Struggling with rising tungsten carbide blade costs? These price hikes disrupt your budget and eat into your profits, leaving you searching for answers. Let's uncover the real reasons why.

Prices have surged due to a combination of factors. The key raw material, tungsten powder1, has become more expensive due to tight supply and soaring demand from sectors like new energy and high-end manufacturing. This, plus rising production costs, is pushing prices up.

The story behind the price increase is complex, involving global supply chains, economic shifts, and new technologies. I see these impacts firsthand when talking to my customers and partners every day. Understanding these moving parts is crucial for anyone who relies on these essential tools. But what does this really mean for your day-to-day operations and your bottom line? Let's break it down further so you can make informed decisions for your business.

What Are The Core Reasons Behind The Raw Material Price Spike?

Confused by why raw material costs are suddenly so high? This uncertainty makes planning difficult and threatens your material budget. Let’s look at the main supply and demand factors.

The price spike is driven by a two-sided pressure. On one hand, major tungsten producers are limiting supply. On the other hand, booming industries like new energy, military, and advanced manufacturing are creating a massive increase in demand, creating a classic supply-demand imbalance.

China is the world's largest producer of tungsten, and any shift there affects the global market. Right now, resource suppliers are not releasing large quantities of tungsten powder into the market, which creates a supply squeeze. At the same time, global demand is growing fast.

Supply-Side Squeeze

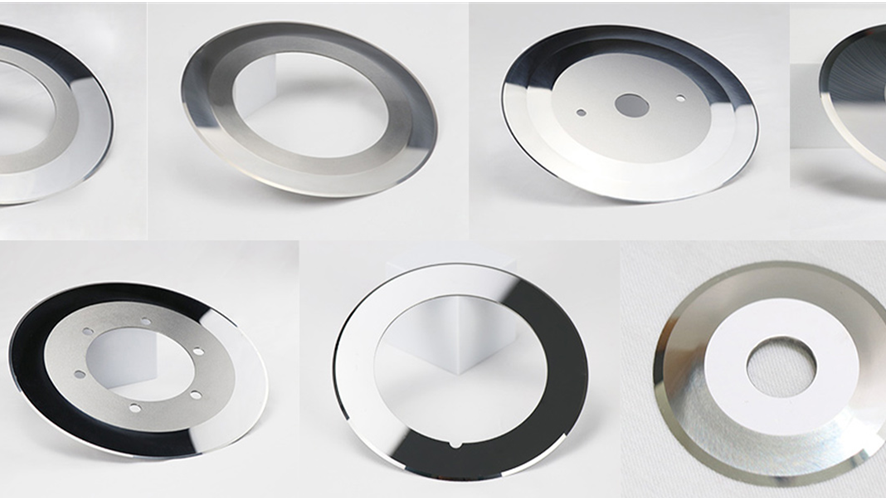

The primary raw material for our tungsten carbide blades is tungsten powder. Suppliers are holding back resources, creating scarcity in the market. This isn't just a simple business decision. It is tied to long-term resource management strategies and market forecasts. When the supply is intentionally kept tight, the price for the available material naturally goes up.

Demand-Side Surge

The demand for tungsten isn't just increasing; it's exploding in specific high-growth sectors.

| Supply Factors | Demand Factors |

|---|---|

| Limited release of tungsten resources | Growth in the new energy sector (e.g., wind turbines) |

| Strategic resource management | Increased use in military and aerospace |

| Rising extraction costs | Expansion of high-end, precision manufacturing |

This combination of tight supply and booming demand creates a powerful upward pressure on prices, which is then passed down to the final cost of the blades.

What Is The Impact Of Rising Tungsten Carbide Blade Prices On End Users?

Worried about how rising blade prices will affect your business? Higher costs can shrink your margins quickly. Here’s how you can prepare for the direct and indirect impacts.

End users face direct cost increases for consumable blades, which disrupts purchasing budgets. It also creates a risk where some suppliers may offer cheap, low-quality alternatives that can cause more damage and long-term costs. It is crucial to stay vigilant.

The price of a single blade might seem small, but when you use hundreds or thousands a month, the numbers add up very quickly. This isn't just an inconvenience; it affects your entire financial planning.

Direct Hit To Your Operational Costs

For any business in machining, woodworking, or manufacturing, blades are a key consumable. A price hike directly translates into higher operating costs. For example, a CNC machining workshop that uses 200 tungsten carbide inserts per month would see its costs climb significantly. A 20% price increase could mean thousands of dollars in extra expenses each year, money that could have been invested elsewhere. This forces procurement managers to go back to the drawing board and rework their budgets, often leading to tough decisions.

The Hidden Danger: Beware Of "Too Good To Be True" Deals

When prices are high, it’s tempting to look for bargains. But this is exactly when you need to be most careful. I recently spoke with a new client, from a German automotive parts company. He was lured by a supplier offering blades at 30% below the market rate. The deal seemed too good to pass up. Unfortunately, the blades were made from inferior materials. They wore out twice as fast and even caused damage to an expensive workpiece. The money he thought he was saving was lost many times over in replacement costs and production delays. This story is a strong reminder that in times of market volatility, product quality and supplier reliability are more important than ever. Sacrificing quality for a lower price is a trap that often leads to greater losses.

How Can Buyers Develop Smart Coping Strategies?

Feeling powerless against rising prices? Simply cutting costs isn't the answer and might hurt quality. Let’s explore smarter strategies to get more value and control your spending.

Smart buyers should focus on Total Cost of Ownership (TCO)2 instead of just the unit price. Building long-term relationships with reliable suppliers, planning purchases in advance, and optimizing blade use through proper maintenance and regrinding services3 are key strategies.

Navigating a high-price market is challenging, but it's also an opportunity to adopt smarter purchasing habits. Instead of reacting to prices, you can proactively manage your costs and improve efficiency. It's about shifting your mindset from chasing the lowest price to securing the best long-term value.

Shift From Price-Based To Value-Based Purchasing

The smartest approach right now is to look at the "Total Cost of Ownership" (TCO). A blade that costs 20% more but lasts 50% longer is actually cheaper in the long run. It reduces downtime for blade changes, lowers overall consumption, and ensures consistent quality. This is the perfect time to switch from "price-based buying" to "value-based buying."

The Power Of A Reliable Partner

In an unstable market, a good supplier is worth more than gold. A reliable partner like PASSION doesn’t just sell you a product. We work with you to understand your needs. We provide stable pricing where possible, offer expert advice, and ensure you get consistent quality. Building a long-term relationship means we can help you plan your inventory, anticipate market changes, and even develop custom solutions to improve your efficiency. This partnership approach turns a simple transaction into a strategic advantage.

Optimize And Extend Blade Lifespan

You can also find significant savings by getting the most out of every blade you buy. Proper use and regular maintenance are critical. For some types of blades, professional regrinding services can restore them to near-new performance for a fraction of the cost of a replacement. We often advise our clients on best practices for blade care and whether regrinding is a viable option for them. It’s an effective way to lower costs without compromising on cutting quality.

Conclusion

Rising tungsten carbide blade prices are a challenge. But with the right knowledge and a focus on long-term value over short-term costs, you can navigate this market successfully.

Exploring the reasons behind the rising costs of tungsten powder can provide insights into market dynamics affecting your business. ↩

Learning about TCO can help you make smarter purchasing decisions that prioritize long-term value over short-term savings. ↩

Exploring regrinding services can reveal cost-saving opportunities that maintain quality without the need for new purchases. ↩