Are you struggling with poor cutting quality like burrs and waves? These issues can ruin your products and cause costly stops. The problem might be simpler than you think: your blade's flatness1.

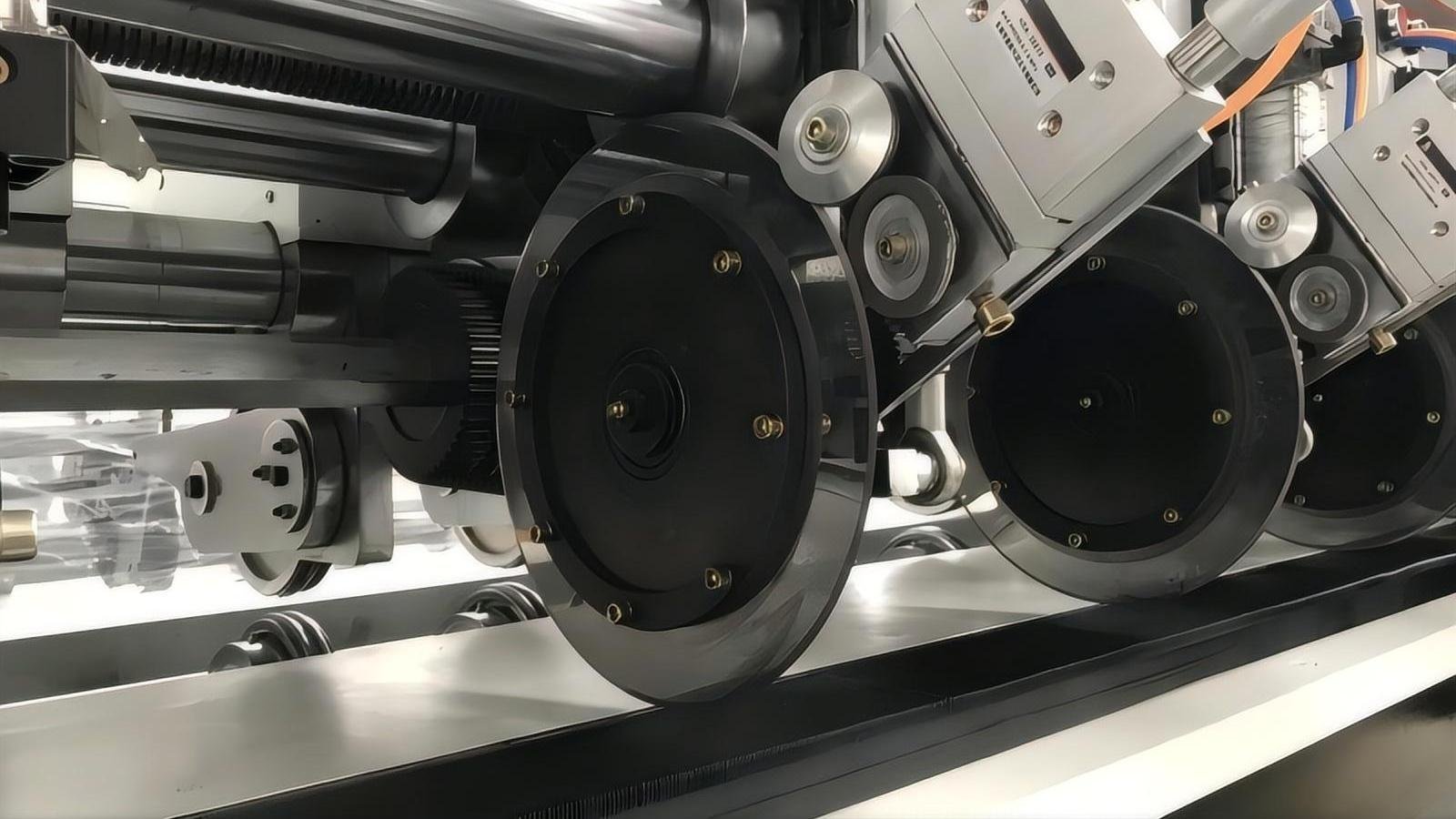

High flatness is essential for industrial blades because it directly impacts cutting precision, blade lifespan, and machine stability. A perfectly flat blade ensures uniform contact with the material, leading to clean cuts, even wear, and reduced vibration2, which protects both the blade and the machine.

