Struggling with frequent blade changes1 and poor cutting quality? This production inefficiency costs you time and money. Tungsten carbide blades offer a durable, high-performance solution for modern manufacturing challenges.

Tungsten carbide blades are popular because their extreme hardness and wear resistance mean they last much longer than traditional steel blades. This significantly reduces downtime, boosts production efficiency, and delivers cleaner cuts, ultimately leading to better long-term cost-effectiveness across many demanding industries.

The benefits sound impressive, but what does this mean for your bottom line and daily operations? The simple material switch can completely transform a company's production floor. It’s not just about a better blade; it's about a smarter way of working. Let's break down the real-world impact of switching to tungsten carbide and see how it solves common production headaches.

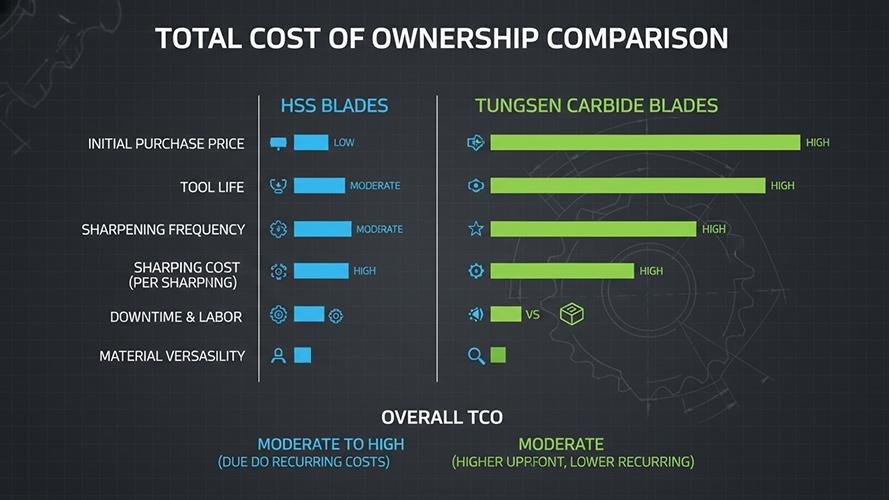

Are Tungsten Carbide Blades Really Cost-Effective Despite Being So Much More Expensive Than High-Speed Steel Blades? How Do You Calculate The Return On Investment?

Worried about the high initial cost of tungsten carbide blades? You might think they're too expensive. But understanding their true return on investment reveals significant long-term savings.

Yes, they are highly cost-effective. You can calculate the Return on Investment (ROI) by looking at the Total Cost of Ownership (TCO). Factor in the blade's longer life, reduced downtime for changes, and lower scrap rates against the costs of cheaper steel blades. The savings add up quickly.

The initial price tag is what everyone sees first. But in my experience, the most successful companies look beyond that. They focus on the Total Cost of Ownership (TCO). This includes not just the purchase price, but also the costs of downtime, labor for blade changes, wasted material from dull cuts, and frequent reordering. I recently worked with a packaging client in Germany who was hesitant for this very reason. They were using high-speed steel (HSS) blades and changing them twice per shift. After we switched them to our tungsten carbide blades, they only needed to change them once every few weeks. The math spoke for itself. Their initial investment was higher, but the ROI was realized in less than three months through massive savings in labor and radically increased machine uptime.

How To Calculate Your TCO

Think about it this way. You are not just buying a blade; you are buying uptime and quality.

| Cost Factor | High-Speed Steel (HSS) Blade | Tungsten Carbide (TC) Blade |

|---|---|---|

| Initial Cost | Low | High |

| Lifespan | Short (e.g., 1 Day) | Very Long (e.g., 20+ Days) |

| Blade Changes | Frequent | Infrequent |

| Downtime Cost | High | Very Low |

| Labor Cost | High | Very Low |

| Scrap Rate | Higher (due to dulling) | Lower (maintains sharpness) |

| Total Cost | High Long-Term Cost | Low Long-Term Cost |

If Production Efficiency Isn't Improving And Downtime For Blade Changes Is Too Frequent, Isn't It Time To Upgrade Your Blades?

Is your production line constantly halted for blade changes? This frustrating downtime hurts your output and profits. Upgrading your blades is a direct path to higher efficiency.

Absolutely. Frequent blade changes are a major bottleneck. Upgrading to tungsten carbide blades, which can last 10 to 20 times longer than steel, directly tackles this problem. This switch boosts machine uptime, increases output, and reduces labor costs for maintenance.

Downtime is a silent killer of profitability. It's not just the 15 minutes it takes an operator to swap a blade. It's the time the machine takes to ramp down and ramp back up. It’s the material that gets wasted during the first few cuts for quality checks. It's the cumulative effect on your entire production schedule. I remember a case with a large textile manufacturer in Vietnam that was cutting abrasive synthetic fabrics. Their HSS blades were becoming dull within a single eight-hour shift. The operators were spending more time changing blades than focusing on quality control. After we supplied them with our tungsten carbide blades, their blade-change interval went from once a day to once a month. The production manager told me it completely changed their workflow, eliminated a major source of frustration, and allowed them to exceed their production targets for the first time.

