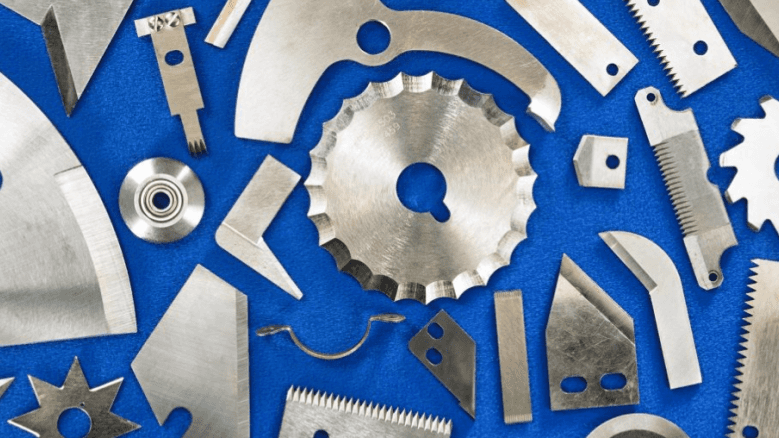

Are dull blades and constant replacements hurting your production line? The problem isn't just the blade, but its material. Tool steel provides the durability and precision you need.

Tool steel is essential because it offers a superior combination of high hardness1, wear resistance2, and toughness3. This unique balance ensures blades stay sharp longer, resist chipping, and perform reliably under intense industrial cutting pressures, making it the ideal choice for most applications.

I've seen countless operations struggle with subpar blades. They often think it's a machine issue or an operator error. But almost every time, the root cause is the blade material. Understanding why tool steel4 is so dominant can completely change how you approach your cutting process. Let's explore what makes this material so special and how it can benefit your work.

What Is Tool Steel?

You hear the term "tool steel" constantly but are not sure what it is. This uncertainty can lead to costly mistakes. Let's break down this fundamental material simply.

Tool steel is a special category of carbon and alloy steels. It is specifically designed for making tools, like industrial blades. Special alloying elements and heat treatment5s give it high hardness, wear resistance, and toughness, making it perfect for shaping other materials through cutting.

Tool steel isn't just one material. It's a family of steels engineered for specific tasks. The magic happens through two key processes: alloying and heat treatment.

Key Components And Processes

Alloying involves adding elements like chromium, vanadium, and molybdenum to the iron and carbon base. These elements create unique properties. For example, chromium increases hardness and corrosion resistance. Vanadium improves wear resistance by forming hard carbides. Then, a precise heat treatment carefully heats and cools the steel. This process refines the steel's internal structure, or microstructure. This locks in the desired hardness and toughness for the final blade.

A paper mill client in Brazil was a perfect example. They used basic steel blades that dulled fast, creating paper dust and rough edges. After I introduced them to our D2 tool steel blades, their blade life6 tripled, and cut quality improved dramatically. It's all about the right material science.

What Are The Key Performance Characteristics Of Tool Steel?

You know tool steel is better, but what makes it so special for blades? Without understanding its core strengths, you might choose the wrong type. Let’s explore the key characteristics.

The key characteristics are high hardness to maintain a sharp edge, excellent wear resistance to last longer, and good toughness to prevent chipping or breaking under impact. It also boasts great dimensional stability during heat treatment, ensuring the blade keeps its precise shape.

The real advantage of tool steel is the balance of its properties. You cannot just have extreme hardness. A blade that is too hard might be brittle and shatter. True performance comes from optimizing these characteristics for the job.

The Performance Triangle

Think of it as a triangle: Hardness, Toughness, and Wear Resistance. You often have to trade a little of one characteristic to get more of another. The goal is to find the perfect blend for your specific application.

| Characteristic | What It Means For Your Blade | Why It Matters |

|---|---|---|

| Hardness | Resists deforming and keeps a sharp edge. | Longer cutting life, cleaner cuts. |

| Toughness | Resists chipping and breaking from impact. | Safety, reliability, less downtime. |

| Wear Resistance | Resists friction and abrasion damage. | Extended performance in harsh conditions. |

I remember working with a packaging converter in Poland. They used very hard blades that kept breaking when cutting tough plastic films. We switched them to a modified tool steel with slightly less hardness but significantly more toughness. Their blade breakages stopped completely.