Understanding why flatness matters is the first step toward better cutting performance. But you might wonder how a tiny bit of warping can cause such big problems, or how you can even check for it. Let's dive deeper into these practical questions. Answering them will help you improve your cutting process and choose the right blades for your needs.

How Does Poor Flatness Affect Cutting Quality?

Are your final products failing quality checks because of inconsistent cuts? This common issue leads to wasted material, customer complaints, and lost profits. Let’s explore how poor blade flatness is often the hidden cause.

Poor blade flatness creates uneven contact between the blade's cutting edge and the material. This imbalance leads to inconsistent cutting forces, which causes defects like burrs, wavy edges, and dimensional inaccuracies3, especially in high-precision cutting applications like film, foil, and paper.

When a blade isn't perfectly flat, it wobbles as it rotates or moves. This means that only certain parts of the cutting edge engage with the material at any given moment. These high-pressure points cut deeper or with more force, while the low points, or gaps, don't cut effectively. This chain reaction of uneven pressure is what ruins the quality of your cut.

I remember a client, Alan, who runs a plastic film slitting company in Germany. He called me because he was experiencing inconsistent slit widths and rough edges, which was causing major issues with his customers. His team had already spent weeks trying to recalibrate the slitting machine, assuming it was a mechanical problem. I suggested they check the flatness of the blades they were using from another supplier. Sure enough, we found that many of their blades were warped by just a few dozen microns. It sounds tiny, but for thin film, it's a huge deviation. We sent him a set of our PASSION blades, which are ground to a very high flatness tolerance. The problem disappeared overnight. His cuts became clean and consistent, proving that the blade was the root of the problem all along.

The Impact On Different Materials

Poor flatness affects materials differently. Here is a simple breakdown:

| Material Type | Effect of Poor Flatness | Ideal Flatness Requirement |

|---|---|---|

| Thin Films & Foils | Causes wavy edges, stretching, and inconsistent slit widths. | Very High (e.g., <0.01mm) |

| Paper & Cardboard | Leads to dusty or burred edges and potential tearing. | High |

| Textiles | Results in frayed or jagged cuts and material pulling. | High |

| Metal Sheets | Creates uneven shear, burrs, and potential blade chipping. | Moderate to High |

This shows that for industries requiring high precision, you simply cannot compromise on blade flatness.

What's The Impact Of Flatness On Blade Lifespan And Machine Stability?

Are you replacing your industrial blades more often than you should be? Or do you notice excessive vibration from your machines during operation? This downtime costs money and can damage your equipment. The flatness of your blade might be the root cause.

A blade with poor flatness experiences concentrated stress on high spots, causing rapid, uneven wear and chipping that shortens its lifespan. It also fails to mount flush against the machine's hub, leading to imbalance and vibration that can damage bearings and other critical components.

Think of a spinning blade that isn't perfectly flat. As it rotates at high speed, the warped sections act like tiny hammers, striking the material with uneven force. This concentrated impact creates intense localized heat and stress on small areas of the cutting edge. For hard and brittle materials like tungsten carbide, this stress can easily lead to micro-cracks4 and chipping, forcing you to resharpen or replace the blade long before its time.

Furthermore, the problem extends beyond the blade itself. Industrial blades are mounted onto a hub or clamp. If the blade's surface isn't flat, it can't sit securely. This creates a tiny gap, causing the blade to be mounted off-center or at a slight angle. When this imbalanced blade spins at thousands of RPM, it generates significant vibration. This vibration travels through the machine's shaft and into its bearings. Over time, this constant shaking wears down these critical components, leading to expensive repairs and unplanned downtime for the entire production line. A flat blade, on the other hand, mounts perfectly, spins true, and works in harmony with your machinery.