The Hidden Costs Of Frequent Downtime

A simple upgrade has a powerful ripple effect on your entire operation. It empowers your team to focus on production, not just maintenance.

| Metric | Before Upgrade (HSS) | After Upgrade (TC) |

|---|---|---|

| Blade Changes | Daily | Monthly |

| Daily Downtime | ~45 minutes | ~1 minute (amortized) |

| Operator Focus | Machine Maintenance | Production & Quality |

| Output | Inconsistent | Consistently High |

| Team Morale | Low (frustrated) | High (empowered) |

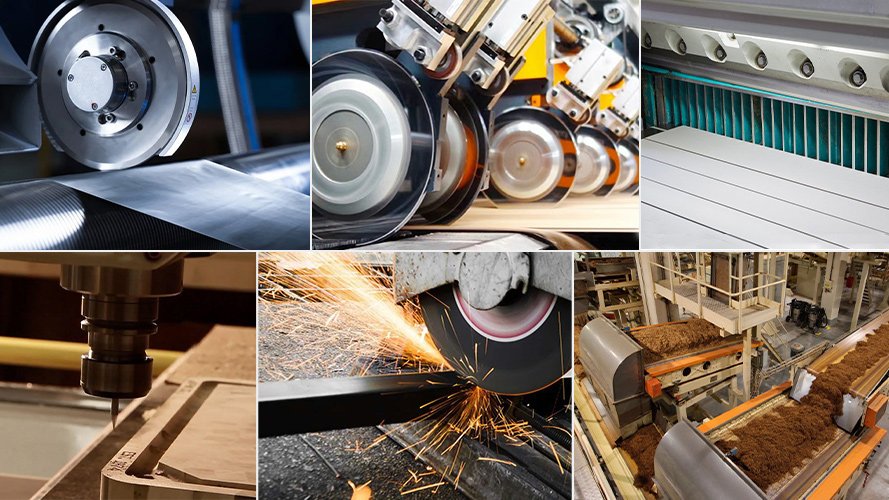

Can Tungsten Carbide Blades Handle High-Speed Automation And Cut Difficult Materials?

Do your blades fail when cutting tough materials or running on high-speed machines? This causes defects and waste. Tungsten carbide blades are designed for these exact, demanding modern challenges.

Yes, perfectly. Tungsten carbide's high hardness and heat resistance make it ideal for high-speed automated cutting. It maintains a sharp edge when processing abrasive materials like composites, fiberglass, and dense plastics, ensuring consistent precision and minimizing defects.

Modern manufacturing is all about speed and precision. As companies integrate more automation, the demands on every component increase, especially the cutting blade. A blade that can't handle the speed or the material becomes the weakest link. Tungsten carbide shines here. Its material properties2, specifically its incredible hardness and ability to resist heat buildup, allow it to maintain a sharp, stable cutting edge even under intense conditions. I worked with a plastics recycling company in Mexico facing this issue. They were processing baled plastic film that was often contaminated with abrasive dirt and grit. Their standard steel blades wore out in a matter of hours, causing machine jams and producing poor-quality recycled pellets. By switching to tungsten carbide blades, they could run their lines continuously for several days, cutting through the abrasive material without a drop in performance.

Why Material Properties Matter

The right blade material ensures your automated systems can perform at their full potential, without being held back by a weak link.

| Blade Property | Challenge | Why Tungsten Carbide Succeeds |

|---|---|---|

| Extreme Hardness | Abrasive Materials | Resists wear from materials like fiberglass, carbon fiber, and contaminated plastics. |

| Heat Resistance | High-Speed Cutting | Stays hard and sharp, preventing deformation and quality loss at high RPMs. |

| Stiffness | High-Precision Cuts | Minimizes blade vibration and deflection, ensuring consistent, tight-tolerance cuts. |

Is Tungsten Carbide Only For Specialized Industries, Or Can It Benefit My Specific Application?

Think tungsten carbide is only for heavy metal-cutting? You might believe it’s not right for your industry. But its benefits are surprisingly versatile, touching nearly every manufacturing sector.

Tungsten carbide benefits a vast range of industries. Its superior wear resistance and clean-cutting ability are valuable in paper, packaging3, textiles, plastics, rubber, and even food processing. If your process requires sharp, durable blades, tungsten carbide is likely a great fit.

It's a common misconception that tungsten carbide is only for cutting metal or other extremely hard materials. In reality, any industry that values reduced downtime and a clean cut can benefit. I’ve helped clients in the paper industry reduce dust creation, clients in textile manufacturing4 cut tough fabrics without fraying, and clients in packaging achieve perfect seals with cleaner cuts. A memorable case was a food processing5 plant in the USA that was cutting large, frozen blocks of vegetables. Their stainless steel blades dulled quickly, requiring frequent sharpening and creating a risk of metal fragments. Switching to our food-grade tungsten carbide blades not only extended the blade life by over 30 times but also provided a cleaner, safer cut that improved their product quality and food safety compliance.

A Look Across Industries

From food to film, the core benefits of longevity and precision are universal. Tungsten carbide's value is not limited to a niche.

| Industry | Common Challenge | How Tungsten Carbide Helps |

|---|---|---|

| Paper & Corrugated | Blade dulling from paper dust, causing rough edges. | Stays sharp longer, reduces dust, provides cleaner slits and scores. |

| Plastics & Film | Abrasive materials and additives wearing down blades quickly. | Excellent wear resistance leads to less downtime and reduced "angel hair" plastic strands. |

| Food Processing | Frequent cleaning and sharpening, risk of contamination. | High corrosion resistance, holds an edge longer for cleaner, safer cuts. |

| Textiles & Fabrics | Fraying and pulling of delicate or abrasive materials. | Maintains a razor-sharp edge for clean, precise cuts without damaging the material. |

Conclusion

Upgrading to tungsten carbide blades is a strategic investment in efficiency and quality. It reduces downtime, lowers long-term costs, and boosts performance, proving its value across diverse industrial applications6.

Learn the best practices for scheduling blade changes to maximize efficiency. ↩

Understand how the properties of materials influence the performance of manufacturing tools. ↩

Explore ways to enhance packaging efficiency and reduce costs. ↩

Understand the common challenges in textile manufacturing and how to overcome them. ↩

Discover the applications of tungsten carbide in the food processing industry. ↩

Explore the diverse industrial applications of tungsten carbide and its benefits. ↩