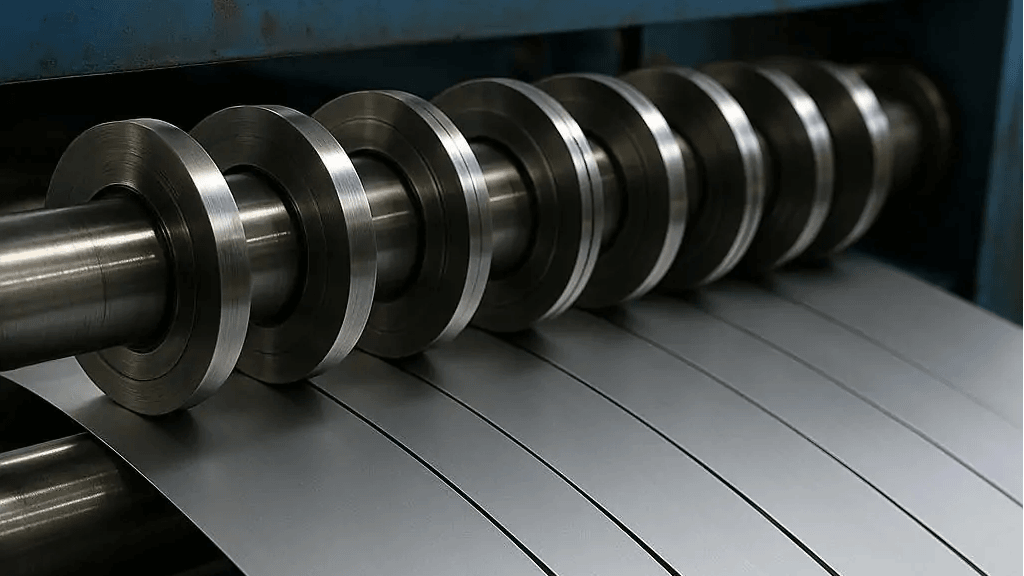

Common Types Of Tool Steel And Their Application Industries

The term "tool steel" covers many different materials. Using the wrong one can lead to poor performance and blade failure. Let’s review the main types and their uses.

The main types include cold-work tool steels (like D27) for paper and film; hot-work tool steels (like H138) for high-temperature cutting; and high-speed steels9 (like M210) for high-speed metalworking. Each is designed for specific temperatures, speeds, and materials.

Not all tool steels are created equal. They are grouped into categories based on their intended working conditions, especially temperature. Understanding these groups is the first step to making an informed choice for your industry.

The Main Categories

Let's look at the three most common families of tool steel we work with at PASSION. Each one has a distinct purpose.

| Tool Steel Type | Key Feature | Common Industries |

|---|---|---|

| Cold-Work | High wear resistance at room temp. | Paper, Plastics, Textiles |

| Hot-Work | Maintains hardness at high temps. | Metal Forging, Die Casting |

| High-Speed (HSS) | Keeps a hard edge at high speed & heat. | Metal Cutting, Woodworking |

I once helped a textile company in Turkey. They were using expensive High-Speed Steel blades to cut synthetic fabrics. While effective, it was unnecessary. The process did not generate extreme heat. We switched them to a high-chromium D2 cold-work steel. It provided the wear resistance they needed at a much better price, saving them thousands annually.

How To Select The Appropriate Tool Steel Blade?

With so many tool steel options available, choosing the right one feels complex. A poor choice can waste money and stop production. Let's simplify the selection process for you.

To select the right tool steel, analyze four key factors: the material you are cutting, your machine's operating speed, the working temperature, and your required tool life. Matching the steel's properties to these demands ensures optimal performance, efficiency, and cost-effectiveness for your operation.

Selecting the right tool steel blade isn't about finding the "best" steel. It is about finding the right steel for your specific job. To do that, I always ask my clients to consider four critical questions.

A 4-Step Checklist For Blade Selection

- What are you cutting? The hardness and abrasiveness of the material is the most important factor.

- How fast are you cutting? Higher speeds generate more heat and require steels that can handle it, like HSS.

- What is the temperature? Is it a cold or hot application? This determines if you need a cold-work or hot-work steel.

- How long do you need the blade to last? Your expectations for tool life and your budget will guide the final choice between different grades.

A food processor in Mexico faced a challenge cutting frozen food blocks. The blades needed to be tough to handle impact. They also needed to be highly wear-resistant against the abrasive ice. After reviewing their process, we chose a blade made from powder metallurgy steel. This gave them the perfect balance of toughness and longevity.

Conclusion

In summary, tool steel is the foundation of reliable industrial cutting. Choosing the correct type based on your specific application is key to maximizing efficiency, quality, and profitability.

Learn why high hardness is crucial for tool steel and how it affects blade longevity and performance. ↩

Discover the significance of wear resistance in industrial blades and its role in reducing replacement costs. ↩

Understand the importance of toughness in tool steel and how it prevents blade chipping and breaking. ↩

Explore the advantages of tool steel for industrial applications and how it enhances blade performance. ↩

Explore the heat treatment process and its significance in achieving desired properties in tool steel. ↩

Explore strategies to extend blade life and improve efficiency in industrial cutting processes. ↩

Explore this link to understand how D2 tool steel enhances blade performance and longevity in various industries. ↩

Explore this link to understand H13's unique properties and its ideal applications in high-temperature cutting, enhancing your production efficiency. ↩

Discover the advantages of high-speed steels in metalworking and their performance at high speeds. ↩

Explore this link to understand M2's unique properties and its ideal applications in high-speed metalworking. ↩