From Blade Wear To Machine Damage

The connection between flatness, wear, and stability is direct. A small deviation in flatness can start a cascade of problems that affect your entire operation.

| Flatness Tolerance | Stress Distribution | Blade Lifespan | Machine Vibration |

|---|---|---|---|

| High (<0.02mm) | Evenly Distributed | Long | Minimal |

| Medium (0.05mm) | Some High Spots | Reduced | Noticeable |

| Low (>0.1mm) | Highly Concentrated | Very Short | Severe |

Investing in high-flatness blades is not just about getting a better cut—it's about protecting your entire investment in your machinery.

How To Check The Flatness Of Industrial Blades?

You suspect your blades might not be flat, but you feel stuck. It seems like you need expensive lab equipment to know for sure. The good news is, there are both simple workshop methods and professional techniques to check flatness.

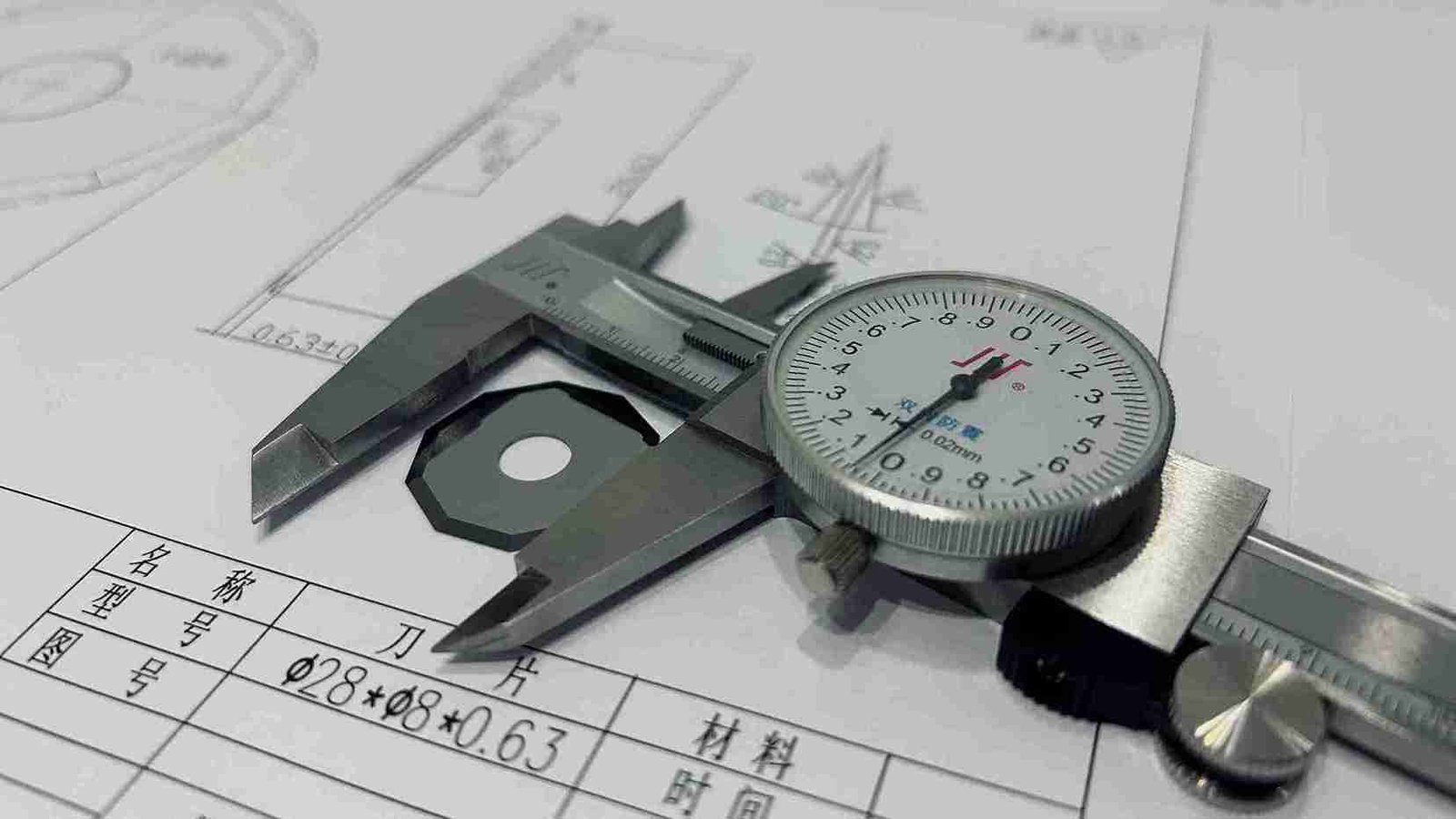

A basic flatness check can be done with a certified straightedge and a set of feeler gauges to find gaps. For a more precise measurement, the industry-standard method is to use a dial indicator5 on a calibrated granite surface plate to accurately read any surface deviation.

Knowing how to measure flatness is a valuable skill. It empowers you to verify the quality of new blades and monitor the condition of existing ones after sharpening. Performing these checks can help you catch problems early before they lead to poor product quality or machine damage. There are two primary methods you can use, depending on the precision you need.

The Straightedge Method (Workshop Check)

