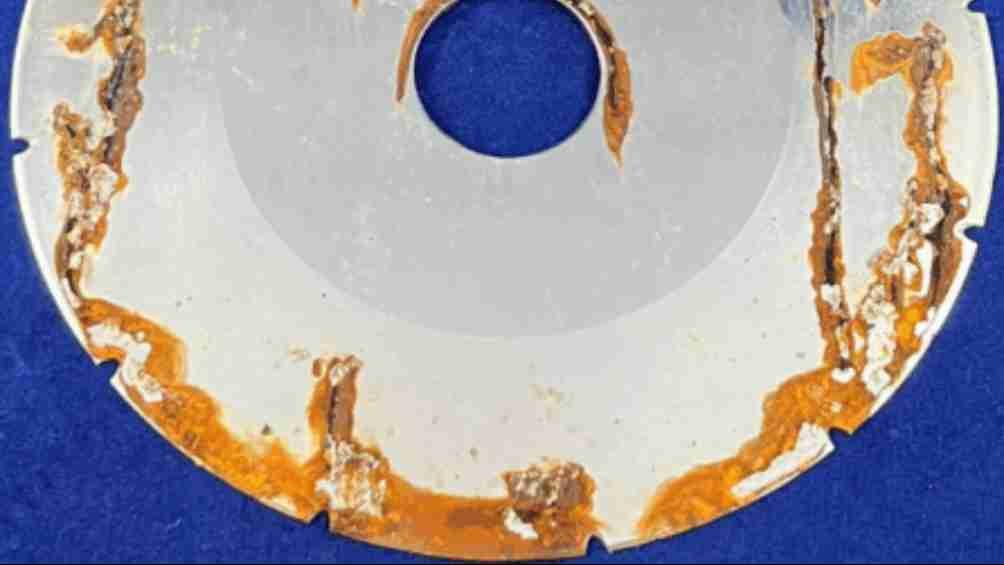

Seeing rust on a new blade or a heat-blackened edge is disheartening. This damage isn't just cosmetic; it ruins the cutting edge and forces you to halt your production line.

Corrosion (rust) from moisture and oxidation from heat directly attack a blade's sharp edge. Resistance to these chemical attacks is vital because it preserves the blade's integrity, maintains cutting precision, and significantly extends its useful life, especially in food processing or high-speed cutting applications.

I think of corrosion and oxidation as two of the biggest enemies of a sharp edge. They don't wear the blade down through friction; they destroy it at a chemical level. One is a slow, silent process, and the other happens in the heat of the moment, but both can bring your operations to a grinding halt. That’s why a blade’s ability to defend against these two forces is a non-negotiable feature for so many of the industries I work with. A blade that can't resist these attacks will never deliver the performance or lifespan you need.

The Fight Against Rust (Corrosion)

Corrosion is essentially the process of metal, like iron in steel, trying to return to its natural state, which is ore. Moisture and oxygen are the main culprits. For industries like food processing, pharmaceuticals, or even plastic film cutting in humid climates, this is a huge problem. A rusty blade is not only unhygienic but also dull. The rust creates a rough, pitted surface that drags and tears material instead of slicing it cleanly.

This is where stainless steel shines. As I mentioned, the chromium in stainless steel (like the 420 or 440C grades we often recommend) reacts with oxygen in the air to form a very thin, stable, and invisible layer called a passive film. This film seals the surface and protects the iron in the steel from coming into contact with moisture, effectively stopping rust before it starts. I remember a client in the seafood industry who was replacing carbon steel blades every few days due to saltwater corrosion. We switched them to a high-chromium stainless steel blade, and their blade lifespan jumped to several weeks, which completely changed their maintenance schedule.

Handling The Heat (Oxidation)

Oxidation is a similar chemical process but supercharged by heat. When a blade gets very hot during high-speed cutting, the metal on the surface can react rapidly with oxygen. This can form a brittle oxide layer, often seen as a blue or black discoloration. This layer weakens the cutting edge, leading to chipping and rapid dulling, a phenomenon sometimes called "edge annealing."