This is a quick and easy way to get a general idea of a blade's flatness.

- Clean: First, ensure both the blade and a reliable flat surface (like a workbench) are perfectly clean.

- Position: Place the blade on the surface. Lay a certified straightedge across the diameter of the blade.

- Inspect: Look for any light showing through the gap between the straightedge and the blade.

- Measure: Try to slide thin feeler gauges into any gaps you find. The thickness of the gauge that fits snugly is your flatness deviation.

The Dial Indicator Method (Precision Measurement)

This is how professionals, including us at PASSION, measure flatness to ensure it meets strict tolerances.

- Setup: Place the blade on a perfectly flat granite surface plate.

- Calibrate: Mount a dial indicator on a stand and position its tip on the blade's surface. Press down slightly and zero the dial.

- Measure: Gently glide the blade under the indicator without lifting it. Watch the dial for movement. The total range of movement from the lowest to the highest reading is the blade's total flatness error.

| Method | Precision | Cost | Best Use Case |

|---|---|---|---|

| Straightedge | Low | Low | Quick workshop checks, detecting major warp. |

| Dial Indicator | High | Moderate | Quality control, verifying precision specs. |

What Is The Difference Between Surface Finish And Flatness?

In the blade industry, people often use words like "smooth" and "flat" as if they mean the same thing. This confusion can lead to choosing the wrong blade, causing production issues. Let's clarify the critical difference.

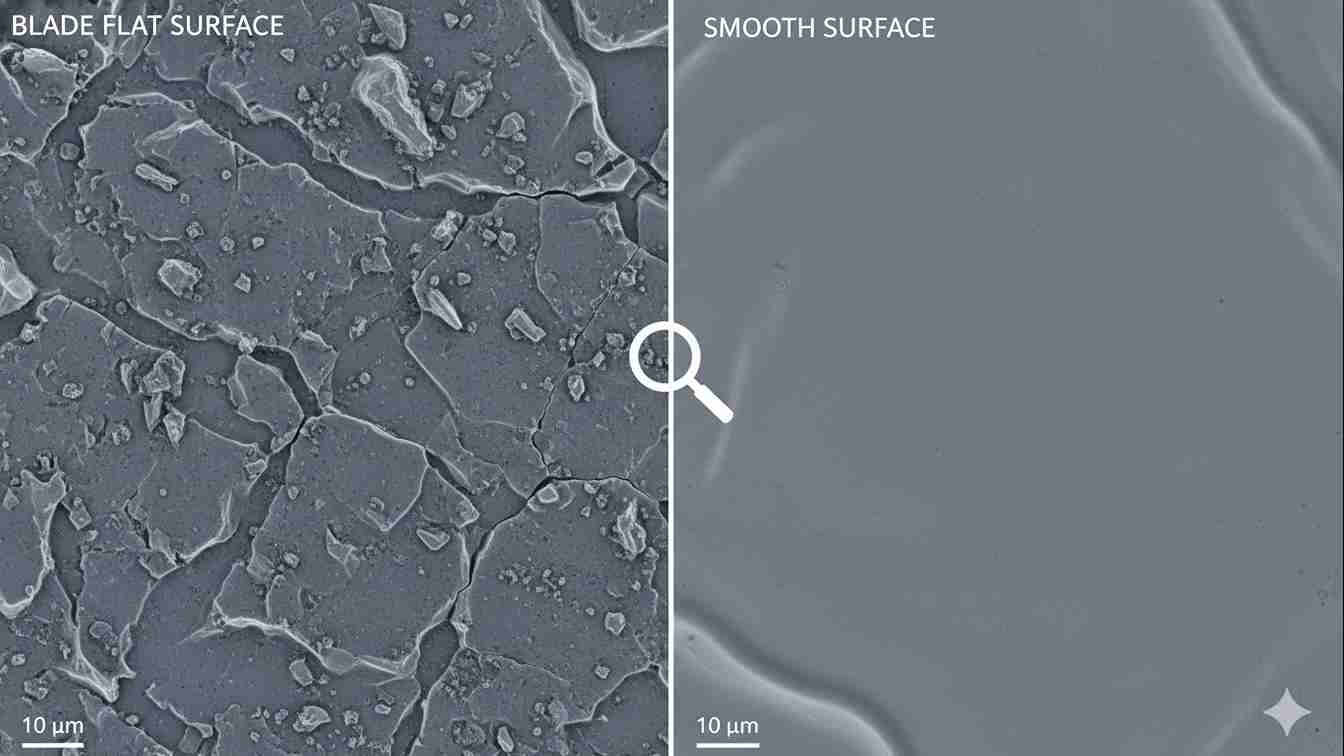

Flatness is a large-scale measurement of a blade's overall planarity, checking for waves or warp across its entire surface. Surface finish, or roughness, is a micro-scale measurement of the texture within a small area of that surface. A blade can be perfectly flat but still have a rough finish.

To make it simple, imagine a highway. The flatness of the highway is its overall evenness over several miles—are there long, gradual hills and valleys? The surface finish6, on the other hand, is the texture of the asphalt itself—is it smooth and slick, or is it coarse and bumpy? You could have a perfectly level, flat highway (good flatness) made of very rough gravel (poor surface finish).

In the world of industrial blades, both parameters are important, but they affect different aspects of performance. Flatness determines how the blade mounts and distributes pressure during a cut. It is the key to preventing vibration and ensuring a consistent cut depth. Surface finish, measured in Ra (Roughness Average), affects friction. A smoother finish (lower Ra value) reduces heat buildup, prevents material from sticking to the blade, and can provide a cleaner shear on certain materials. At PASSION, we control both properties very carefully to match the blade to its specific application. For example, a food processing blade needs an extremely smooth finish for hygiene, while a slitting blade needs top-tier flatness for precision.

Two Different Jobs, One Goal

Both flatness and surface finish work together to achieve the perfect cut, but they have distinct roles.

| Feature | Flatness | Surface Finish (Roughness) |

|---|---|---|

| Definition | Overall deviation from a perfect plane. | Microscopic texture of the surface. |

| What It Affects | Mounting stability, vibration, even wear. | Friction, heat generation, material sticking. |

| How It's Measured | Dial indicator, straightedge. | Profilometer, surface roughness tester. |

| Common Unit | Millimeters (mm) or Inches (in). | Micrometers (µm) or Microinches (µin) Ra. |

Understanding this difference is crucial when specifying your blade requirements. If you are having vibration issues, check the flatness. If material is sticking to your blade, look at the surface finish.

Conclusion

High blade flatness is not a luxury; it's essential for precision cutting, longer tool life, and stable machine operation. Always verify this critical parameter to achieve the best production results.

Understanding blade flatness can significantly enhance your cutting precision and product quality. ↩

Explore the effects of vibration on machinery and how to minimize it for better performance. ↩

Understand dimensional inaccuracies and how to ensure precision in your cuts. ↩

Learn about the causes of micro-cracks and how to extend the life of your blades. ↩

Learn about the dial indicator's role in achieving precise measurements of flatness. ↩

Understand the critical differences between surface finish and flatness for better blade selection. ↩