For applications like hot-cutting plastic or high-speed metal slitting, oxidation resistance3 is paramount. This is where materials like High-Speed Steel (HSS) and tungsten carbide excel. The tungsten, molybdenum, and cobalt in HSS help it maintain its hardness and structure at high temperatures. In tungsten carbide, elements like titanium and aluminum are sometimes added to form extremely stable oxide layers (like Al₂O₃) at high temperatures. This layer acts as a thermal barrier, protecting the material underneath and allowing the blade to keep cutting effectively even when it's glowing hot.

What Makes A Blade Chemically Stable In Harsh Industrial Environments?

Are your blades failing even when cutting soft materials? The problem might not be wear but the chemicals in your process, silently eating away at the blade’s edge and causing unpredictable failure.

Chemical stability is a blade's ability to remain unchanged when in contact with acids, solvents, or adhesives. Materials like ceramic and tungsten carbide are highly inert, preventing chemical reactions that can dull or corrode the edge. This is essential for industries like film, fiber, and electronics.

Beyond just water and heat, many industrial processes involve a whole range of other chemicals. Think about the adhesives on tape, the solvents used in printing, or the acidic nature of some food products. If a blade material is reactive, it will be attacked by these substances. This type of chemical wear is often overlooked because it's not as obvious as a chipped edge, but it can be just as destructive. A chemically stable blade is one that simply doesn't react. It remains neutral and unchanged, which is exactly what you need for consistent, reliable cutting.

The Inert Advantage

The most chemically stable materials are often those that are the most "boring" from a reactive standpoint. Tungsten carbide and ceramics are champions here. They are compounds that are already in a very stable state, so they have very little desire to react with anything else. This makes them perfect for industries where the material being cut is chemically aggressive. For example, in the manufacturing of synthetic fibers, blades are exposed to various chemical monomers and solvents. A standard steel blade might corrode or pit in this environment, but a ceramic or tungsten carbide blade will perform flawlessly for a much longer time. It’s this inertness that makes them so valuable. It ensures that the only thing affecting the blade is the physical act of cutting, not a side-battle with chemistry.

Protecting The Foundation: Decarburization Resistance

Chemical stability also starts from within—specifically, how the blade is made. During the heat treatment process, which is essential for hardening steel, there is a risk of a damaging chemical reaction called decarburization. If the furnace atmosphere isn't perfectly controlled, the carbon near the surface of the steel can react with oxygen and literally burn away. This leaves a soft, low-carbon layer on the surface of the blade. It's like having a suit of armor with a soft, weak outer layer. This decarburized surface will wear down incredibly fast and is more susceptible to chemical attack.

We prevent this by using advanced techniques like vacuum heat treatment. By removing the oxygen from the furnace, there is nothing for the carbon to react with. This ensures the blade's surface retains its full carbon content, full hardness, and full chemical integrity. High-alloy materials like HSS and some high-chrome steels also have better natural resistance to decarburization. Ensuring a blade is free from this defect is a critical, and often invisible, quality step that has a massive impact on its final performance and lifespan.

A Real-World Example: Solving A Sticky Problem

I love it when we can solve a customer's problem with a simple material change. I recently worked with a company in Italy. They manufacture high-tack industrial tapes, and their production line was suffering.

They were using standard high-speed steel (HSS) blades to slit large rolls of adhesive-coated film. The problem was the aggressive adhesive. The chemicals in the glue were reacting with the surface of the HSS blades. This caused two things to happen: the blade's edge would dull very quickly from the chemical wear, and the sticky residue would bond more strongly to the reactive steel surface. They were having to stop the line every two hours to clean or replace the blades. It was a nightmare for their efficiency.

After discussing their process, I knew the HSS material was the root cause. It just wasn't chemically stable enough for the adhesive. I recommended they switch to one of our solid tungsten carbide blades. Tungsten carbide is extremely inert and has virtually no chemical reaction with their adhesive. To make it even better, we added a polished, non-stick surface finish.

The results were immediate. The new carbide blades showed no chemical wear, and the adhesive residue no longer bonded to the blade surface. Their blade change interval went from just 2 hours to over 24 hours of continuous operation. This single change dramatically reduced their downtime, improved their cut quality, and saved them a lot of money in the long run. It was a perfect example of how choosing a blade for its chemical properties can solve a problem that hardness alone never could.

Conclusion

A blade's physical hardness is just one part of the story. Its chemical properties—resistance to corrosion, heat, and chemicals—are what truly guarantee its performance and long life in your specific application.